Murray Plastics: Custom Plastic Injection Molding Company - us injection molding

Author:gly Date: 2024-10-15

As we mentioned above, each mold polishing method has its advantages and suitability for specific mold materials, shapes, and desired finishes. It is important to choose the appropriate method. What factors should be considered when we make the selection? Here are some suggestions.

Fluid polishing, also known as abrasive flow machining, involves the use of a viscous abrasive media that is forced through the mold cavities and cores under pressure. The abrasive particles in the fluid flow help remove imperfections and polish the mold surfaces. This method is suitable for achieving consistent and uniform polishing on complex mold geometries.

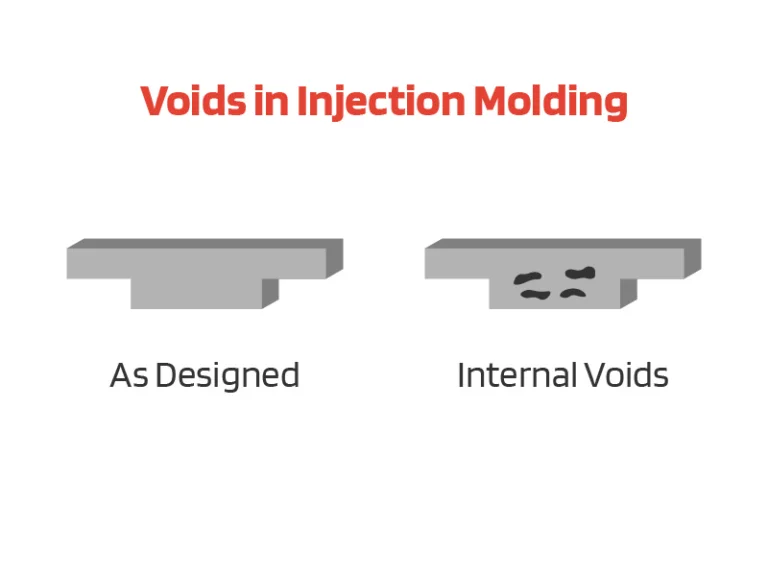

Proper mold polishing helps minimize defects in the injection-molded parts. By eliminating surface imperfections, such as tool marks, scratches, or rough textures, mold polishing reduces the occurrence of defects like flow lines, sink marks, and part sticking. The smoother mold surfaces allow for better resin flow and cooling, reducing the risk of filling inconsistencies and promoting uniform part properties.

Electrolytic polishing uses an electrochemical process to remove surface imperfections. The mold is immersed in an electrolyte solution, and an electric current is applied to selectively dissolve the high spots and rough areas. This method is suitable for complex mold shapes and provides precise control over the polishing process.

Guiding customers through every stage of a custom precision molding project, our comprehensive approach includes advanced design and engineering assistance, mold making, prototyping, real-world testing and automated assembly services.

Whether you’re using custom plastic injection molding to manufacture medical devices more efficiently, to prevent contamination of apparel products, or to reduce the weight of car parts and components, Sonoco has the experience, expertise, and craftsmanship to ensure the success of your project.

Evaluate the complexity of the mold design, including intricate details, thin walls, and complex geometries. Some polishing methods may be better suited for reaching difficult-to-access areas or polishing intricate features.

Have you ever noticed a whitening phenomenon in PVC product whitening? Some of your transparent PVC products, like shower curtains

Consider the type of material used for the mold, such as steel, aluminum, or plastic. Different materials may require specific polishing methods to achieve the desired finish without causing damage.

Injection mold polishing refers to the process of refining and smoothing the surfaces of the mold cavity and core used in injection molding. It involves the removal of imperfections, such as tool marks, scratches, and rough textures, to achieve a high-quality and mirror-like finish on the mold surfaces. The goal of mold polishing is to ensure that the molds produce parts with precise dimensions, excellent surface quality, and minimal defects. Click here to learn what is mold cavity and core.

It is often beneficial to consult with experienced mold polishers or mold manufacturers to determine the most suitable polishing method for your specific requirements. They can provide insights based on their expertise and help you achieve the desired surface finish while considering practical considerations.

Chemical polishing involves the use of chemical agents or solutions to dissolve a thin layer of the mold surface, resulting in a smoother finish. The chemicals used can vary depending on the type of mold material. This method is effective for achieving a high level of surface smoothness and can be combined with mechanical polishing for optimal results.

This method involves the use of mechanical tools, such as abrasive stones, sandpaper, polishing compounds, and buffing wheels, to manually polish the mold surfaces. It requires skilled operators who carefully remove imperfections and achieve the desired smoothness and finish.

The injection mold structure and design directly influence various aspects of the final product, including its dimensional accuracy, surface finish,

Mold polishing significantly enhances the surface finish of the mold cavity and core, which translates to superior part quality. The smooth and polished mold surfaces help achieve precise and consistent part dimensions, minimizing variations and ensuring the accurate reproduction of intricate details. This results in high-quality molded parts with excellent aesthetics and improved functionality.

Injection mold polishing plays a crucial role in the manufacturing process of plastic components. It is a technique used to enhance the surface finish and overall quality of injection molds, ensuring precise and flawless production. By carefully refining the mold surfaces, polishing helps achieve optimal part performance and aesthetics. In this post, we will explore the world of injection mold polishing, its importance, and the different methods used. Understanding the significance of mold polishing and the techniques available will enable manufacturers to achieve superior results in their injection molding processes.

Consider the project timeline and available resources. Some polishing methods may require more time and labor-intensive processes, while others offer quicker results. Balance the need for speed with the desired level of quality.

Evaluate the cost-effectiveness of different polishing methods. Some techniques, such as ultrasonic or electrolytic polishing, may involve higher equipment and material costs. Assess the budget and weigh the benefits of each method against the associated expenses.

Injection molding flow marks are a common injection molding defect. While flow marks generally do not influence the structural integrity

Mold polishing plays a crucial role in the injection molding process due to its numerous benefits and contributions to part quality and performance. By investing in proper mold polishing techniques, manufacturers can achieve high-quality injection-molded parts that meet the highest standards of performance, aesthetics, and functionality.

Sonoco provides custom injection molding services to make plastic parts and components for virtually any product application across a range of industries. Businesses who demand the best use our custom injection-molded plastics in a wide variety of products, from surgical-grade medical devices to highly technical automotive components.

Mold polishing contributes to achieving consistent part dimensions and improved dimensional accuracy. The removal of imperfections and the creation of smooth mold surfaces help maintain uniform resin flow and cooling during the injection molding process. This minimizes variations in part dimensions and ensures that each molded part meets the required specifications and tolerances.

At Sonoco, we believe in harnessing the power of process to drive innovation. Our proprietary i6 Innovation Process leverages market insights with advanced technical expertise to fully imagine, test, produce and deliver 360-degree solutions. While innovation demands creativity, free-thinking and imagination, the i6 Innovation process gives it direction, power and purpose. Adhering to this disciplined approach is vital to helping solve problems and consistently deliver repeatable, scalable custom plastic injection molding services for our customers.

Mold polishing significantly enhances the visual appeal of the injection-molded parts. The mirror-like finish achieved through polishing gives the parts a professional and premium look. This is particularly crucial for applications where aesthetics are important, such as consumer products, automotive components, and medical devices. A well-polished mold ensures that the final parts have a smooth, glossy surface without blemishes or surface imperfections.

Magnetic polishing utilizes a mixture of abrasive particles and a magnetic field to polish the mold surfaces. The mold is placed in a container with the abrasive media, and the magnetic field induces movement and agitation of the particles against the mold surface, resulting in polishing and smoothing.

Explore the world of mold surface texture in injection molding, where the visual and tactile qualities of a part are meticulously crafted. This post explores the standard of surface texture. Discover how to choose a suitable injection molding surface finish and the common methods for applying textures to injection molding tools. delve into the art

Ultrasonic polishing utilizes high-frequency vibrations combined with abrasive particles to remove surface imperfections. It is particularly effective for polishing intricate and hard-to-reach areas of the mold. The ultrasonic energy enhances the polishing action and allows for better control and precision.

The polishing process typically involves using a series of abrasive materials, such as sandpaper, polishing compounds, and buffing wheels, along with various techniques and equipment. Skilled technicians carefully work on the mold surfaces, gradually removing imperfections and achieving the desired level of smoothness and shine.

In conclusion, mold polishing plays a vital role in the injection molding process. Enhancing the appearance, functionality, and dimensional accuracy of molded parts, ensures high-quality results and customer satisfaction. The various types of mold polishing methods offer different advantages and characteristics, making it crucial to choose the most suitable approach for each specific application. Considering factors such as part complexity, surface finish requirements, production volume, and cost will help in selecting the appropriate mold polishing method. By prioritizing mold polishing and incorporating it into the injection molding workflow, manufacturers can achieve exceptional part quality and maximize the potential of their molds.

Mold polishing is essential in injection molding as it directly impacts the quality and appearance of the final plastic parts. Properly polished molds help prevent issues like flash, part sticking, and uneven filling, resulting in improved part accuracy, reduced production waste, and enhanced overall part performance.

Determine the desired surface finish for the molded parts. If a high-gloss, mirror-like finish is required, a combination of mechanical and chemical polishing methods may be appropriate. For less critical applications, a simpler polishing method may be sufficient.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly