Pricing Guide: China Injection Molding Cost - custom plastic molding cost

Author:gly Date: 2024-10-15

The construction industry requires lighter-weight components, the ability to recycle materials, shorter production times, and lower labor costs. Milacron technologies help meet these goals.

While the two-shot molding method may seem more complicated and time-consuming than traditional injection molding, the reality is that from start to finish, it offers several advantages when you need something that is more assembled or consists of multiple components or materials. Benefits include:

We are committed to positively impacting the environments in which we operate through our people, products, and partnerships.

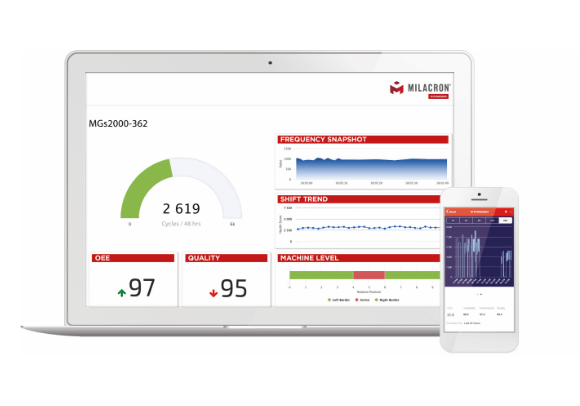

Our IIoT platform designed specifically for plastic production. M-Powered is a portfolio of easy-to-use observational, analytical, and support services that gives customers a competitive advantage.

With over 50 years of industry experience, Milacron offers customers more than machines. We are a complete lifecycle partner here to help you develop sustainable manufacturing processes, optimize existing production, and decrease downtime. Our team can design completely new processes from the ground up or help streamline existing processes to meet your business needs. With process consultation and fleet audits to advanced technologies and machine upgrades, we are dedicated to keeping you on the cutting edge of plastic processing technology.

Milacron technologies manufacture a vast array of automotive parts, both large and small, with a focus on keeping parts durable, lightweight, and fuel efficient.

Our technologies help create items that make daily life easier for consumers. We enable you to bring products to the market quickly and affordably, with a keen eye to sustainability.

When two materials are joined, there’s often trimming and scrap, but when they are molded together, we can minimize the waste and reduce the materials used. Again, this lowers costs, but it also improves the sustainability of the product.

Milacron’s latest technologies in rapid product development cycles meet the demand for superior part quality, precision, and ever-smaller components at lower costs.

The process begins similarly to traditional injection molding in which the liquid polymer is injected into a mold and is then cooled, but before it is a solid. Next, the component is robotically or automatically transferred into a new mold where the second material, color, or texture is added, and as it cools, it forms a molecular bond to the first material. The end result is a more completed, highly durable component, part, or product.

We help our customers create innovative and unique packaging that is attractive and functional. Milacron technologies offer cost-effective solutions that help you stand out from your competitors.

From clear-room systems to high-precision machinery, Milacron's plastic processing solutions help produce new medical technologies and generate advances in the high-demand medical industry.

Since 1988, Advanced Plastiform, Inc., has been providing superior custom plastic molding and fabrication services to companies in North Carolina, South Carolina, Maryland, Georgia and Pennsylvania. Contact us to make an appointment Mon-Fri 8-5.

Also called double injection molding, this is a method of manufacture where the goal is to form a part or a product made from two different materials or the same materials with different texture or color in one step, rather than forming them separately and fusing them together.

If your product design requires complicated components and mixed materials, you may be concerned about the multi-step manufacturing and assembly, not only the costs and time involved, but also whether the materials will bond properly and create a long-lasting result. The more steps required, the more time it takes and the more it costs, but with two-shot injection molding, this can streamline manufacturing and improve the results. To help you better understand this method of manufacturing plastics, our injection molding company in North Carolina is taking a closer look at two-shot injection molding.

Through transparency and accountability, we will shape a sustainable world while driving results across the organization.

You won’t need a more complex mold for the process, and because the parts are manufactured all-in-one, there is no need to weld or join components together. This saves time and minimizes labor, which will save money on overall manufacturing costs.

The industrial internet of things (IIoT) networks your machines and collects valuable data about your manufacturing process. By leveraging this data, you can increase productivity, efficiency, and your bottom line.

By saving time, minimizing costs, and reducing the steps involved in going from start to finish, you can get your product on the shelves or finish the overall project more quickly. Efficiency in manufacturing leads to overall improvements in operation and reduced costs.

Since 1988, Advanced Plastiform, Inc. has been a leading plastics manufacturer in the Southeast and Mid-Atlantic, using thermoforming and injection molding to design and create durable, high-quality products at a low per-unit cost and fast lead time. To learn more about how we can help you reduce your costs and improve your quality, schedule a quote. We work with all types of industries in North Carolina, South Carolina, Pennsylvania, Maryland, Tennessee, Georgia, and Virginia.

Double shot injection molding is used in a wide variety of applications. In automotive injection molding, one example is molded-in buttons on a steering wheel that are a softer texture than the rest of the wheel. In medical injection molding, you’ll see that dental mouth guards are often made through double molding where the “frame” is a harder plastic while the bite area is softer.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly