JACOBS MOLD & MACHINE - custom soft plastic molds

Author:gly Date: 2024-10-15

1. Production in same machine with double time of cavities compared with normal mold. It can increase production efficiency.

2. The disadvantage is that the injection molding of product #1 and product #2 cannot be injected at the same time, resulting in loss of efficiency.

The technology is relatively mature compared with the traditional over-molding tech, double color can be injected at the same time, high efficiency and good stability, this technology can be applied to a variety of products.

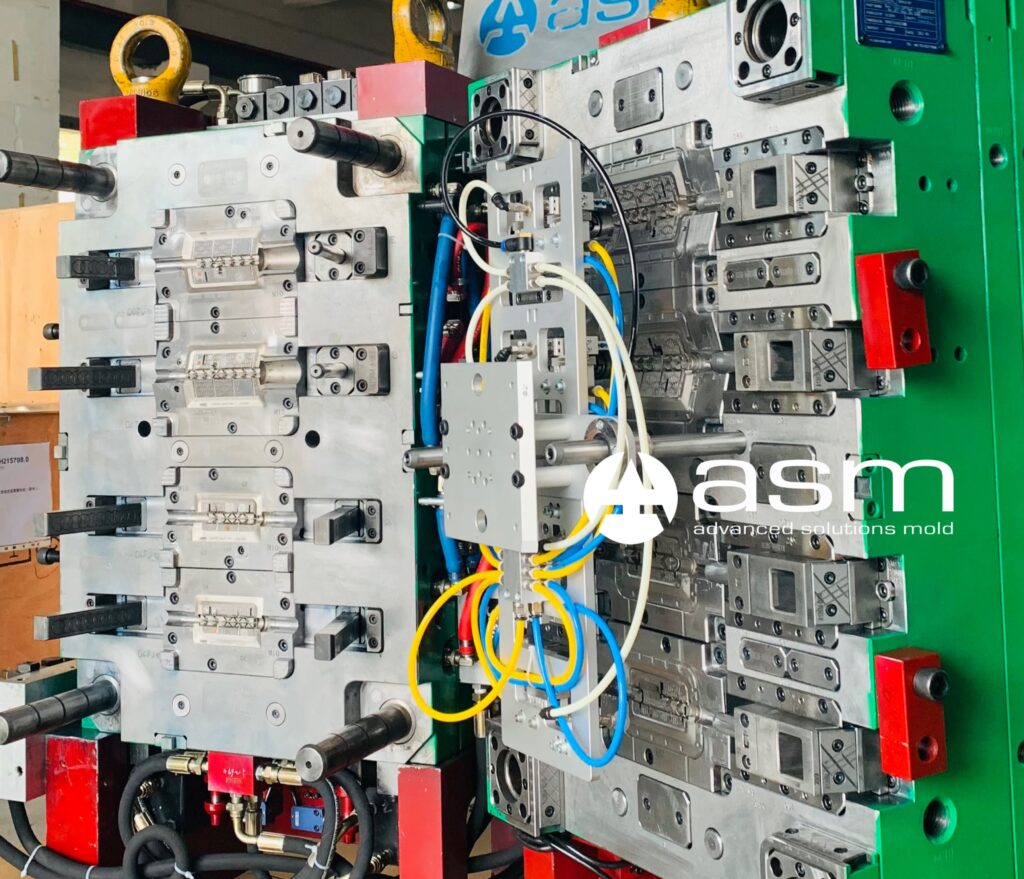

ASM has mastered this technology and has manufactured parts using multi-component molding process for many years. With 4 sets 2K injection machines in house, and with our leading 2K technology, we are capable of manufacturing different types of 2K molds.

2. With rotation core method, it can realize the various injection of material / color. Especially for small product, it will be more controllable on part dimension than rotary table method.

Multi-component molding is an efficient and cost effective technology for molding custom plastic parts with two or three plastic resins or colors in a single operation, and at faster cycle time and flash free.

1. Use robot arm to switch the molding part instead of rotary table method, it will be helpful to save investment cost of equipment.

1. Cost efficiency, it reduced core side compare with transfer method, but it still can achieve the 2k injection process in one mold.

4. Mold rotates on horizontal turn table, which is more stable than vertical rotation and has no inclination. It helps for life of mold, especially large molds.

2. Good quality stability: the two molding steps can be done in one cavity and it can avoid part warpage issue during the mold open and part transfer. It is more stable than over-molding method.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly