Plastech Molding Solutions, 50 Mellen St, Hopedale, MA ... - plastech molding so

Author:gly Date: 2024-10-15

In comparison to other Nylon grades, PA 11 has lesser desirable mechanical properties but it has various advantages such as being lightweight and lower water absorption rate.

No two custom injection molding projects are the same, so working with someone that understands all the aspects of part design and manufacturing is important.

Being skilled in all aspects of the plastic molding process allows us to help you with design, selecting materials, and any questions you may have. Contact us to get started on your custom part.

Polyamides are a very popular injection molding material but just like any other plastic material, they are not suitable for every application. There are various issues that can arise in the nylon injection molding process. Some of the challenges and considerations that one must take into account before applying Nylon resins to an application are listed below:

You might want to test your concept with a prototype to make sure that it fits and functions well. The cost of a prototype for injection molding depends on two things: the completeness of the design and the size of the part being designed.

Nylon is a hygroscopic material that must be dried properly during processing to maintain its physical properties. In appearance, nylon plastics can be either white, milky white, or yellowish, and are either transparent or translucent crystalline resins. These Nylon resins can also be imparted with any color.

It is polymerized either through omega trinitrophenyl aminolauric or laurolactam monomers. They both have 12 carbons, hence the name ‘Nylon 12’.

If your project requires plastic parts to endure high temperatures and resistance to chemicals and abrasion, Nylon can be a perfect choice. VEM Tooling has the expertise and the team that is required for your Nylon injection molding project. At VEM Tooling, we offer quick quotes and dependable service.

Standardization and quality are part of our companies core values. We deliver the best possible experience and product to our customers, every single time consistent. Take a look at our certificates!

Nylon 46, also referred to as Polyamide 4/6 is a semi-crystalline, yellowish thermoplastic. It is made through condensation polymerization of 1,4-diaminobutane with adipic acid.

Commodity grade resins are typically less expensive than engineering grade resins. However, engineering grade resins will likely be able to withstand extreme temperatures and friction better than commodity resins. Understanding the purpose and function of the part will ultimately determine the best material for it.

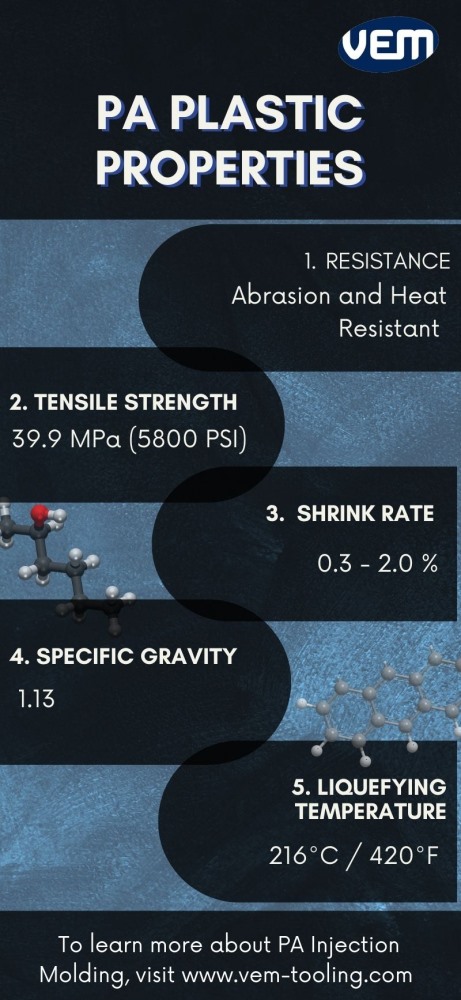

Nylon resins exhibit excellent strength, stiffness, heat resistance, resistance to wear, and chemical resistance to hydrocarbons. Nylon is a relatively low-cost polymer that is easy to process and can be reinforced with glass or carbon fiber to increase mechanical and thermal properties. Let’s take a look at some of its properties through the below infographic:

The very first example of Nylon that was developed by Dupont’s team was Nylon 66. Later, many other variations were developed. Today, nylon comes in four main grades: Nylon 11, 12, 46, and 66. Nylon can be reinforced with glass for greater mechanical strength and that refers to the various grades of Nylon. In addition, there are many varieties of PA such as PA6, PA66, PA610, PA11, PA12, PA1010, PA612, PA46, PA6T, PA9T, and MXD-6 aromatic polyamide, etc.

When the part is ready for the manufacturing process, the plastic mold needs to be built. One of the biggest drivers of cost is the size of the part. If a part is bigger, it’s going to require more material, tooling, and time to build the injection mold.

Nylon is a hygroscopic substance as it readily absorbs water from its environment. Hygroscopic materials tend to attract water either through absorption or adsorption. Nylon is also known in the injection molding industry for its many variations. In this article, we have described such features and their various types in-depth.

One of the major differences between the two types of Nylon is mold shrinkage. The mold shrinkage of Nylon 6 is lower than Nylon 66 and thus, the dimensions of the final plastic part manufactured are generally as expected with Nylon 6. In the case of Nylon 66, you need to account for the higher mold shrinkage.

In addition, if the demand for a part is very high (hundreds of thousands of pieces), a multi-cavity tool may be required which also increases the cost.

For large parts with a simple design, the mold could cost between $30,000 – $100,000. If the part is large but has no design work, it will have an additional $10,000 added for design.

There are very few plastics in the manufacturing industry that combine the versatility, performance, and value of Polyamides.

Nylon 6 & 66 are both synthetic polyamides that are semi-crystalline and possess great strength and excellent durability.

Some parts may require cams, lifts, or core pins, which are additions to the custom injection mold that help achieve certain features a part may require. If the part has a higher volume, the mold would require more cavitation (parts molded per cycle) which adds to the molding cost and parts handling equipment (conveyors, chutes, bowl feeders, robots, etc.).

Polyamides, also referred to as Nylon in the manufacturing industry can be processed through standard injection molding. It demonstrates various chemical and physical properties that make it an ideal choice for manufacturing both, thin- and thick-walled parts.

Since its invention, Nylon 6 has been applied to various industries. It has been a popular choice and has been applied to various projects such as surgical sutures, musical instrument strings, toothbrush bristle threads, fishing nets, and filaments. In addition, it is a popular choice in the textile industry for hosiery and knitted garments.

After hydrolysis, hydrogen bromide undergoes nucleophilic substitution with ammonia to form 11-aminoundecanoic acid, which is polymerized into nylon 11.

While Nylon 6 and 66 are primarily very similar, they also have distinct differences. These differences are largely due to the differences in their chemical structure and are illustrated through the following infographic:

We ensure that you have a seamless manufacturing process from prototype to production. You can contact us to further understand how Nylon Injection Molding can be implemented for your project. Contact VEM tooling and request a quote today.

Nylon is a type of plastic that is composed of polyamide resins, which is obtained either through the polycondensation of diamines and dibasic acids or through the ring-opening polymerization of lactams which is formed by the dehydration of amino acids.

Nylon was developed by DuPont and is a generic name for polyamides. DuPont refers to E. I. duPont de Nemours, an American company that was founded in July 1802. Since the 20th century, DuPont has invented various types of polymers that are extensively applied to a wide array of industries. Some of the popular plastics besides Nylon are Lycra, Teflon, Freon, Neoprene, etc.

If a design is flawless, it will likely be easy to get a prototype 3D-printed. On the other hand, if a lot of design work is needed before it can be printed, designing could be the most expensive part of the process. Here are a few scenarios that illustrate this:

Similarly, the more complex the part is, the more time it takes to make the plastic injection mold – and, well, time is money.

Nylon 66 exhibits excellent abrasion resistance thus, Nylon 66 polymer is extensively applied to carpets, upholstery, and conveyor belts.

The numbers 6 and 66 refer to the type and quantity of polymer chains in their chemical structure. Nylon 6 is made from one monomer which has 6 carbon atoms whereas Nylon 66 is made from 2 monomers in which each one has 6 carbon atoms, thus it’s called Nylon 66.

Nylon injection molding has various benefits and limitations. Though, polyamides are a popular material choice for injection molding techniques, we must note that it has both advantages as well as disadvantages.

In looking at parts with simple designs, a small part with simple design could have an injection mold cost between $10,000 – $20,000. A small part with no design work could have the same mold cost with $2,000 added for design.

Nylon was patented by DuPont in 1935 and has since then been one of the most popular plastics to be used in various industries.

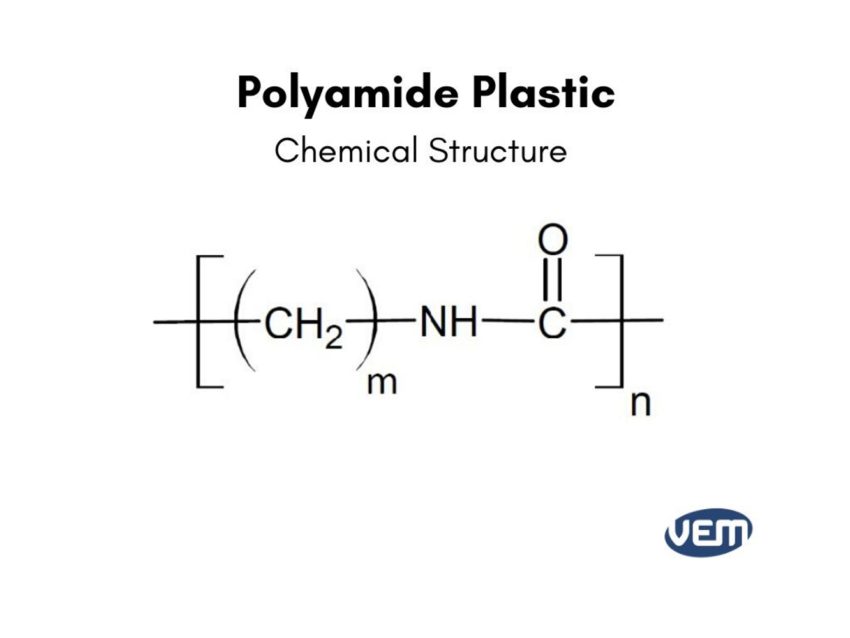

Polyamide, abbreviated for PA, is a popular injection molding material. A polyamide is a type of polymer that has amide groups in a recurring form in the main polymer chain. The chemical formula for amide groups is (R―CO―NH―R′) and the chemical structure of polyamides is as follows:

Resin pellets are the beginning of everything plastic. Once heated, Resin is a free-flowing polymer used in plastic part production. In the injection molding industry,

Plastic injection molding is a custom option for manufacturing parts, and can be much more versatile than other types of plastic molding. This more efficient

Nylon 11 also referred to as Polyamide 11 or PA 11 is a non-biodegradable polyamide. Nylon 11 has lesser amides in its structure and it thus exhibits increased resistance to dimensional changes that are often observed due to moisture absorption.

In the world of manufacturing, efficiency, cost-effectiveness, and quality are key. This is where hot runner systems in injection molding come into play, revolutionizing the

A turnkey injection molder, like Pioneer Plastics, are full-service manufacturers who build the mold and handle the injection molding process. Keeping the part in-house from beginning to end makes the process more time-efficient and cost-efficient.

In looking at parts with complex designs, a small part with complex design could have a mold cost between $20,000 – $40,000 . A small part with no design work could have the same mold cost with $2,000 added for design.

With over 100 different varieties of resin, it can be difficult to determine which one is best for your plastic part. Once we understand the characteristics that the part requires and the end use of the part, we can help you narrow down choices and choose the ideal plastic material for it. Some examples of these characteristics are:

The next major differences are the water absorption rates and heat deflection temperatures. Nylon 6 tends to absorb more water and has lower heat deflection temperatures than Nylon 66. It is thus not suitable for applications that require the plastic to be exposed to water at high temperatures.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly