Tag - top 100 injection molding companies - top 100 injection molding companies

Author:gly Date: 2024-10-15

Similarly, The Rodon Group optimized targeting for specific industries with videos to encourage engagement and diversify content. According to HubSpot, marketers who incorporate videos into their content strategies have seen 49% faster revenue growth than those who don’t.

In thermoset injection molding, components with very high mechanical properties can be manufactured. In addition, thermosets are:

Connect with the most active and qualified network of B2B buyers on the world's leading platform for product discovery and supplier selection.

![]()

Pellet-based molding compounds and wet polyesters (bulk molding compounds; BMC) are usually reinforced with various fillers. These are, for example, minerals, glass or even carbon fiber. This provides them with high mechanical properties .

According to MarketWatch, the Plastic Injection Molding Sales Market is the most booming and promising sector of the industry. So to make sure you’re ahead of competitors, contact us for a free digital health check. Our industry experts have been connecting buyers and suppliers for more than 122 years.

Content marketing encompasses blogs, eBooks, videos, and infographics, and contributes to a stronger online presence for your manufacturing brand when other digital marketing strategies like SEO and online ads work in tandem. Digital marketing ensures you stay connected with customers and continue getting seen by new prospects — and more manufacturers are investing in its technologies. Due to the in-person limitations of COVID-19, reports show that manufacturers are no longer able to avoid digital marketing’s reach and effectiveness and have adjusted their approach from dated tactics like print ads to generating new customers using their website, social media, and digital ads.

Thomas Tip: Get ahead in the plastic injection molding industry with videos of your services. Thomas offers video production for free with the purchase of an advertising program.

Solid silicone rubbers (HTV) are high-temperature crosslinked and differ from liquid silicones in their molecular structure.

Injection molding produces many products standard in everyday households and industries. Injection-molded parts can be found in military, defense, and aerospace applications just to name a few. In 2018, medical equipment sourcing spiked as the healthcare industry boomed, driven by an aging population’s demographic wave requiring medical care. Then the COVID-19 pandemic accelerated the demand for medical devices and manufacturers turned to plastic injection molding to meet the demand for durable, lightweight, and malleable material.

How do you work? What’s the quality of your services and products? Which industries do you have expertise in? Content marketing can persuade potential partners and influence buyers at every stage of the buying cycle.

The industry’s growth has an upward trajectory. Last month, RFI submissions on Thomasnet.com for plastics molding services were up 80% year-over-year. As U.S. companies find that they can manufacture injection molded products more profitably right here at home, how can these companies market their services to take advantage of the opportunities?

According to a DemandGen Report, 67% of B2B buyers rely more on content to research and make purchasing decisions than they did a year ago. That's why your website's content is crucial for lead generation to reach the right buyers and increase market share and profits.

“Our goal in acquiring other companies is to increase our support and capabilities for our customers across the country, so, in return, they will bring their manufacturing business back to the United States,” Plastic Molding Manufacturer (PMM) CEO George Danis told Plastics Today. PMM had deals of acquiring a plastic company with facilities across New England in 2020.

For some industries, certifications are a legal or contractual requirement. Injection molding companies seeking to increase their sales and expand their market share of other industries can solidify their expertise with quality certifications, like:

Injection molding plays a significant role in the automotive industry too, which will encompass a bigger electric market in the next few years. Common components that use customized injection molding applications in the automotive industry include glove compartments, door handles, wheel trims, and many more.

The production of 64 cavity umbrella valves made of liquid silicone with a part weight of just 0.06 g requires high precision and efficiency.

See how D&M Plastics uses infographics throughout their website to simplify the complexities of plastic injection molding and engage B2B buyers looking for leading suppliers in that industry. B2B buyers like procurement managers research to familiarize themselves with new products or services. Rather than sifting through text-based information, a creative infographic presents all the data and stats buyers need in an engaging way.

Copyright© 2024 Thomas Publishing Company. All Rights Reserved. See Terms and Conditions, Privacy Statement and California Do Not Track Notice. Thomas Register® and Thomas Regional® are part of Thomasnet.com. Thomasnet Is A Registered Trademark Of Thomas Publishing Company.

When labeling a product or system as certified to an ISO standard, don't just say "ISO certified" or "ISO certification." Be clear and say "ISO 9001:2015 certified" or "ISO 9001:2015 certification" (for example). Showcase the PDF certifications and icons on your website and Thomasnet.com Company Profile so you can effectively target buyers in the industries sourcing certified suppliers.

“About half of our new custom work comes from Thomasnet.com leads. We could not have competed for — and won — all the new business we have without our strategic Thomasnet.com program.”

LSR (liquid silicone rubber) is processed using the LIM (liquid injection molding) method. The silicone is supplied as a homogeneous 2-component material. These two components are provided by special pumps.

ENGEL offers additional products such as universal injection compression and venting programs, wear-resistant plasticizing units, temperature-controlled nozzles, and corresponding peripheral equipment.

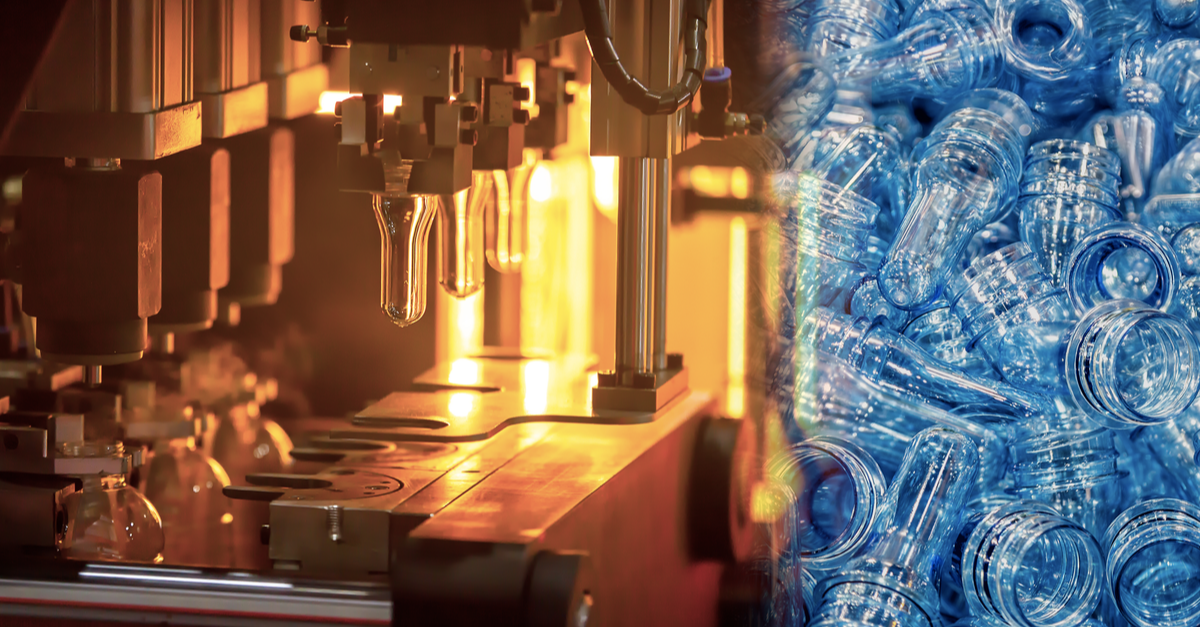

When they think of plastics, most people have packaging products or caps in mind. Thermoplastics are used to produce these items. But the world of plastics offers more than just standard materials. WWith elastomer and thermoset injection moulding you can process silicone, rubber or polyester resins. ENGEL has the injection molding technology solutions for this in its portfolio.

A Thomasnet.com Company Profile gets you in front of more than a million B2B buyers sourcing industrial services like plastic injection molding. Get Listed For Free.

Take advantage of our expertise, machines, and technologies. We will be happy to advise you on the design of your production cell.

In recent decades, American companies offshored a huge portion of their injection molding, but today, many companies are weighing the benefits of reshoring versus offshoring, and there has been an upward trend of reshoring and demand for services in the plastics and molding services industry. Mergers and acquisitions in the industry are also contributing to growth.

Rubber is used in sealing and engine technology. There are many different types, for example ethylene propylene diene monomer rubber (EPDM) or nitrile butadiene rubber (NBR). They are all processed in the same way.

Our injection molding machines can deal with the special properties of thermosets in injection molding. We offer wear-resistant and flexible systems for these challenging materials.

UNLOCK: See which companies are looking for your injection molding services with our free customer in-market buyer report.

Maximum output and highest precision - 32 infusion valves, slit during the processing, are produced on an all-electric e-mac 130.

Companies who are certified ensure their customers consistently receive high-quality products and services and the benefits are two-fold because the requirements of certain certifications also benefit managers and employees. For example, because the ISO 9001 certification specifies the requirements for an effective quality management system, employees benefit from the improved processes and management garners the benefits of saved costs.

Non-thermoplastic plastics include liquid silicone rubber (LSR), solid silicone (HTV), rubber, and bulk molding compound (BMC). These materials can be processed by injection molding if the machine is designed accordingly. They have one thing in common: temperature control in the machine works differently than in thermoplastic injection molding. The material is cooled in the barrel while the mold is heated. The machine design requirements are therefore different. ENGEL has the right solution for rubber injection molding with its elast machine series.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly