Rubber Injection Molding Company - rubber plastic molding

Author:gly Date: 2024-10-15

Each development project requiring Polycarbonate molding services is managed by a Project Engineer who monitors and controls deliverables and provides regular status updates.

Our polycarbonate molding assembly and joining capabilities include product filling, foil/heat sealing, ultrasonic welding, heat staking, mechanical assembly, pinning & UV/hot melt gluing, custom packaging/kitting, and pouching.

For the consumer polycarbonate molding market we specialize in the automated production of high-volume disposables, unit-dose packaging, caps and closures, and over-the counter diagnostics and drug delivery applications.

Our polycarbonate molding product finishing capabilities include hot stamping, banding, pad printing, silk screening, flaw coating, conductive painting, cosmetic painting, metalizing, and plating.

We are an ISO-certified, family-owned provider of engineering, custom injection molding, and contract manufacturing. Our clients bring demanding applications requiring Polycarbonate molding services and best served by expert engineers.

In the electronics market, including polycarbonate molding, we draw upon deep experience in comprehensive analysis and testing for evaluation and verification to design and build lighter, more durable electronics components.

Natech’s projects that include Polycarbonate molding services are supported by MoldFlow Analysis, a Viscosity Curve, a Cavity Balance Study, a Pressure Window Characterization, a Gate Seal Time Study, and a Cooling Time Study. Natech engineers are masters of insert configuration and design single-cavity R&D molds with steel inserted areas. Interchangeable plates, inserts, and sub-inserts allow for more rapid design iterations at LOWER cost than creating new molds for each feature variation. SPI Class 103 and 104 molds are constructed from P20 steel and aluminum with hot runners and cold runners.

We have developed hundreds of products, some with polycarbonate molding, and manufactured millions of parts annually for the medical industry. Medical devices include point of care diagnostics, microfluidics, and pharmaceutical drug delivery applications.

Fresno’s plastic injection molding companies boast a wealth of expertise, with seasoned professionals dedicated to maintaining high standards of quality and precision. Skilled engineers and technicians oversee the manufacturing process, ensuring that every mold meets rigorous quality benchmarks. With on-site support readily available, businesses can trust in the expertise and capabilities of their local manufacturing partners.

Our mold maintenance plans for projects that include Polycarbonate molding services ensure each mold undergoes regular cleaning and review at predefined intervals based upon the number of setups and cycles. Mold inspections, general mold maintenance, major mold maintenance and preventative maintenance are standard operating procedures.

Our mid to high-volume polycarbonate molding automated and semi-automated manufacturing of plastic injection-molded components and assemblies for single-use, metered-dose, and multi-use disposables for the drug delivery, consumer packaging and diagnostics industries offer high quality at economical value.

In today’s dynamic business landscape, selecting the right plastic injection molding partner can significantly impact a company’s success. Fresno, California, serves as a thriving hub for plastic manufacturing, offering a range of advantages for businesses seeking reliable solutions. Here’s why collaborating with a local plastic injection molding company in Fresno like Jet Mold Products Inc. can streamline operations, ensure quality, and foster long-term success.

Collaborating with a local plastic injection molding company fosters community support and collaboration, contributing to the economic growth and prosperity of the region. Building long-term relationships based on trust and mutual respect enhances innovation and continuous improvement efforts. By investing in local businesses, companies play an active role in supporting the local economy and fostering a sense of community.

Opting for a local plastic injection molding company means enjoying convenient proximity and accessibility. Fresno’s strategic location, with its connectivity to major transportation networks, facilitates quicker communication and transportation of goods. This closeness translates into reduced lead times, ensuring timely production schedules and enhanced operational efficiency.

Local plastic injection molding companies in Fresno prioritize customization and flexibility, working closely with clients to understand their unique requirements. Whether it’s adapting existing molds or creating new designs, these manufacturers offer tailored solutions that meet specific needs. This collaborative approach results in molds that fit precisely and ultimately deliver superior final products.

The production molds for Polycarbonate molding projects include high cavitation SPI Class 101 and 102 molds constructed from hardened steel. Cold, runner, hot sprue, and hot runner molds are designed with up to 128 cavities.

Partnering with a local plastic injection molding company in Fresno contributes to sustainability efforts by minimizing transportation distances and reducing carbon emissions. Many Fresno-based manufacturers embrace eco-friendly practices, such as utilizing recycled materials and implementing energy-efficient processes. By aligning with these environmentally conscious partners, businesses can support sustainability initiatives and reduce their environmental footprint.

Clients trust Natech to be the Polycarbonate molding experts in engineering and manufacturing. Our engineers’ experience includes mold qualifications in medical IQ/OQ/PQ, high volume automation in consumer packaging, and engineering-grade resins and ultra-polymers in electronics.

We provide Polycarbonate molding services in New York, New Jersey, Connecticut, Pennsylvania, Florida, California, Illinois, Oregon, Maryland, Massachusetts, Colorado, and Michigan and other regions.

We take pride in the workmanship of our Polycarbonate molding services. All Natech tools and production parts are made in the USA. We run three shifts per day, five days per week, and weekends are run on an as-needed basis.

Serving: Fresno, Visalia, San Luis Obispo, Santa Barbara, Merced, Madera, Modesto, Stockton Sacramento and Nationwide businesses.

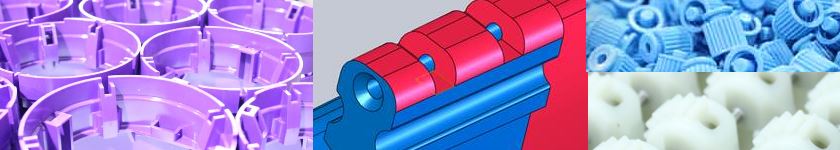

Our precision injection molding options include scientific molding, R&D molding, high-cavitation molding, micro molding, over molding, and insert molding.

In conclusion, partnering with a local plastic injection molding company in Fresno offers numerous benefits for businesses seeking reliable manufacturing solutions. From convenience and customization to quality assurance and sustainability, Fresno’s local industry provides a range of advantages that can drive operational efficiency and long-term success. By embracing local partnerships, businesses not only strengthen their supply chains but also contribute to the prosperity of the community, positioning themselves for sustained competitiveness in the market.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly