Injection Molding Services for Custom Parts - low cost injection molding

Author:gly Date: 2024-10-15

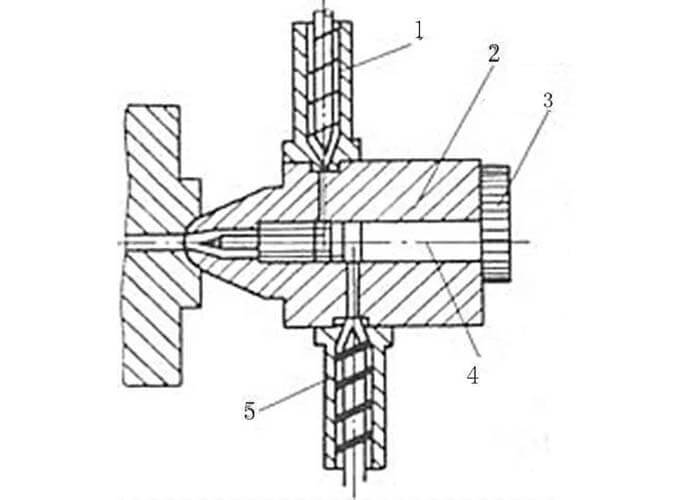

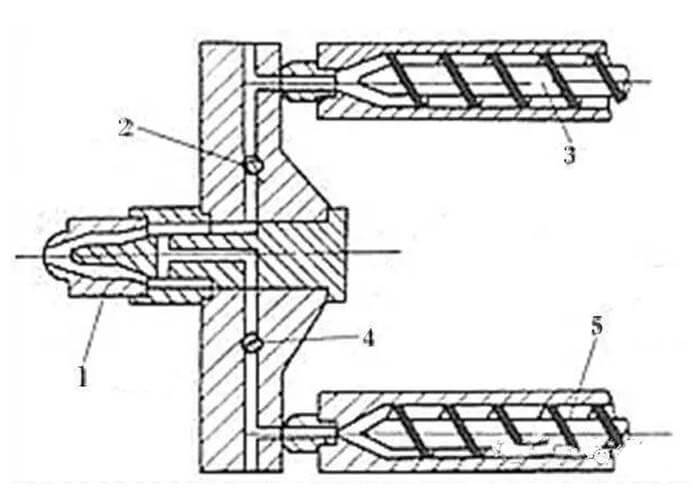

Also, there are two barrels 1 and 5, and the nozzle structure is a little special. In addition to the normal nozzle function, it can also be rotated by gear 3 attached to the rear.

The four types of acetal we stock are all semi-crystalline thermoplastics. Delrin 570 differs from the others because it is 20% glass-filled to provide additional strength, stiffness, creep resistance, and dimensional stability. POM comes in two structural varieties, homopolymer and copolymer. The essential difference between these two is in the chemical structure, with the homopolymer using a chain of the same monomer (a carbon-based molecule), and the copolymer using multiple kinds of monomers to form the chain. The static dissipative version of POM is also a copolymer and a good choice for when you want to avoid issues with static discharge, such as near sensitive electronics where one zap from your finger can destroy a circuit board.

Widen the contact area, make grooves to increase adhesion, use core pull on the first shot, inject the material of the second shot into the first shot, mold the first shot Make the surface of the surface as rough as possible.

Our digital factories create prototypes and low-volume parts fast, while our manufacturing network, offers advanced capabilities and volume pricing.

Proto Labs, Inc. 5540 Pioneer Creek Dr. Maple Plain, MN 55359 United States P: 877-479-3680 F: 763-479-2679 E: [email protected]

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials.

Get machined parts anodized and chromate plated with our quick-turn finishing option. Eligible materials include aluminum 6061/6082 and 7075.

Tough Black (Loctite Henkel 3843) and Ceramic-Filled (BASF 3280) are two new advanced photopolymer materials now available for 3D printing.

Two-color mold: A mold that injects two plastic materials into two molding machines with the same injection molding machine, but the product is injected only once.

Acetal (polyoxymethylene or POM) is a strong, stiff, wear-resistant thermoplastic with excellent dimensional stability. It is also known by the trade name Delrin.

During molding, after the melt is plasticized in the barrel, open/close valves 2 and 4 control the order of the melt entering the nozzle and the proportion of material discharged, then the nozzle is injected into the mold cavity increase. Various plastic injection molding products with different color mixing effects can be obtained.

Small lens double shot design: The first shot is opaque, the second shot is the lens, the first shot is as high as possible and the second shot is PMMA.

Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

This type of molding process, also commonly referred to as two-component injection molding, is usually completed with a set of molds and requires a special two-color injection molding machine. Generally, there are the following requirements:

During molding, different colored melts are plasticized in barrels 1 and 5, gear 3 rotates the rotating shaft 4, and different colored melts alternately enter the mold cavity to obtain different colors and colors. A patterned plastic product that radiates from the center to the periphery.

DGMF Mold Clamps Co., Ltd mainly offers a wide range of Mold Clamps and Mold Components. Used in processing machinery especially on plastic injection molding machines, and pressure dies casting machines.

All forms of acetal have a lot going for them for machined parts. One of its most important features is its machinability. Endmills cut through it like butter, and those cuts tend to be clean and smooth. At the same time, precision parts can benefit from its high dimensional stability and tolerance for temperature and weight. Related to that is acetal’s strength and stiffness, which help it tolerate heavy loads. Acetal is also suitable for high-moisture environments as it is unlikely to swell in those conditions. Last but not least, that toughness means it’s also suitable for applications that experience friction. In some situations, it can even replace heavier metal parts, allowing for light-weighting.

Transparent and opaque dual shot design for decoration: the first shot is an opaque material, the second shot is a transparent material, the opaque material is usually hot PC, the second shot transparent material is PMMA or PC. Your PC should be sprayed with UV to protect it. PMMA can be UV or enhanced. If there are letters on the surface, you need to select UV.

Today, we talk about the 2K injection molding technology, a molding method in which two different colored plastics are injected into the same mold.

Matching materials for two-shot injection molding must meet two basic compatibility requirements: adhesive compatibility and process compatibility.

You can improve the practicality and aesthetics of plastic parts by displaying them in two different colors, or by displaying regular patterns or irregular moire-like patterns on plastic parts.

There must be a constant temperature difference between the melting points of the two materials. Normally 60 ° C is recommended, and at least 30 ° C is recommended. The material of the first shot has a high melting point temperature. Usually, the first shot is a PC. Or on PC / ABS, the second shot is TPU or TPE. , PC thickness is 0.6-0.7mm, the software is over 0.4mm.

There are two barrels, and the structure and usage of each barrel are the same as a normal injection-molded barrel. Each barrel has its own passageway that connects to the nozzle, and on-off valves 2 and 4 are also attached to the nozzle passageway.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly