Two-Shot Injection Molding - two shot plastic injection molding

Author:gly Date: 2024-10-15

Customer cases have demonstrated that the switch from fossil-based plastics to PLA for injection molding is very much possible, all without major financial investments.

A Release Agent facilitates the separation of the cured part from the mold. SUKANO® Mold Release Masterbatch migrates to the surface of the final product facilitating demolding of the injection molded part from the metal surface of the cavity, hence reducing the demolding force.

Phone +1 864 486 1478 Fax +1 864 486 3681 americas@sukano.com

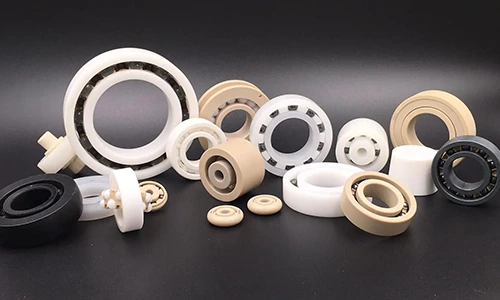

The development of AI has accelerated the arrival of the era of robotics. By adopting lightweight materials without sacrificing the original structure and performance, robots can reduce operational energy consumption. Among these materials, PEEK will fully demonstrate its remarkable abilities in this field.

PEEK, with its creep resistance, ability to withstand various liquid media, and high-temperature resistance, becomes an almost perfect material. However, considering its high cost, it is therefore extensively used in special structural components and performance parts.

No. 7, Jalan Hasil Kawasan Perindustr. Jln. Hasil 81200 Johor Bahru, Johor Malaysia

We offer PEEK standard injection molding, PEEK insert molding, PEEK overmolding, PEEK family molding and even PEEK CNC machining solutions.

Phone +41 44 787 57 77 Fax +41 44 787 57 78 emea@sukano.com

295 Parkway East Duncan SC 29334 USA

Chaltenbodenstrasse 23 8834 Schindellegi Switzerland

The high-temperature processing of PEEK may not be suitable for all injection molding part suppliers, as it places high demands on injection molding capabilities. FirstMold, with hundreds of case applications of PEEK material, is well-versed in the properties of PEEK and has substantial practical production experience. Our high-performance machines, knowledgeable professionals, and experienced mold design engineers perfectly match these requirements.”

A bigger shift toward PLA in injection molding has been slowed by serious processing issues. There are several challenges that convertors have faced when processing injection molded PLA parts, especially when using existing equipment and tools, including:

We receive 20-30 PEEK project requests from clients every year, ranging from simple gear molding to complex aerospace specialty performance parts.

SUKANO ® Mold Release Masterbatches can reduce the friction between the polymer chains. This leads to a lower melt viscosity and therefore a higher melt flow without increasing the temperature. This can help to fill the cavities, especially in thin wall applications.

Our first PEEK injection molding case dates back to August 2014, involving a relatively simple automotive clutch gear seal ring product.

Phone +60 7 238 60 99 Fax +60 7 234 57 70 apac@sukano.com

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly