Injection Molding - Resources for Scientific Molding and ... - scientific inject

Author:gly Date: 2024-10-15

Stage 1: The raw materials are loaded into both injection canisters, where they are exposed to heat and pressure so that they can maintain that viscous state necessary for injection to occur. The first molding crate is opened, and the first injection is shot into it as the other crate remains closed.

Design Range: With two-shot injection molding, you are free to try out as many designs as you want, even those that may seem to be impossible. The wide range of options available to this technique makes it a cost-effective and covenant method of making clear plastic and metallic mold products.

Like most molding processes, there are certain raw materials that are popular with people who use two-shot injection molding for their manufacturing needs. Each has the qualities needed to produce a specific type of end-product. These materials include the following.

Dive into Flash, a common plastic defect, in our FREE webinar! Our injection molding expert shares science-based strategies to avoid issues. Join us this afternoon: https://bit.ly/FlashWeb24 #InjectionMolding #SkillsTraining #skillsforsuccess

Unlock pro-level plastics processing skills with Paulson's certification seminars! Join our intensive, instructor-led classes to boost consistency, cut costs, and improve efficiency. Whether you're experienced or new to the field, gain valuable strategies from top-tier instructors. Check out our upcoming seminars! https://lnkd.in/eaD3kZNQ #plasticsindustry #training #certification

Burn marks and short shots? Oh my! Learn the causes and solutions in our latest tech webinar here: https://lnkd.in/dEH_gGJR #learningwebinar #injectionmolding #plasticsengineering

Reduced Post-Processing: The two-shot injection process is all-encompassing, everything is done in one move, and this cuts down the need for further processes like post-processing, which usually increase the cost, time, and energy consumption for nothing.

Better Aesthetics: The process is handled in a controlled environment, and this makes it easy for any other modification to be added. This could be patterns, logos, texts, or colors that further enhance the overall appearance of the end product. These auditions are permanently engraved on the product, making it look more natural and complete.

Rubber: Rubber comes in many forms, and the most commonly used is a synthetic rubber, thanks to the many applications it can be used for. It is easier to melt, and mold is easily available, and has a very wide range of options as far as designing is concerned.

Stage 2: The press on the first crate is opened, and the part that has been freshly created from the first injection is quickly transferred robotically to the second mold. This means that the first chamber is now free again, ready for the second injection.

Thermosets: These are almost similar to thermoplastics, only that they cannot be reused. They are one-time-use plastics that are used to make various domestic and commercial tools. They are not good for the environment and for this reason they are not used too often.

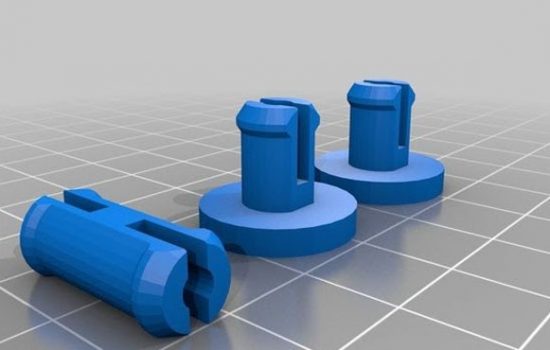

2K injection molding, also known as two-shot injection, is a process that uses two injections instead of one. Like any other molding technique, the two-shot injection has become very popular with manufacturers worldwide for various reasons. But how exactly is it carried out step by step? This is what we are going to look into today. We will be exploring the entire step-by-step process of two-shot injection molding, the machines used, the raw materials involved,,and finally a brief look at some of the benefits it brings to the table.

Nylon: This is among the most common materials used and can be found everywhere on the planet. It is used to make strong mechanical parts that are used in the automotive, aerospace and other industries.

Calling all #NPE2024 attendees! Paulson Training Programs, Inc. is presenting at NPE2024's General Education Session and hosting live in-booth molding simulation demos! Be sure to catch these dynamic and informative educational events to help you go further in plastic part production---PLUS! Lucky attendees may get a Paulson T-shirt! There's so much to learn with Paulson! Visit us in booth #2973. Learn More: https://lnkd.in/eWQQkghz #injectionmolding #training #learningisfun #plasticsindustry

Step 3: The press on the second chamber is closed, and the second injection is shot into the now open first chamber until it fills up just like the first one. This is to ensure uniformity of the end products.

Calling all INJECTION MOLDERS! GAME ON! Flex your molding muscle and win! #injectionmolding #learningisfun https://bit.ly/SimGameOn

Announcing the winners of the March SimTech Injection Molding Challenge. Congratulations to FIRST PLACE winner AGS Technology! NOTE: they're also ProMolder 1 grads. Might there be a coincidence? Hmmm.... Get the scores and more here https://lnkd.in/eBtWJMCk #winners #injectionmolding #plasticsindustry #plasticsengineers

April Showers bring Molding Powers! Let's see yours in our latest SimTech Injection Molding Challenge! Where molders from around the world test their molding skill using the plastics industry's most advanced injection molding simulation learning tool --- SimTech™! https://lnkd.in/eaE9Viwf #injectionmolding #plastics #plasticengineers #challenges #learningisfun

The two-shot injection molding process is similar to the regular injection molding technique, the only difference being that this former uses two injection nozzles that are released into a mold that has two crates. The process takes place in 4 main stages.

So why are manufacturers clamouring to use the 2k injection molding technique for most of their production needs? The use of this technique has been gaining popularity, and that’s not by accident. The following are some of the reasons why.

It's coming! Are you ready? A new season of thrilling monthly molding challenges are heading your way, with the season kick-off next month. Learn what's new and what you could win. Get the details here! https://lnkd.in/eps6PpjF #learningisfun #challengeyourself#injectionmolding #learning #plasticsindustry #plasticsengineers

Metal: There are different types of metals that are used in injection molding, and the most common ones include steel, aluminum, and brass. These three are cheap, widely available, and molding them is much easier. Products made from them are also in high demand as they last longer.

Glass: Glass is a rare molding raw material but is used on some special occasions. It is a little trickier to mold compared to the other materials on the list, and the end products are usually used in the medical industry.

Two-shot injection continues to gain popularity in manufacturing, and this means that very soon, the future will be ruled by those who were clever enough to jump on this bandwagon when it was picking up. Many other molding processes work in the same way, it all comes down to what you need to achieve and the product you plan to make. For more information on two-shot injection molding, visit our website at your nearest convenience or drop us a call and have all your concerns addressed by a team of experts to your satisfaction.

BIG NEWS! Paulson Training Programs, Inc. enters exciting new era powered by Certus, a leading professional training and certification provider. Read the official Certus press release here. https://lnkd.in/e8EsVzSc #plasticsindustry, #plastics, #training

Boost your skills with a Certification seminar from Paulson! With our top-tier instructors you'll learn to optimize a process in no time and all with actionable strategies and best practices. REGISTER TODAY! Invest in training and pave the way to greater profitability. Learn more here: https://bit.ly/BoostSkills #WorkforceDevelopment #BeSkilled

Thermoplastics: These are finely cut plastic materials that can be reused as many times as possible without losing any of their good attributes. It is loved mainly due to their low cost, low melting temperatures, and the fact that they are eco-friendly.

Improved Efficiency: The process doesn’t require too many hands on the job. With most of it being automated, you end up saving money that would have gone into covering labor costs, and in return, you get precise robots that are able to handle the same work at ten times the speed and accuracy.

Step 4: The second chamber is opened again, and the second part is transferred to it again using robotic arms. The process continues this way as fast as it can until the required number of products is clamoring attained.

Improved Quality: The precision involved in this technique is off the charts, and when you combine that with the meticulous steps it follows and the raw materials used, the end product comes out with the best qualities one could ever wish for. This boosts customer confidence in your products and increases sales.

Part Consolidation: The traditional methods of manufacturing usually split the production of different parts, which are then joined to make a single component. This is a lot of work and wastage of resources. Two-shot injection molding ensures that the number of parts needed is reduced significantly, saving time, energy, and costs.

Paulson Training develops and markets comprehensive training solutions to the plastics industry. We deliver state-of-the-art interactive training via on-line, classroom/hands-on seminars and custom onsite instruction to plastic processors in injection molding, extrusion, blow molding and thermoforming. Paulson's programs are in use by thousands of individuals and hundreds of companies including more than 100 academic institutions in the US and abroad that integrate Paulson as part of their engineering curriculum. We work with plastics processors one-on-one to develop a training solution that will meet and exceed expectations. All of our training is developed with the top experts in the industry and every program undergoes a very rigorous independent evaluation by recognized experts before being released. This attention to quality is what makes Paulson Training the recognized industry-standard. Talk to one of our training specialists to discuss your specific training needs. We will put together a customized package from our training library for your evaluation.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly