3D-printed Injection Molds Save Medical Device OEMs Time and Money - plastic mol

Author:gly Date: 2024-09-30

Among other things, the importance, utility and enhanced safety offered by prefilled and labelled medication syringes is emphasised, as well as the use of aids such as colour-coded medication trays that can help the anaesthetist correctly organise the syringes before and during anaesthesia. Neither prefilled syringes nor these coloured aids are yet in widespread use in the UK NHS.

DeviceTalks is a conversation among medical technology leaders. It's events, podcasts, webinars and one-on-one exchanges of ideas & insights.

The authors say: “’First do no harm’ is what doctors strive for. We hope that these guidelines provide useful points for anaesthetists’ individual practice, while acknowledging that patient safety also relies on supportive systems within their hospitals.”

Subscribe to Medical Design & Outsourcing. Bookmark, share and interact with the leading medical design engineering magazine today.

This website uses cookies to give our readers the best website experience. Please refer to our privacy policy to find out how we use cookies and how you can edit your preferences.

The guidance, which was now published in Anaesthesia (the journal of the Association of Anaesthetists), has been written by a working party of UK anaesthesia experts that include Dr Mike Kinsella, Honorary Consultant, Department of Anaesthesia, University Hospitals Bristol and Weston, Bristol, UK and Chair of the Working Party.

The Medical Device Business Journal. MassDevice is the leading medical device news business journal telling the stories of the devices that save lives.

Accumold’s history in the micro optics marketplace spans decades, and the company has proudly partnered with leading SMEs and major international corporations to craft ground-breaking products that push the boundaries of innovation. In the photonics sector where supreme precision is not just desired but required, Accumold has cemented its role as the micro molding authority for OEMs seeking to create components that are not only complex and diminutive but also precise, timely, and cost-effective.

This guidance has been produced by the Association of Anaesthetists in response to requests from members in view of continuing incidents of medication errors and patient harm. It ties in with the World Health Organization (WHO) 3rd Global Patient Safety Challenge 'Medication Without Harm', which was the theme of the WHO World Patient Safety Day September 2022.

Runyan concludes, “The exacting tolerances inherent in micro-optic applications, necessitate that OEMs collaborate with seasoned experts like Accumold from the outset to achieve precise, timely, and cost-effective manufacturing outcomes. We invite all Photonics West attendees to join us at booth 1566, where we’re excited to showcase our successes in micro molding and discuss how our expertise can elevate your micro-optics projects. Engage with our expert team and let’s explore how our partnership can illuminate the path to your product’s success.”

Rutgers researchers have found a way to reduce bleeding in patients following bariatric surgery. The study, which appeared in the journal Surgery for Obesity and Related Disorders, was conducted by…

The authors explain: “Peri-operative medication safety is complex. Avoidance of medication errors is both system- and practitioner-based, and many departments within the hospital contribute to safe and effective systems. For the individual anaesthetist, drawing up, labelling and then the correct administration of medications are key components. These guidelines aim to provide pragmatic safety steps for the practitioner and other individuals within the operative environment, as well as short- to long-term goals for development of a collaborative approach to reducing errors. The aim is that they will be used as a basis for instilling good practice.”

Copyright © 2024 WTWH Media, LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media LLC. Site Map | Privacy Policy | RSS

The authors say that labelling errors have been noted in around 1–1.25% of peri-operative medication administrations and medication substitutions in 0.2% of administrations during anaesthesia, although precise figures are lacking as research studies use different methodologies. It is important to acknowledge that every practitioner is open to error and that the risk can increase over time during a case, especially in the presence of specific factors that diminish performance such as fatigue. The authors say: “Understandably, there is considerable emphasis on medication errors. However, it is also important to give appropriate recognition to the fact that in virtually all cases the correct medication is given by the correct route, at the correct time. Good practice should be highlighted; in most cases there is a consensus on what this looks like.”

Medication errors sit among the top ten causes of harm to patients. They can, of course, occur in any department, but it’s still a surprise that they happen as frequently in anaesthetics…

A study led by the University of Birmingham provides strong support for current recommendations on treating patients with an underactive thyroid and validates latest UK and US guidelines, say…

Paul Runyan, VP Sales & Marketing at Accumold, says. “The critical importance is to integrate seasoned micro-optic suppliers like Accumold into the design phase as early as possible. It’s our partnership approach, versus a mere vendor relationship, that enables the fusion of specialized micro manufacturing and micro-optic expertise into your projects for solutions that are both efficient and economical. We are able to produce micro-optic marvels such as 250-micron fiber optic lenses, parallel arrays, demux devices, and diffractive lenses, enhanced by our experience in molding attenuated resins and applying coatings like IR, AR, and reflective layers onto plastic substrates. The complex demands of crafting micro-sized optical couplers, embedding lenses into housings, replicating lens profiles to a quarter wave accuracy, and achieving lens surface finishes within 50 angstroms are why we have dedicated tooling specialists to ensure your light transmission projects are flawlessly executed.”

Beyond tooling intricacies, the meticulous nature of the molding process, precise metrology, and automated post-molding assembly are essential to maintaining the integrity of micro-optics from conception to final assembly. Partnering with Accumold means engaging with a leader in the field, a company whose three-decade legacy in micro molding brings unparalleled experience and the capability to scale production to meet any demand. This reassurance of stability and efficiency translates into cost-effective solutions for Accumold’s customers.

The opinions expressed in this news release are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.

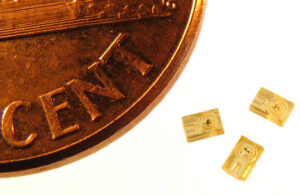

On booth 1566 at Photonics West, Accumold will be showcasing its expertise as the world’s leading high-tech manufacturer of precision micro molded plastic components with part geometries from 5cm to less than 1mm in size. The company’s 30-plus years at the forefront of micro molding innovation ensures that it leads with expertise in insert molding, clean room molding, and 2-shot molding across materials like PEEK, Ultem, LCP, and a wide range of engineered thermoplastics.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly