Lightweight, thermally insulating, and low dielectric ... - hips injection moldi

Author:gly Date: 2024-10-15

Acrylics demonstrate excellent scratch resistance. In addition, they can be processed toward featuring a glossy lustrous finish. These properties, combined with PMMA’s dimensional stability, enable its use in many different applications, such as automotive body parts, furniture, or kitchen. Additionally, acrylics are more scratch-resistant than any other glass product. In this manner, the molding process generates products that can maintain their lustrous appearances for a long time without degradation.

PMMA has unique properties for the construction industry such as optical clarity and UV resistance. It is an ideal material for construction applications such as sound barriers, facades, aquaria, and greenhouses. PMMA also has high mechanical resistance and its reliability enables architects to build beautiful architectural monuments.

The office address of LS machinery (Wuxi) Co., Ltd. is No. 102, Xinmei Road, national high salary technology industry development zone, Wuxi City, Jiangsu Province,

PMMA is commonly known as acrylics. Some of its common trade names are Crylux, Plexiglas, Acrylite, Lucite, Perclax, and Perspex. PMMA sheets that are of the glass type are called Plexiglass. It is also used in high-end applications such as hip replacement and lenses for eyewear.

PMMA exhibits excellent optical clarity, high light transmittance property, surface hardness, and scratch resistance which are important properties for electronics that would be used on a regular basis. Due to these properties, acrylics are widely applied to manufacture LCD screens, TV, and mobile phones.

The cooling rate of acrylics is fast thus, the plastic parts are easily stressed. The high and low control of injection mold temperature should be strictly maintained to avoid this. The general injection mold temperature should be controlled at 40-80℃ / 104 – 176°F.

This article is misleading. These are not the world's best as you have only listed companies that have manufacturing in the Far East. Why for instance is Arburg and many other European manufacturers not on this list?

the Shibaura Machine Group was founded in 1949. From April 1, 2020, our company name changed from “Toshiba Machine Co., Ltd.” to “Shibaura Machine Co., Ltd.”

How about Fuhrung servo injection molding machines? Can it be listed into Top 10 injection molding machines manufacturers in China?

1907, Founded by Hokkaido Colliery Steamship Company and the British firms Sir W.G. Armstrong, Whitworth & Co., Ltd. and Vickers Sons and Maxim, Ltd. The headquarters and factory are located in Muroran, Hokkaido.1990, JSW Plastics Machinery, Inc. is established in the United States.

KraussMaffei Company Limited (KMCL) is a subsidiary of ChemChina - the largest chemical company in China and a Fortune 500 company in the world. It incorporates KraussMaffei Group. TianHua Chemistry Machinery and Automation Research Institute Co. Ltd and Fujian Tianhua Intelligent Equipment Co.,Ltd, Combining cutting-edge technology and heritage expertise in product design, development, manufacturing, sales and service.

Photovoltaic modules of solar panels are continually exposed to harsh environmental extremes such as sunrays and rain. Thus, the solar panels undergo constant stress which is why acrylics are a popular choice for photovoltaic solar modules. PMMA is durable, can withstand stress, and is weather-resistant which is why it is the perfect economical choice for solar applications.

From its inception in 1956, when company founder Dr. Seiuemon Inaba first pioneered the concept of numerical control (NC), FANUC has been at the forefront of a worldwide manufacturing revolution.

Injection molding machine, die casting machine, plastic extruder, machine tool, ultra precision machining machine, micro pattern imprinting machine, glass component forming device, industrial robot, electronic control, casting

Woojin Selex is manufacturer of plastic injection molding machine which is producing the high quality plastic material for cellular phone, semi-conductor and other engineering plastic products. Woojin Selex has developed variable models from " Selex-NE series" as a first runner in Korea to the economic class "Selex-ND series" .

Acrylics are more flexible, lighter in weight, and exhibit more impact resistance than glass. They are easier to mold and fabricate according to the design specification. Additionally, Acrylics exhibit better insulation properties than glass which makes them perfect for skylights.

The thermal stability of PMMA injection molding is medium and the thermal decomposition temperature is slightly higher than 270℃ / 518°F. For screw-type injection molding machines, the barrel temperature should be controlled at 180 – 230℃/ 356 – 446°F.

We started business as a machine tool manufacturer in 1938 under the Shibaura name, and our Shibaura brand, which we continue to use, is still widely recognized around the world, especially in the machine tool industry.

Standardization and quality are part of our companies core values. We deliver the best possible experience and product to our customers, every single time consistent. Take a look at our certificates!

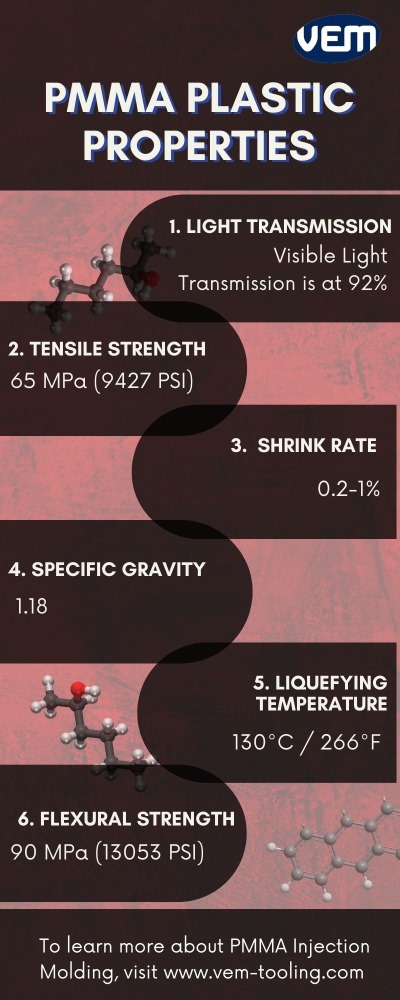

Acrylic has a density of 1.185 g/m3 – 0.00185kg/m3 whereas glass has a density of 2.4 g/m3 – 0.0024kg/m3 thus, PMMA plastic molding produces lightweight products and is an excellent alternative to glass.

As injection molding developed and became more integral to manufacturing, PMMA became even more versatile and the ‘plastic of choice’ for various manufacturers! Today PMMA gets injection molded into countless products.

The Chen Hsong Group was established by Dr. Chen Chiang in 1958. Chen Hsong produces around 15,000 machines annually, approximately 1 machine sold in every 10 minutes, with a customer base covering more than 90 countries worldwide, including China, Taiwan, U.S.A., Canada, France, U.K., Germany, Turkey, India, Brazil, Argentina, Mexico and most S.E. Asian countries. Clamping force starts from 20 tons to 6,500 tons, with shot weight from 28g to 110kg.

Acrylics have a water absorption rate of 0.3-0.4%. For injection molding, it should be below 0.1% of the temperature i.e. usually 0.04%. The presence of water leads to air bubbles and the formation of airlines thus, PMMA resins need to be dried well before introducing them into the barrel.

Cast Acrylics are produced by mixing acrylic liquid ingredients in molds. During the production process, the liquid ingredients are pumped into a mold which is then submerged in warm water, and here, the polymerization takes place. Some of its properties are listed below:

Acrylics are inherently stable to UV light which is why PMMA is used for many outdoor applications such as solar panels.

PMMA is considered to be a better alternative to Glass. Glass is generally expensive, heavy, and can be unwieldy. E.g. iPhone screens are usually Gorilla glass and they are thus, heavy-weighted and expensive whereas various other brands use acrylic plastic for the screen displays thus, making the phones lightweight and relatively cheaper.

Since the viscosity of PMMA melt is high and the flowability is poor, the injection pressure should be maintained high at 80-120 MPa / 11603-17404 Psi. The holding pressure is 40-60MPa / 5801-8702 Psi.

I will tell you not today, it will be in future. Regarding quality, it can be top 10 injection molding machines manufacturers in China.

PMMA beads or pellets which are usually the starting material should be free of solvents to avoid the formation of bubbles. This is achieved by drying. PMMA Injection molding is the same process as conventional injection molding:

If you think some injection molding machines manufacturers should be listed TOP 10 also , write to us. We will add them into this list.

Acrylic is one of those rare plastics that combine high-performing characteristics with beautiful aesthetics. The aesthetics can be customized according to the designers in the form of color, finishes, and effects. In addition to the furniture and design industry, acrylics are a popular plastic of choice for manufacturing photo frames, clear table tops, and storage plastic parts.

Acrylics can be mixed with resins to create a wide variety of colored products. It can be further modified to improve a specific property. This is generally achieved by incorporating additives. These modifications are typically performed

Since 1953, Husky has grown to become a global leader in injection molding systems and services to the plastics industry, with over 4,300 employees in 35 locations worldwide, supporting our customers in over 140 countries. Husky’s headquarters and main manufacturing facilities are located in Canada, with additional manufacturing facilities in the U.S., Luxembourg, Switzerland, China and the Czech Republic. Plus, three technical centers in Japan, Luxembourg and Shanghai.Husky builds, installs and supports the world’s most comprehensive range of injection molding systems and equipment, including machines, molds, hot runners, auxiliaries and integrated systems.

PMMA was first discovered by a German chemist named Otto Rohm in 1901. The PMMA discovered in 1901 was in its most novice and preliminary form and it could not be used for commercial purposes as we use it today. It thus later underwent various developments and by 1943, a more processible form of the PMMA version was developed which created a version of PMMA that can be cured at room temperature.

PMMA provides excellent optical clarity, light transmission, and color accuracy which is why it is extensively used in exterior, rear, and indicator light covers of the automotive.

Acrylics are not only cost-effective but also more durable than glass. It demonstrates more impact resistance than glass (Usually 10X more). Additionally, Acrylics offer a lustrous shine and a glossy finish!

Engel was founded in Austria in 1945 by Ludwig Engel. In 1952 ,the first injection molding machine was put into production.

Cast Acrylic is harder than extruded acrylic and is thus, more scratch-resistant. The manufacturing process of casting is labor intensive thus, cast acrylics are more expensive. Cast acrylics are homogenous and therefore have equivalent properties.

es of the polymer, usually targeted toward specific applications. Examples of the properties that can be adjusted in this way are impact resistance, chemical resistance, light diffusion, UV light filtering, or optical effects.

The manufacturing process of acrylic products can release highly toxic fumes thus, it needs to be handled with precaution. Anyone who is handling acrylic sheets should be provided with appropriate protective equipment and clothing. If not handled properly and the right precautions aren’t taken, acrylics could blow up during polymerization.

PMMA is also a cost-effective alternative to polycarbonate. If polycarbonate is too expensive to be applied to a project, PMMA is an excellent alternative. This is especially the case if the plastic requires a clear appearance bu not the properties of polycarbonate. There are various applications where one would prefer PMMA over polycarbonates such as jewelry, plaques, aquariums, windows, and display pieces. PMMA is comparatively lightweight and inexpensive in such cases.

Acrylics can be modified according to the requirements. They are available in clear as well as various tints and colors. Acrylics can also be texturized to produce a variety of finishes. In addition, Acrylics are also incorporated with additives to exhibit a particular characteristic such as scratch- resistance or glare reduction.

PMMA grades are known for their transparency! It allows 92% of the light to pass through, which is more than glass or any other plastic. This outstanding clarity makes it an ideal plastic of choice for various applications in the automotive, aviation, and marine industry such as rear lights, windshields, and plane windows.

It has been half a century since the initial development of injection molding machine. At present, 80% of the engineering plastics industry adopts injection molding. In recent years, the increasing needs of automobile, construction, household appliances, food, medicine and other industries have promoted the development and improvement of injection molding technology. At present, about half of the plastic machinery produced in China is injection molding machine, and from the perspective of major producing countries such as the United States and Europe, The output of injection molding machines is increasing year by year, accounting for the largest proportion in plastic machinery. And there are many excellent enterprise of injection molding machines rising from hundreds manufacturers in the world, especially chinese injection molding machines manufacturers has experienced rapid growth in the last two decades. But among all injection molding machines manufactueres in the world and in China, Which one under below lists will be Top 10 manufactuers in your eyes?

PMMA has unique properties such as low density, biocompatibility, UV resistance, easy molding, and delivering aesthetics while being cost-effective. PMMA has thus become a popular biomaterial for dental applications. It is commonly used for prosthetic dental applications such as the fabrication of artificial teeth, denture bases, dentures, orthodontic retainers, and crowns, and the repair of dental prostheses.

Acrylics typically allow 92% light transmission which is greater than glass or any other plastic. This light transmission property enables the acrylics to exhibit outstanding clarity. PMMA can thus, be applied in various optical-related applications.

PMMA was processed extensively to be further developed such that it can be molded into complex shapes that are required for the biological environment. The earliest application of PMMA was in dentistry and it was later extended to orthopedics for thigh and hip replacements. Since PMMA was lightweight, easily processed, and demonstrates low toxicity, it found various applications in the medical industry. It was, however, not cost-effective and thus, restricted for a while to the medical industry.

Since PMMA is lightweight and resistant to salt and cleaning products, it is extensively used for manufacturing windshields and windows. PMMA is also used for windscreens, windows, and canopies in airplanes as it can resist high inside cabin pressure and harsh UV radiations.

Avid promoter of the UK & Irish plastic manufacturing sector, linking all the industry's best suppliers to prospective customers

PMMA abbreviated for Polymethyl methacrylate is commonly referred to as acrylics. PMMA injection molding is a process where molten acrylic is injected into a cavity which upon cooling and hardening forms various types of plastic products. PMMA is applied to manufacture various plastic parts such as car windows, aquariums, and mobile phone screens. In this article, we have focused on PMMA injection molding in-depth to help you understand if it’s the best-suited material for your project.

PMMA can be molded into developing complex designs. PMMA injection molding process can reproduce a significant number of complex products that are identical in terms of shape, size, and weight.

PMMA demonstrates excellent physical properties such as extensive tensile strength, great flexural strength, and transparency, like glass. One of the most prominent properties of PMMA is that it resembles glass and it is thus often used as a replacement for glass. Additionally, it is a tough plastic material and is an excellent cost-effective alternative to the less resilient glass material.

Donghua Machinery Co., Ltd. is a core subsidiary of Datong Machinery Co., Ltd. It is a Sino-Hong Kong joint venture injection molding machine manufacturer that produces fully automatic injection molding machines and its auxiliary equipment. It was established in 1986. At present, the company has injection molding in southern and eastern China. The machine production base covers a total area of about 200,000 square meters. It can provide customers with a full set of injection molding machines and supporting equipment at one time. The injection volume is from 43g to 300,000g, and the clamping force is from 25 tons to 4,000 tons. There are more than 90 models and different specifications. The annual output is now 10,000 Multiple units.

Further developments and advanced technology developed a far more accessible and cost-effective PMMA that could be used for consumer applications. This particular development made PMMA a versatile plastic whose application spreads today, across several industries!

Ls machinery is a subsidiary of LS group, formerly known as LG Machinery Co., Ltd. headquartered in Seoul, South Korea, specializing in the production of injection molding machines since 1969. As a professional manufacturer of injection molding machines, it mainly produces electric molding machines, direct pressure molding machines, high-performance hydraulic molding machines and injection molding machines. The Chinese factory of LS Machinery Co., Ltd. is located in Wuxi high tech Industrial Development Zone. Its main products are electric forming machine and high-performance hydraulic forming machine.

In addition to prosthodontic applications, PMMA can be applied to a wide range of medical applications such as diagnostics, and incubators.

Acrylics do not turn yellow in the sun. Acrylics are also not affected by UV rays. They are thus ideal for shed windows and colored skylights. They are also popularly used for panels in home projects.

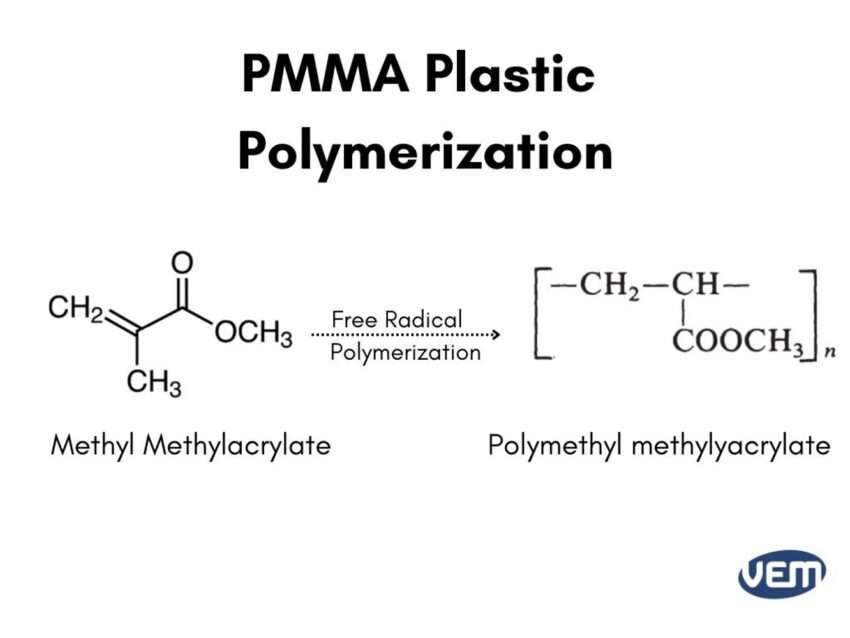

PMMA, abbreviated for Polymethyl methacrylate, is a transparent and rigid thermoplastic. PMMA is a polymer that is produced through the polymerization of monomer methyl methacrylate.

Great post! This is a very informative list of the top injection molding machine manufacturers in India. I would also like to recommend Futech Machinery (https://futechmachinery.com) as a reputable manufacturer of high-quality injection molding machines. They offer a wide range of machines to suit different needs and budgets. Thanks for sharing this valuable information!

Guangdong Yizumi Precision Machinery Co., Ltd. was founded in Guangdong, China in 2002. It has spread its wings all over the world. Specializing in the molding equipment manufacturing industry, it offers a one-stop solution as an equipment supplier, integrating the functions of design, research and development, manufacturing, sales and customer service. As a model enterprise in the equipment technology arena, Yizumi has currently established various commercial divisions, namely, injection molding machine, die-casting machine, rubber injection machine, high-speed packaging machine and robotic automation system , realizing diversified development in the equipment manufacturing industry. The global manufacturing bases of Yizumi span across the whole of China and outside of China. Besides, the total land in the world is over 600,000 sq.m and it has more than 3,000 employees.

Founded in 1966 in Ningbo, China, the Haitian Group has developed to one of the leading Corporate Groups within industrial manufacturing.Haitian International is specialized in the manufacturing the precise, efficient, energy saving and eco-friendly injection molding machines, and currently is possessing the injection molding machine production base with highest production and sales volume in the world and advanced technology at home.

Established in 1986, a subsidiary of Datong Machinery Co., Ltd., a Sino-Hong Kong joint venture injection molding machine manufacturer that produces fully automatic injection molding machines and ancillary equipment

In addition, PMMA has also been considered a safer option than polycarbonates as bisphenol A in polycarbonate has the potential to be hazardous.

Business items: development, manufacturing and sales of plastic processing machinery, mold processing system, automatic forming system and measuring equipment.

FANUC's business is comprised of three pillars of FA, ROBOT and ROBOMACHINE. The FA business encompasses basic technologies, consisting of NCs (numerical controls), servos and lasers, which are also applied to the ROBOT and ROBOMACHINE businesses.

Extruded Acrylics are produced through the extrusion method. Extruded acrylics are produced by pushing acrylic mass through a form thus, depending upon the direction of the flow, they have varying properties. Due to the production process, they are heterogeneous. Some of its properties are listed below:

design, development, manufacture of plastic processing equipment and related parts and accessories using proportional and servo-hydraulic technology, self-produced products, and wholesale of similar products.

Acrylics are weather resistant which means they are durable and can withstand storms, winds, and heavy rains. There is no degradation in transparency which is why the clarity also remains the same, unlike glass.

VEM Tooling has the expertise for your PMMA injection molding project. At VEM Tooling, we ensure that receive a great experience and dependable service! To better understand how VEM tooling can serve you for your PMMA injection molding project, contact us or request a quote today.

Acrylics are not toxic in their final forms but during production, their manufacturing process releases minute amounts of toxic fumes. Comparatively, the production of toxic fumes is not the same as other materials. Acrylic is classed as non-hazardous under OSHA regulations as it is one of the few materials that has very low toxic fumes released during its production and the final form is free of toxicity.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly