Injection Moulding Businesses for Sale - plastic moulding business for sale

Author:gly Date: 2024-10-15

As well, businesses looking for a cost-effective alternative to the high upfront costs often associated with traditional plastic injection molding may also benefit from low volume manufacturing services.

Low volume plastic injection molding is a great solution for organizations that need to create frequent prototypes. This can include medical industries as well as automotive industries.

We have one of the most comprehensive injection moulding facilities in Australia with 14 state of the art, energy efficient moulding machines, all coupled with robotics ensuring consistency through quality and cycle time. A Plus has the capacity to mould products from 5 grams in weight up to a massive 12.5kg, along with the ability to lift 21 tonne moulds using our unique overhead crane systems.

Polycarbonate (PC) has a high heat tolerance which makes it well suited for automotive components or machine parts that are exposed to high temperatures repeatedly in the course of normal use.

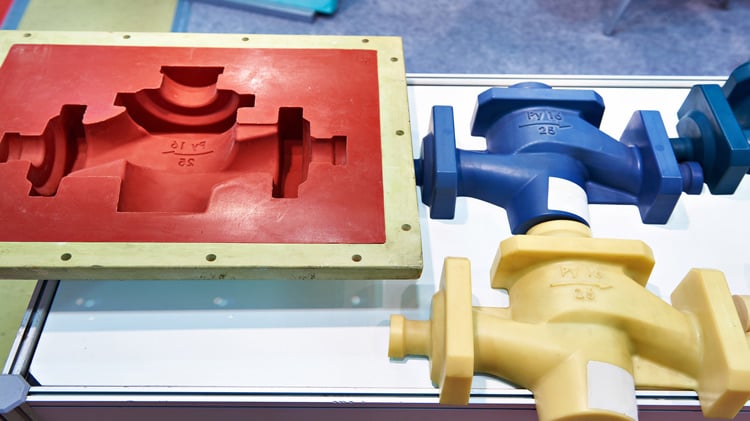

You'll also need to have a prototype created to test out the molding process. Low volume plastic injection molding is fairly simple in theory, but there are some intricacies that can make or break your part depending on how well they're executed.

Low volume plastic injection molding is usually used in the prototyping stage of product development as well as the functional testing stages. Low volume plastic injection molding is also used to produce end-use parts for low production runs, such as those used by Apple and Tesla.

With over 35 years of experience in the injection moulding industry, A Plus Plastics has 14 state-of-the-art, energy efficient moulding machines producing parts with consistent quality and precise tolerances, ensuring the same high-quality products every time.

Acrylic plastics are affordable, versatile materials that are very easy to work with. That said, they cost more than glass and scratch easily. As well, its service temperature is too low for some industrial applications.

A Plus Plastics can process basically any engineering polymer that can be injection moulded, including but not limited to the following:

Polycarbonate is strong and naturally transparent, making it suitable for applications that require an optically clear material with excellent dimensional stability. It is able to maintain physical properties at a high temperature as well as offer great impact strength.

Material is fed into a plastic injection moulding machine where it is heated, mixed, and forced into the mould cavity where it cools and hardens to the configuration of the cavity.

Nylon is resistant to many chemicals, making it ideal for medical manufacturing applications. Nylon is a good choice for parts that need to be able to hold up well in a chemical environment.

The type of low volume plastic you use will depend on your application requirements and whether you are prototyping or producing.

If you want to get started with low volume plastic injection molding the first step is adequate tools. Low volume injection molding requires the use of new molds, which can be purchased online or at your local machine shop.

From product design and prototyping, to scalable mass manufacturing of your products, the specialist teams at A Plus Plastics support both domestic and global businesses to commercialise innovative and profitable products.

Whether you need custom-moulded parts or high-volume production runs, we can deliver the results you need on time and with a high level of consistency. Our commitment to quality, efficiency, and customer satisfaction makes us your ideal partner for your next project.

Low volume materials are often not available at retail outlets but are custom-made for the customer's product. Low volume plastics are often produced with high levels of detail, which makes them useful in prototyping and development processes where fit is important.

Low volume injection molding refers to the production of small batches (typically less than 1000 pieces) of plastic parts. Similar to low volume production methods for metal or wood, Low volume plastic injection molding is usually done with a smaller dimensioned machine that can be used for prototyping.

Once you've created a successful prototype for low-volume plastic injection molding you'll need to send it out to an experienced plastic injection molding company.

ABS is an engineering-grade thermoplastic that is more expensive than acrylic, but offers greater strength and rigidity. It also has a higher service temperature of up to 100°C (212°F) making it suitable for industrial applications that require exposure to high temperatures repeatedly in the course of normal use.

A Plus Plastics is leading the Australian plastics industry in automation, utilising robotics to minimize labour costs in a forever tightening manufacturing market. Our 14 machines utilise either 3 or 6-axis robots to extract parts from the machines, which enables our skilled operators to often work on 2 or 3 machines at one time. Our robots also guarantee consistency of cycle time, ensuring we can give our customers the most competitive price.

If you've ever found yourself in the position of needing a small number of plastic parts for your company, you've likely wondered how you can go about getting them made. Low volume plastic injection molding is an affordable way to produce high-quality components in low numbers when compared with other manufacturing processes like machining or casting.

It is important to make sure you are using a reliable supplier for your plastic injection molds, because they can be expensive to remake if they don't turn out as expected.

Low volume manufacturing services are frequently sought after by businesses looking to produce small batches (typically less than 1000 pieces) of products.

If you have a new product design or custom moulding enquiry, click here to download the New Product & Custom Moulding Questionnaire. This form will assist in gathering the required information to quickly assess the manufacture of your product.

A Plus Plastics is your one-stop for the delivery of turn-key componentry to value add to existing supply chains. A Plus has the ability to not only mould components, but has a range of assembly services allowing you to focus on your core business activities. Our flexible & dynamic work cells provide an excellent opportunity for customers to reduce costs and add value to their supply chain. Sub assembly allows you to meet your lean manufacturing objectives by providing seamless delivery and execution typically at a lower cost than if performed in your facility.

Low volume plastics are typically used in prototyping and product development processes, where the parts produced with low-volume injection molding machines can be tested for functionality or fit before they go into full production.

Low volume plastics are typically used in medical, automotive, and consumer electronics industries for prototype parts or as functional components. Low volume plastic injection molding also allows you to do multiple iterations on a product design without having to go into production with it each time, which saves money and time!

Injection moulding is capable of producing high volumes of parts in a short amount of time and the injection moulding process involves several steps.

Our injection moulding process generates minimal waste. Any excess material can be easily recycled and reused in subsequent production cycles.

Many companies use ABS in their low volume plastic injection molds, as it’s tough and durable. ABS can be used to make a large range of items, such as automotive components and medical devices and instruments.

A Plus Plastics specialises in plastic injection moulding (also spelled molding), a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials.

At A Plus Plastics, we are a trusted moulding maker that specialises in providing high-quality injection moulding services. We use state-of-the-art molding 3D technology to ensure that each part is produced with the highest level of accuracy and consistency. Our experienced team of customer moulders has the expertise to handle any project, no matter how complex.

RCO Engineering specializes in low volume plastic injection molding for businesses of all kinds. We have experience creating products for aerospace, automotive, and defense industries and can help turn your ideas into a reality.

Capable of producing high volumes of parts in a short amount of time due to the ability to produce multiple identical parts in each cycle.

Injection moulding allows for the production of complex and intricate parts that would be difficult or impossible to produce any other way.

Other common low volume injection molded plastics include Polycarbonate (PC), Nylon, and PPSF. These plastics are also tough and durable, but also have different properties than ABS plastics.

Low-volume products are typically produced as prototypes or functional components, such as those found in medical devices or automotive parts.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly