Polystyrene Injection Molding | PS Plastic - hips injection molding

Author:gly Date: 2024-10-15

To make a well-informed decision, it’s important to also consider what may make the injection molding processes less desirable.

At SMC we understand that precision matters when it comes to micro molded medical parts. We manufacture even the smallest parts while still holding precise tolerances.

Two-shot injection molding and overmolding are versatile solutions. But, what makes one more practical than the other for a specific application?

The newly molded substrate is then transferred either robotically, manually, or via an automated rotary plane to a different cavity within the same tool. In the second phase, the substrate rotates 180 degrees in the tool. Another resin is then injected to surround and molecularly bond to it. Once cooled, the final part is ejected.

Overmolding is an ideal solution for commercial and industrial applications such as soft-grip handles on razors, toothbrushes, and handheld tools. In medical and automotive applications, overmolding may be used to decrease vibration, insulate sound, and improve chemical resistance.

Two-shot injection molding (or, two-stage molding) and overmolding are popular choices for many applications. They are also often mistaken as being interchangeable.

SMC's micro molding capabilities yield 10,000 parts per pound of resin. Micro parts are considered less than 0.003 cubic inches and fall between 0.140 x 0.140 x 0.155 inches.

Copyright ©2023 SMC Ltd. All rights reserved. SMC and the SMC logo are registered trademarks of SMC Ltd. Privacy and Cookie Policy UnitedHealthcare’s Transparency in Coverage

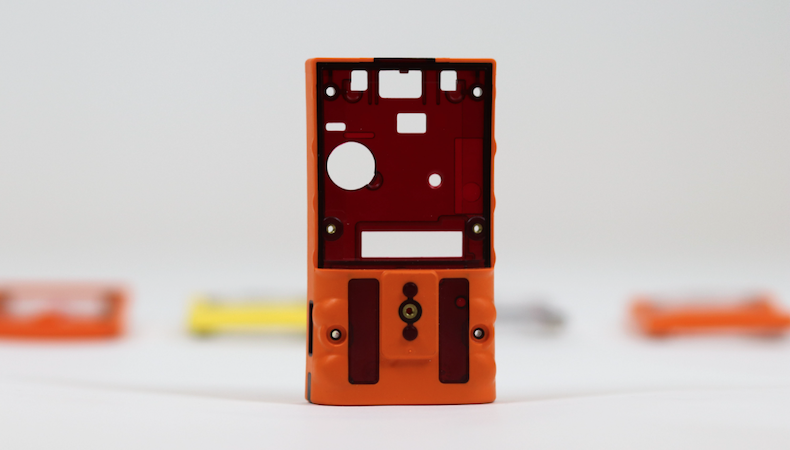

Overmolding is a multi-shot process, involving two separate molding operations and two separate tools. It combines a rigid substrate base with a pliable outer layer of plastic such as thermoplastic elastomer (TPE) or liquid silicone rubber (LSR). The substrate base is formed by injecting resin into a tool, where it cools and solidifies before being moved to an overmold cavity within a different tool.

The more knowledge you have, the better prepared you will be to make the best choice. Before making injection molding decisions on current or future projects, get up to speed on Overmolding Fundamentals for OEMs. Click the button below to download your copy of this valuable white paper.

True micro-molded parts can be smaller than the pellet of resin used, allowing multiple parts to be made from one resin pellet. Our efficient material and tooling techniques deliver exceptional yields of 10,000 parts per pound, including the runner. While miniature parts are the next step larger in physical size, they often have micro features. Knowing how to inspect and package micro and miniature components, assures parts to specification from the molding operation to the end device.

While they share several similar production steps, there are key differences in the techniques. It is these dissimilarities that help determine which process is best suited for a specific application.

Typically, two-shot injection molding is used for complex applications that may require multiple materials or multiple colors. Interior parts in vehicles, appliances and housewares, and device panel push buttons or handle grips exemplify common applications for this process.

To provide context for an accurate comparison of two-shot injection molding and overmolding, a brief overview of each process is necessary:

Two-shot molding consists of two phases (or shots of material) in one injection molding operation. The first phase resembles traditional injection molding. Resin is flowed into one cavity of the tool, and allowed to solidify and cool in order that the substrate holds the proper shape.

With minor design modifications, injection-molded plastic parts can likely be made using either two-shot or overmolding processes. However, the approach to determining which technique is most appropriate for your application shouldn’t be taken lightly.

In the overmold cavity a second molten material — known as the overmold — is injected around the substrate base. The two layers bond either mechanically or chemically to form the final product.

Injection-molded parts are integral to the performance and aesthetics of a wide range of products. Manufacturers depend on the expertise of their injection molding partner to guide decisions and processes that lead to desired outcomes.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly