Medical plastics injection molding for medical devices - medical device molding

Author:gly Date: 2024-10-15

If the two materials are somewhat compatible and you simply need to increase the strength of the bond, try maximizing the surface area in the transition zone.

Incorporate an accent groove, 1.5 mm – 2.0 mm deep and 0.8mm – 1.0mm wide, in the first shot profile along the edge of the second-shot.

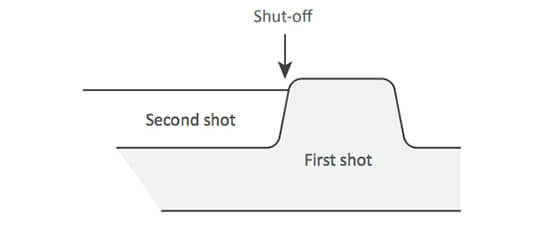

Solution: Create a sharp transition between the first and second shot materials in the shut-off areas. To accomplish this, incorporate a step or accent grove into your design:

Like most plastics manufacturing processes, injection molding has its share of problems and solutions. Same goes for two-shot injection molding — and there’s even more complexity. The key areas to consider when troubleshooting injection molding defects are captured in our Two-Shot Injection Molding Design Guide. Be sure to download your copy today. In the meantime, here are some common two-shot molding defects – and how to avoid them.

Cause: Unfortunately, all tab gates produce this defect, known as vestige, on the surface of the part. They’re somewhat of a necessary evil.

Plastech specialises in the manufacture of mould tooling from prototype to full high volume tools. We produce variations including:

As for any engineered plastic part, material selection is paramount. Typical considerations include mechanical and physical properties, , heat, electrical, flammability and chemical and UV resistance. For two-shot, if we’re to avoid defects, we must take it a step further and consider the compatibility between the first shot and second shot material.

Two-shot injection molding defects often occur in the shut-off areas where the second shot mold seals against the first shot, or the substrate.

As discussed in our Two-Shot Injection Molding Design Guide, the type of gate, its design, and location must be carefully considered to achieve the ideal cosmetic appearance and dimensions of your part. In single-shot injection molding, the gate is typically located so that the melt enters at the thickest part of the cavity and then flows to the narrower areas. Its placement in two-shot isn’t as straightforward.

Plastech has more than 30 years’ experience and knowledge in design, sourcing and manufacture of mould tooling. All mould tooling manufacture is managed, monitored and checked by UK personnel on site in China to ISO 9000 quality standards.

Once the tooling is accepted, sea or air freight will be arranged and all necessary shipping and customs documentation prepared. Tooling is shipped from China to Plastech UK where it is re-checked and inspected before being forwarded to the client for commissioning. The tool will be supplied with a full set of CAD data and steel certificates. Tooling is guaranteed to client requirements under the terms detailed in the final accepted quotation.

Two-shot design can deliver a competitive advantage far above other molding processes, especially for complex parts. Learn the benefits of the process and explore the special design requirements needed to make it work in this free guide created by engineers, for engineers.

Solution: The solution to the first-shot vestige is quite simple – position it so that the second shot material covers it! The second-shot vestige, however, will require additional processing after the mold cycle. The only way around the vestige all together is to use a hot tip gate, depending on the part design.

Tooling is manufactured at Plastech China. All tooling is guaranteed to client requirements and supported by Plastech UK engineers. Plastech China tool rooms are accredited to ISO 9000 quality standards.

Cause: Usually a poor seal between the first shot and the second shot mold. Or, the material is too thin in the shut-off area.

To enable clients to closely monitor the progress of their tooling, Plastech China produces weekly plans and images. Plastech will also forward samples for your appraisal, along with video footage of trial and inspection reports. For clients who wish to witness trials first hand, we can arrange visits, organise and obtain visas, book hotels and arrange transport and translation services.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly