Sustainable Plastic Packaging | PTI Home Page | Plastic ... - pti injection mold

Author:gly Date: 2024-10-15

At FABEXCO, we specialize in plastic extrusions. Our passion lies in crafting profiles that set us apart from the competition. We relish challenges and thrive on projects with unique specifications, tight deadlines, and unconventional requirements. Our commitment to excellence drives us to deliver results that others simply can't match.Our profile extrusion capabilities are vast and... $$$

This is, no doubt, a big expense for any business. Therefore, most manufacturers outsource the injection molding process to experts like 3ERP with high-end injection molding machinery. Outsourcing makes injection molding a cost-effective option, in which the client can source the lowest cost for the part required and minimize the variable costs of production.

CNC machining has a little drawback in terms of the machine cycle for making molds. These machines require setup time for the tooling and changing the tools for different cut shapes.

Get in touch with 3ERP today to get an injection molding quote for your project. Whether it is a simple injection molding project or something that deals with inserts or overmolding, we handle it all!

CNC machining is usually employed for metal molds. A stainless steel mold or an aluminum mold would be typical. For example, machining an aluminum mold uses cutting tools to remove material from an aluminum block. This method of machining creates aluminum molds with unmatchable preciseness.

A trusted source for superior injection molding, compression molding and transfer molding with 45 years of molding experience and ISO 9001:2000 certification. We offer both Thermoset & Thermoplastic injection molding. Custom precision molded plastic components of all sizes for customers of all sizes.

Setup Costs: There are specific setup requirements for every step of injection molding. For instance, when making the molds, some setup of tooling is required. And setting up the mold and configuring the equipment during injection molding all involve an operator’s time.

Plastic coating is the application of liquid polymers or plastic onto the surface of a workpiece through dipping/immersion. The result is a thick plastic finish for protective and decorative purposes. This gives the material additional...

There is small-scale injection molding equipment that businesses keep in-house. Then there are large injection molding machines typically used by service providers and those in the large-scale manufacturing industry with large production volumes.

Using technologies like insert injection molding and overmolding helps save costs in the long run. For instance, insert molding eliminates the need to create threads on the plastic for attaching it to metal parts.

Multi-cavity molds and family molds allow you to multiply the production rate and reduce the cycle time. This can reduce the cost of the entire operation by a significant margin, especially in medium to large production runs.

While the process is cheap compared to its alternatives, you can further reduce the costs. For that purpose, here are some pointers that you need to take into account:

Here at Forecast 3D, we have a passion for ideas, design, and manufacturing. We are excited to work with your ideas to create a solution for your next project. Whether you need CNC machining, injection molding, stereolithography, selective laser sintering, or hybrid tooling services, we have what it takes to get the job done. We specialize in rapid prototyping, additive machining, and custom...

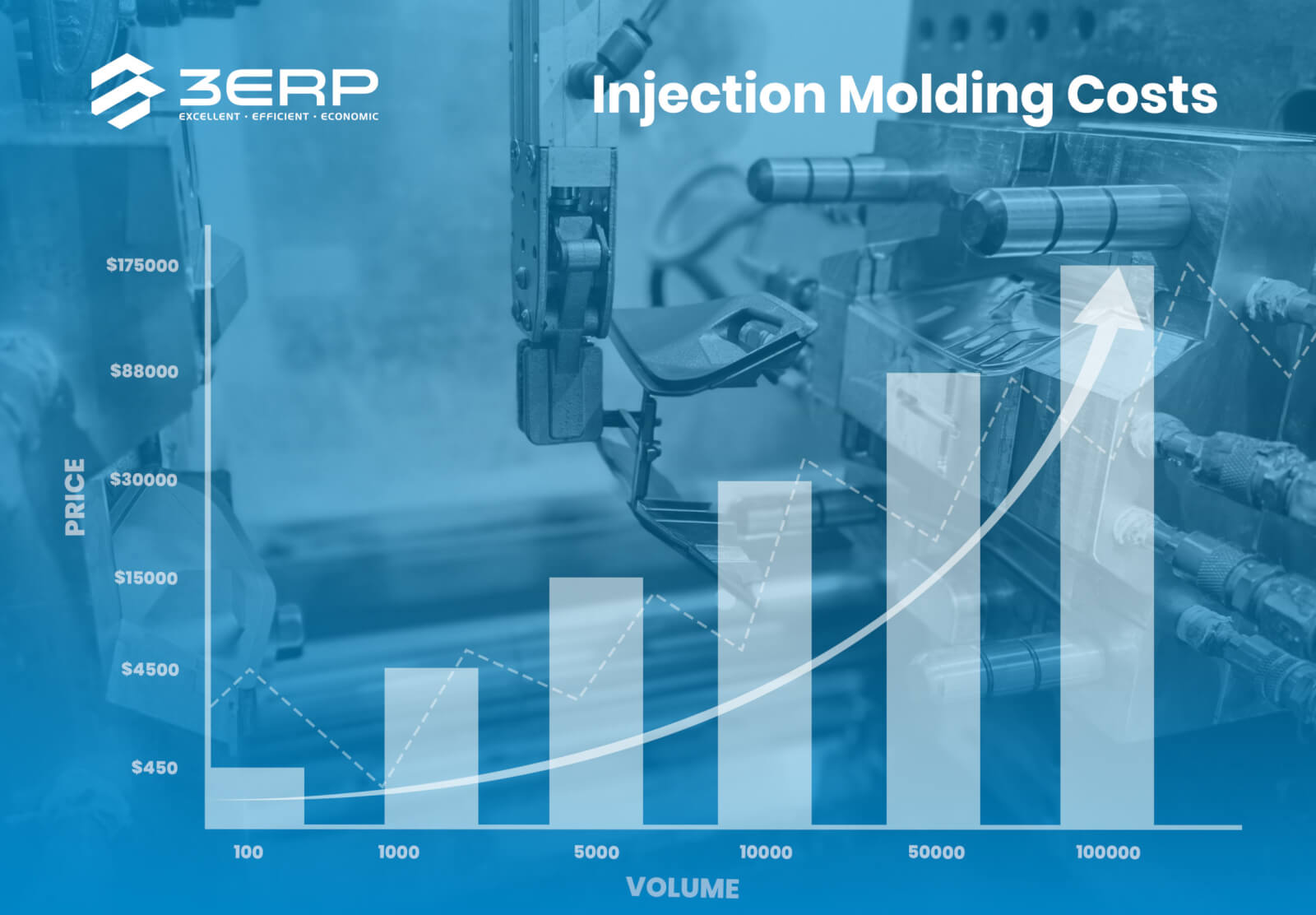

What is the cost of injection molding? This is a commonly asked question by people wondering about adopting this technology.

We are a leading injection molding company at Molding Corporation of America (MCA). With over 50 years of experience in the industry, we have established ourselves as a trusted partner for customers seeking high-quality custom plastic injection molding solutions. Our state-of-the-art facilities, advanced manufacturing processes, and commitment to innovation and quality have made us a go-to choice ...

Professional industrial injection molding equipment costs between $50,000 and $200,000. There may also be shipping costs involved. These machines are not for hobbyists and amateurs as they require skilled operators.

Single cavity molds have one cavity inside. So they make one part per cycle time. While the cost of the mold is less, the production rate of parts is slower. This leads to higher part costs.

Aprios Custom Manufacturing West is a trusted provider of high-quality injection molded plastics products and comprehensive manufacturing solutions. Located in Vista, CA, we specialize in delivering exceptional products and services to meet the diverse needs of our customers.

Medium volume production can range between five thousand to tens of thousands of parts. For this production scale, manufacturers usually outsource the mold production and molding processes.

This article examines the costs of injection molding. Understanding the factors that influence these costs will help you estimate your injection molding project costs.

While the molding equipment is a one-time investment, creating the mold and mold base for the part costs money. It is an expense for every different part produced. Therefore, tooling costs are one of the most important driving factors for injection molding.

3ERP provides every injection molding service you might require, from low-cost injection molding to mass production parts. There are even material options, such as thermoplastic, thermoset silicone, and metal injection molding.

As a full-service rotational molding company, Roto Dynamics is your source for high quality, custom rotomolded products. Since our inception, we have continued to earn success by closely working with our customers, developing innovative and tailored solutions. We are with you every step of the way, from design and development to production and assembly. For a complete view of our capabilities and ...

Polyurethane molding is the process of fabricating or manufacturing plastic parts by introducing a urethane polymer system into a tool or mold and allowing it to cure. Like any other type of plastic, the excellent processability...

Are you considering using injection molding service for your next project? Then send a query to 3ERP at our contact email, and our team will reach out to you with the best price available for your requirements.

Family injection molds also have multiple cavities inside them. However, the part cavities are for different parts, so a family mold can simultaneously create different shapes of injection molded parts.

Not at all. Injection molding is one of the cheapest manufacturing processes. Even so, you can still lower the injection molding costs per molding cycle by following the tips suggested in this guide.

Highly complex designs with more cavities and high mold polish result in extra costs. Such designs require research, development, and technical expertise. For this purpose, you can hire a professional or outsource the design process. Both options incur expenses.

For low production quantities, manufacturers create molds of 3D printed polymer resin since it is cheap and doesn’t have to go through a long production cycle.

C.F. Maier Composites is a fiberglass fabricator providing fiber-reinforced products. Our fiberglass fabrications and fiberglass products are used in a number of applications, including bathroom tubs and showers, tanks, boats, roofs, vehicle components, ducts and pools, as well as many other applications.

This is a very wide price bracket. The exact value fluctuates based on several components involved in the injection molding process. These factors that influence the cost are:

Now that you know the various costs associated with injection molding, one vital question remains unanswered. What will be the cost of injection molding for my project?

At FABEXCO, we specialize in plastic extrusions. Our passion lies in crafting profiles that set us apart from the competition. We relish challenges and thrive on projects with unique specifications, tight deadlines, and unconventional requirements. Our commitment to excellence drives us to deliver results that others simply can't match.

Aprios Custom Manufacturing West is a trusted provider of high-quality injection molded plastics products and comprehensive manufacturing solutions. Located in Vista, CA, we specialize in delivering exceptional products and services to meet the diverse needs of our customers.At Aprios Custom Manufacturing West, we offer a wide range of injection molded plastic products designed to... $$$

After reading this guide, you can evaluate the exact manufacturing costs that injection molding will require for your particular requirements.

This is a little more complex process than basic injection molding. It involves positioning metal inserts in the mold. Once the metal inserts are in position, the plastic injection molding takes place.

Electrical Discharge Machining is also known as EDM. This technology is utilized for creating molds with intricate shapes. It is accomplished by using electrical discharges to melt and bend the metal workpiece and give it the desired shape.

Acorn-Gencon Plastics offers a full line of injection molded plastic products and services. With 27 injection molding presses, from 55 to 650 tons, we have the manufacturing capabilities to satisfy all your requirements, and our experienced engineering staff ensure product quality, manufacturing efficiency, and cost-effectiveness. From concept to completion, we can assist you with every step of...

An example of this is the soft rubber grip that you see embedded into plastic and rubber products, such as toothbrushes.

Multi cavity molds have multiple cavities inside, so they can make more than one part simultaneously. Although this type of mold has a higher initial cost, it leads to significantly lower part costs. It is a cost-effective solution for large quantities.

The benefit of self-mating parts is that you can use a single half mold to create the entire part. It keeps the cost of the mold low, and the plastic injection mold size is half. This method increases the volume of production.

DFM stands for Design For Manufacturing. DFM in injection molding refers to producing a part that serves the purpose of the customer and is within their stipulated budget.

If you want high quality plastic molding products, you’ve come to the right place! We are a large supplier of a variety of molded plastic parts of all sizes and types. We have the inexpensive solution to your needs that can get the job done right the first time. You will find that our attention to detail sets us apart from the competition. Give us a call or visit our website today for more info!

Just like CNC machining, EDM also has high accuracy. However, while CNC machining can be used for materials other than metals, EDM is only suitable for metal molds.

Plastic injection molding, or commonly referred to as injection molding, is a manufacturing process used in the mass fabrication of plastic parts. It involves an injection of molten plastic material into the mold where it cools and...

Plastic fabrication is the process of designing, manufacturing, and assembling a product made out of plastic material or composites that contain plastic. There are numerous plastic fabrication methods known today, considering the...

The injection mold cost of 3ERP will come as an exact quote that matches your precise requirements. Therefore, you will not be paying extra for something you do not require.

Since its founding in 1992, American Grating has manufactured top quality molded and pultruded fiberglass gratings, pultruded structural profiles, handrail and ladder systems, and hand lay up custom components. In 1999, AGL achieved ISO 9002 certification and in 2000 achieved ISO 9001 certification which provides international guidelines on quality management and quality system elements. American ...

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

We, as representatives of LTM Plastics, are proud to introduce our company, which has been specializing in injection molded plastics since our founding in 1977. Over the years, we have developed a strong reputation for delivering high-quality products and excellent customer service.At LTM Plastics, we offer a wide range of injection molded plastic products, including parts for the... $$$

At SDM Plastics, Inc, we take immense pride in our role as a reputable provider of injection molded plastics products and services, firmly rooted in the city of Corona, CA. Our unwavering commitment to excellence, innovation, and, most crucially, customer satisfaction, forms the cornerstone of our operations. We specialize in offering a wide array of products and capabilities, all meticulously ... $$$

FRP Resource is one of the largest manufacturers of fiberglass gratings (molded and pultruded) with guranteed quality and the lowest price. We also offer quality glass fiber products (i.e. Gun Roving, Woven Roving) and steel grating molds. For more info, see our website!

Since 1974 we have been a well-established plastic molding company at Medway Plastics. Besides custom injection molding, we provide various value-added capabilities such as process capabilities, material specialties, research & development, and engineering & design. We are committed to providing high-quality products and exceptional customer service. No matter the complexity of your needs, we...

After reading this article, you now have a better idea about the plastic injection molding cost and how it varies from project to project. You even know about the cost variations that occur due to the injection mold cost and injection mold tooling cost.

If the manufacturer needs additional services such as polishing or secondary finishing for the product, these represent an extra expense. While it is not a part of the injection molding cost, the service provider might consider it an added cost.

Repair Costs: Injection molding is a mechanical process requiring multiple types of equipment. Therefore, there are bound to be repair and maintenance processes that result in expenses.

Similarly, the labor costs per part also decrease for larger production volumes. While the final cost of production increases for higher production volumes, you will incur significantly lower per part expenses.

The cost of material for plastic resin pellets used in the injection molding process is from $1 per kg to $5 per kg. The final cost of injected material will depend on the amount used, which, in turn depends on the design required.

Here at Kennerley-Spratling, Inc., we have provided reliable service and high quality molded products since 1955. We have experience manufacturing custom plastic components for the medical, electronics, consumer, and many other industries. As an ISO 9001:2008 certified company, meeting your specifications with quality molded solutions is our priority. We even have our own class 100,000 clean room ...

Quality Plastics has been a leading manufacturer of vacuum forming since 1976. We understand the importance of quality and timely delivery, which is why we adhere to strict quality control standards and work diligently to meet our customers' deadlines. Whether you need a small batch of custom vacuum-formed parts or a large-scale production run, we have the capabilities and expertise to deliver....

The best thing is that you get your parts made by a world-class team of engineers using the most advanced equipment, without bearing any of the costs for the same.

This process creates plastic parts with metal inserts fused directly into them. An example of this is the metal fasteners that you see inserted in plastic components.

The base cost of an injection mold is not a fixed number that will be the same for every application. It is a varying value that can fall between a couple of hundred to hundreds of thousands of dollars.

The second process creates Part 2, which contains Part 1. This process is similar to insert molding, with the difference that, instead of a metal insert, both parts are created with plastic injection molding.

The features of the final product also impact the injection mold cost. If the product has complex features, these might require small components made by a separate injection molding process. One way to lower costs is to eliminate unnecessary features during the design stage.

The entire production run for this volume takes about 3 days to manufacture the finished parts. For a 100-part run, let us assume the following parameters:

You might have seen that manufacturing costs per part become less when the production takes place in large quantities. The same idea holds true for injection molding as well.

Low volume production can be considered anything between a hundred to a couple of thousand parts. For these low-volume applications, manufacturers usually produce the molds in-house and do the molding themselves.

Bigger parts are not always better parts. When the size of the parts increases, so does the expense of injection molds required for the parts. If the same process can be accomplished by reducing the part size, it is a good idea to opt for it.

Large volume production deals with hundreds of thousands of parts. For this comparison, let us assume we are producing 100,000 parts of the same type.

Lera Glass is dedicated to the art of craftsmanship collaborating with architects, engineers and designers in the production of quality fiberglass fabrications. Projects range in scope and scale, but always result in high quality fiberglass products and components. Though originally specializing in fiberglass; wood, metal and acrylic fabrications are also available to better serve your needs.

Since our incorporation in 1956, Paramount Fabricators has established itself as a leader in the fiberglass reinforced plastic (FRP) industry. Specializing in the manufacture of FRP process equipment, we have designed and manufactured numerous fiberglass products such as wet scrubbers, carbon odor control units, gas scrubbers, process vessels, duct, pipe, tanks, shipping containers and more.

The process results in a final assembly with greater strength than mechanically fixing the plastic and metal parts together.

In this regard, you can eliminate any features that are just for the sake of cosmetic finishes. This will end up saving money.

Closed cell foam is a type of foam where the “cells” are tightly pressed together and enclosed. It contrasts open cell foam, such as polyurethane, with interconnected open cells. With closed-cell foam, because none of the cells...

We use glass-filled materials as well as engineered and commodity resins. We've made products for various industries—automotive, consumer products, containers, electronics, lawn and garden, outdoor furniture, pharmaceutical and more. We also are ISO 9002 registered—contact us today!

Thermoforming is the process of heating thin plastic sheets to its forming temperature and stretching it over a mold which takes its shape. After cooling and setting of the molded plastic sheet, each part will be separated from its batch to form a single unit or product...

Headquartered in Scottsdale, Arizona, since 1988, Applied Process Equipment, Inc. is a distributor of pumps, tanks and water and wastewater treatment equipment servicing the southwest United States. We offer product and systems sales and design application assistance services to municipal, industrial, commercial and builder/developer clients. We assist design professionals, consulting engineers,...

This is one of the most creative ways to save money on injection molds and simplify the design. Self-mating parts are the parts that attach to themselves when rotated 180 degrees.

Fiberglass molding is a method for forming complex and intricate parts using fiberglass resin. Though there are several reasons for producing parts and components from fiberglass, the most pressing reasons are the...

Plastic injection molding offers a certain degree of versatility concerning the plastics you can use as the injection material. Some examples include ABS, PU, PE, PP, and PC.

At SDM Plastics, Inc, we take immense pride in our role as a reputable provider of injection molded plastics products and services, firmly rooted in the city of Corona, CA. Our unwavering commitment to excellence, innovation, and, most crucially, customer satisfaction, forms the cornerstone of our operations. We specialize in offering a wide array of products and capabilities, all meticulously ...

Established in 1985, CJI Process Systems are leading specialist in the fabrication of a large range of materials including all metal alloys, steel, thermoplastics and fiberglass in addition to manufacturing parts washers like aqueous washers. Offering turnkey solutions for custom tank lines, water evaporators, sandblasting and coating abilities, we deliver finished products that are built to last.

Competitive Engineering is a world leader in the manufacturing industry , and we have a huge selection of services to meet the diverse needs of many industries. We offer engineering, design, precision machining, plastic injection molding, 3D printing, and assembly services. Contact us to discover how we can assist you with your next manufacturing project.

Eagle Mold Technologies specializes in plastic injection mold making for the medical device and electronics industries. We offer insert molds, hot runner, production multi-cavity and quick turnaround aluminum molds.

Every injection molding material has its specific benefits. The perfect material for your injection mold will depend on your requirements and budget constraints.

3D printing is one of the cheapest and fastest ways of making molds for injection molding. This process requires nothing but a 3D printer, so the expense is considerably less. Additionally, there is no need for skilled operators, saving labor costs.

This cost can vary based on the process used to create the molds. Usually, three processes are employed for this purpose:

To get a better understanding of the plastic injection molding costs for a part for different production volumes, let’s examine a typical case.

When you are fulfilling a large production volume, you will require a corresponding large number of molds. However, the cost of the molds does not increase linearly. For example, if the cost of a mold is $1 per part for 100 parts, the cost for 5000 parts can be about $0.5 per part, and for 100,000 molds it can be $0.25 per part.

As stated in the plastic injection molds cost overview, higher volume means lower costs per part. This, combined with savings in mold size and number of molds, lead to significant savings in the final plastic injection mold costs.

As you can see, the injection molding costs per part decrease significantly for high-volume production. Therefore, high-volume projects have the best cost-effectiveness for injection molding costs.

The size and design of the part will considerably affect the cost. Large injection molded parts require greater material costs and larger molds. Similarly, complex designs may require a multi-step molding process.

Specializing in open and closed molding for over 45 years. We are capable of molding complex shapes and assemblies. If you're tired of bad service and marginal quality, we are your solution. We can take you from design to production in the shortest time. Member of the American Composites Manufacturers Association.

Newport Plastics does custom injection molding with a full mold shop and capabilities for small and large runs. Our molded plastic parts are used in the medical, aerospace, consumer goods and telecommunications industries. We offer custom mold design, in-house tooling, design and prototyping and design assistance. With 36 years in the business, you shouldn’t hesitate to call Newport Plastics!

For DFM, analysts consider several factors based on art, science, and technology to find the most efficient design, resulting in reduced injection mold costs.

Make full use of the molds by reusing them for various applications. You can not only use the same mold for the same part but also for similar parts as well. This can be done by making adjustments or mold mods wherever possible.

Use our thorough list of plastic molding manufacturers and suppliers in California to examine and sort top plastic molding manufacturers with previews of ads and detailed descriptions of each product. Any plastic molding manufacturer can provide plastic molding services to meet your company's specific qualifications. An easy connection to reach plastic molding manufacturers through our fast request for quote form is provided as well. This source is right for you whether it's for injection molded plastic, plastic extrusions, plastic blow molding, plastic dip molding, polyurethane molding, rotational molding, vacuum forming, fiberglass fabricators, or any other plastic molding needs.

Generally speaking, to get an injection mold cost quote, you need to choose the manufacturer who can provide you with the best results at the cheapest rates. 3ERP is your answer in this regard.

Operator Costs: Regardless of the self-regulated machinery used, an operator must oversee the process. The cost of the operator is something to factor into the labor costs.

Rotational molding, commonly referred to as "rotomolding", is a plastic casting technique used to produce hollow, seamless, and double-walled parts. It uses a hollow mold tool wherein the thermoplastic powdered resin is heated while being rotated and cooled to solidify...

This is the simplest type of injection molding process. The plastic is injected directly into the mold cavities to create the final piece. Of the three different molding processes, this one has the lowest cost.

Injection molding is one of the most widely applied manufacturing processes nowadays. Every day, you see and touch multiple parts created by this process, like bottle caps and plastic handles.

Founded in 1984, Hi-Rel Plastics & Molding, Inc. is a turn-key manufacturer who offers custom plastic injection molding and custom blow molding for a variety of industries. Our facility enables us to serve every facet of the molding process from part evaluation, 3D Printing, prototyping, tool design, tool making, sampling and production of quality finished plastic and metal parts. With more than...

Most steps involved in injection molding are automated and run by software systems. For instance, CNC machines are run by Computer Numerical Controlled software, 3D printers run on their own software, and injection molding also has automated processing.

Since 1967, Mark Optics has specialized in quality glass fabrication and fused silica substrates. We specialize in precision flat optical components and ultra-thin wafers. Our capabilities include lapping, precision polishing, cnc shaping and much more.

Overmolding is also a little more complex than basic injection molding. In overmolding, an initial part is created using injection molding, let us say Part 1. Then, Part 1 is placed inside another mold, and another plastic injection molding process takes place.

Complex features can call for complex molds and extra steps in the injection molding process. Therefore, eliminating unnecessary features results in a lower cost for injection molds.

We, as representatives of LTM Plastics, are proud to introduce our company, which has been specializing in injection molded plastics since our founding in 1977. Over the years, we have developed a strong reputation for delivering high-quality products and excellent customer service.

Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two dies that contain the desired shape of the product...

For example, you can manufacture the top and bottom ends for a plastic container in a single-family cavity injection mold. This type of mold cavitation is a more expensive option in terms of mold cost. But they make the overall production process faster and cheaper.

Injection molding is a popular manufacturing process for creating many parts and components. As such, learning about the costs of producing an injection molded part is vital before considering this process for your manufacturing operation.

Many established brands such as BMW, Lamborghini, and Electrolux already use the injection molding services offered by 3ERP.

A single part can be approached through different CAD designs. However, not every design idea is ideal. Some designs for the same part may lead to time and resource wastage. Therefore, simplifying part complexity through efficient CAD design ensures the best utilization of resources.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly