Top 8 Plastic Injection Molding Companies - molding company

Author:gly Date: 2024-10-15

In addition to overmolding inserts, the machine series can also be used to mold fiber mats into three-dimensional structures

Our customers particularly appreciate the insert's ergonomic working height and spacious mold area. Another advantage is high energy efficiency thanks to ecodrive.

The injection unit of our insert machine can be installed either vertically or horizontally. It guarantees very good injection performance due to sophisticated barrel cooling and excellent plasticizing performance thanks to optimized screw geometries.

Our servo-hydraulic drive concept, ecodrive, keeps your energy costs low. Thanks to intelligent pump control, we achieve low power loss and hardly any noise or heat emissions. You save expensive energy, use less cooling water and protect the environment.

We offer a wide range of equipment for automated part handling: From safety guards to conveyor belts and robots to complete injection molding cells.

The performance of our vertical injection molding machine shown with a production cell for cell phone covers made of organic sheets.

The clamping unit was specially developed for vertical installation. It ensures uniform clamping force distribution and high platen parallelism. The insert machine is therefore particularly suitable for overmolding inserts with multiple molds.

Our customer portal provides ENGEL customers with a wide range of additional information on our injection molding machines:

Vertical machines for overmolding inserts have limited options of water supply for temperature control due to the design. On our insert series, the hoses can be supplied to the mold from below and from above. That is optimal for temperature control. You avoid unnecessary scrap and energy consumption.

Our servo-hydraulic drive concept, ecodrive, keeps your energy costs low. Thanks to intelligent pump control, we achieve low power loss and hardly any noise or heat emissions. You save expensive energy, use less cooling water and protect the environment.

Thermoset plastics are generally stronger than thermoplastic materials due to the three-dimensional network of bonds (crosslinking), and are also better suited to high-temperature applications. They have high mechanical strength and rigidity and are frequently used to replace metals, reducing the weight by as much as 75%. Thermoset materials are often used in vehicle engine compartments, oil pump and thermostat housings, water inlets & outlets and impellers. Brake linings and disk brake pads can also be manufactured in thermoset plastic.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The insert injection molding machine is adapted precisely to your requirements. There are many options available: horizontal or vertical injection unit, multi-color design, with shuttle table or rotary table, for manual part handling or special automation. We deliver a customized vertical injection molding machine.

Our vertical injection molding machine is designed to use as little space as possible. Versions with a vertical injection unit require very little floor space. The insert is therefore not only a solution for overmolding inserts, but also for small production spaces.

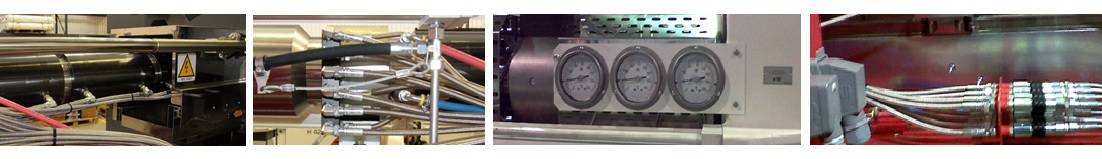

Figure 1. Injection Unit Figure 2 & 3. Thermoregulated screw and distribution Figure 4-7. Thermoregulated barrel and distribution

Our insert series is the best choice for insert molding. The wide range of options and the flexible machine concept allows you to adapt the machine to your requirements. The integration of special automation is easily possible too. You get an economical production cell and make a reasonable investment.

The insert injection molding machine is adapted precisely to your requirements. There are many options available: horizontal or vertical injection unit, multi-color design, with shuttle table or rotary table, for manual part handling or special automation. We deliver a customized vertical injection molding machine.

Vertical machines for overmolding inserts have limited options of water supply for temperature control due to the design. On our insert series, the hoses can be supplied to the mold from below and from above. That is optimal for temperature control. You avoid unnecessary scrap and energy consumption.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Our vertical injection molding machine is designed to use as little space as possible. Versions with a vertical injection unit require very little floor space. The insert is therefore not only a solution for overmolding inserts, but also for small production spaces.

Negri Bossi provide special applications for thermoset injection molding. This solution includes all the equipment required for reliable and optimal production of high-quality molded parts.

Ergonomic working height and generous access for handling inserts. An operator platform is not required. Available as a single station, with shuttle table or rotary table. Simple integration even of complex automation.

The CC300 is an innovative machine control unit with modern operating logic, self-explanatory navigation and customizable configuration options. Robots and peripherals are fully integrated.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly