Injection Moulding Design Guide - plastic injection part

Author:gly Date: 2024-10-15

Structural Foam Molding is more than just another manufacturing process. It’s a testament to the advancements in the world of plastic production. Whether you’re looking to reduce material consumption, produce large parts, or prioritize sustainability, Structural Foam Molding offers a solution. As industries continue to evolve, processes like these will play a pivotal role in shaping the future of optimized part design.

Sustainability is a growing concern in today’s world. Structural Foam molding enables parts to consist of up to 100% post-industrial or post-consumer materials. This not only diverts waste from landfills but also ensures that all Structural Foam products are 100% recyclable. Furthermore, the low-pressure molding technique consumes less energy and material per pound compared to other molding methods.

The tooling process for Structural Foam Molding involves the use of a cavity injection mold. Typically, manufacturers construct these molds from machined aluminum billet or castings for precise and long-lasting results. This process doesn’t need steel molds, saving money on capital costs compared to other molding methods.

Combining smaller components into a single large part can reduce complexity. After serving the transportation and powersports industries for many years, our teams understand how to save you time. Converting numerous small parts and assemblies into a single molded part makes your downstream activity more efficient. Imagine creating vast structures from plastic that you previously thought were impossible.

Structural Foam Molding is a unique process that has evolved the world of plastic manufacturing. By mixing nitrogen gas with a plastic material, this method has several advantages that set it apart from regular injection molding. Let’s dive deeper into the intricacies of Structural Foam Molding and understand its significance.

Hand Lay-UpSpray-UpResin Transfer MoldingReaction Injection MoldingCompression Molding – SMCCompression Molding – DLFTStructural Web Molding

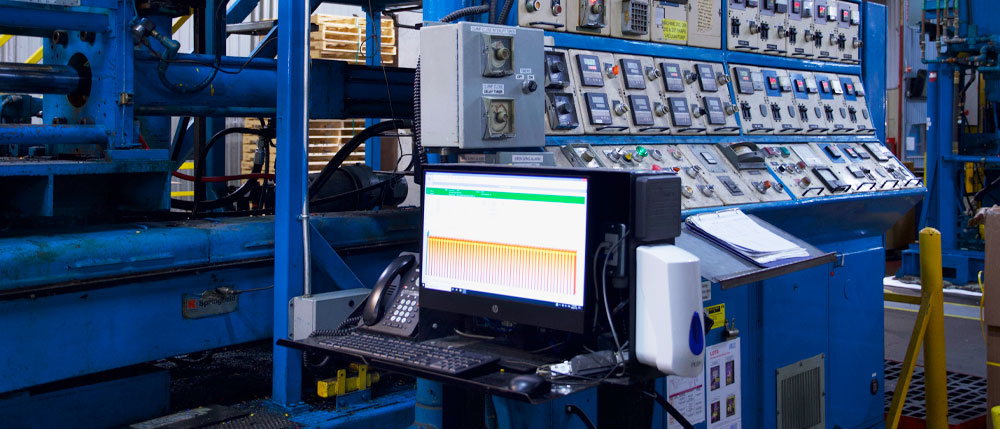

Structural Foam Molding is a game-changer for producing large parts because it can accommodate large shot sizes. At Core Molding Technologies, our machines can accommodate up to 100 pounds of material in a single shot.

Structural Foam Molding can decrease part density by 10-30%. This reduction doesn’t compromise the strength of the product. In fact, the resulting parts have an impressive strength-to-weight ratio, making them both efficient and cost-effective.

Efficiency is at the core of Structural Foam Molding. The process allows multiple molds to run simultaneously, leading to significant savings in cost and lead times. Parts molded at the same time with a single “family” tool are more consistent. Parts made together using one “family” tool will fit and have the same color.

One of the challenges with traditional molding processes is the internal stress they introduce into the part. Structural Foam Molding, with its lower tonnage pressure, minimizes this stress. The resulting parts feature enhanced uniformity, dimensional stability, and reliability under various environmental conditions.

The gas-assist molding process utilizes a chemical blowing agent to move the nitrogen through the part. Structural Foam molding creates a robust outer layer with an industrial appearance and a cellular center. This unique finish ensures that the product is lightweight yet strong, making it ideal for a range of applications.

Transitioning to Structural Foam Molding can lead to significant savings in logistics. We have replaced heavy materials like concrete and steel with lightweight foam to transport and install things in a different way.

Structural Foam Molding is the combination of inert nitrogen gas and thermoplastic resin. This blend is crucial for creating distinctive solid outer skin with a cellular interior for molded parts. The cellular interior not only reduces the weight of the product but also enhances its strength and durability.

Structural Foam Molding offers a plethora of design options. Core Molding will meet your design requirements based on colorants or textures. This flexibility eliminates the need for additional post-processing, which can be both costly and environmentally detrimental.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly