Husky Technologies | Injection Molding Packaging Solutions - molding company

Author:gly Date: 2024-10-15

MSI Mold has been helping customers with their plastic injection molding needs since 2005. We have built more than 2,500 molds for plastic injection and have shipped over 25,000,000 parts and assemblies to a long list of industries. Customers choose MSI Mold to be their injection molding supplier for our outstanding customer service, consistent high quality injection mold parts, and reliable on-time deliveries.

A full service plastic injection molding company dedicated to USA manufacturing excellence. Our complete in-house control over the mold build and injection molding process cuts costs and gives you single source responsibility for quality.

When our customers need a high-quality and reliable injection molding company, we listen to their needs and go to work. Steady demand for our services has continued and we were proud to grow into our brand new facility in 2022. Come visit us and you will walk away confident to make us your injection molding supplier.

To know how big or how small your part can be with injection molding, we think it’s best to know how the actual process works first. Because, if the process doesn’t seem manageable for you and your company, then it might be best to follow a different route to produce plastic parts.

With injection molding, all you have to do is design the mold and let the rest play out. Keep in mind that even though injection molding is quite simple, the designing behind the mold is much more complex. Once you have the finalized look, all you need is a small tube for the “injection” to take place and the machinery will take it from there.

A full service CNC machining company supplying custom parts with USA manufacturing reliability. Our in-house control over the complex machining process and quality assurance cuts costs and offers you 100% compliance to your needs.

Inside the small tube is where the magic happens. You’ll streamline plastic beads through it, where they’ll get heated and fed into the mold. From there, the metal mold will keep the beads in place until it’s “molding” and cooled enough to be released. Once the desired temperature is reached, both sides of the mold will separate and the plastic part within will be ejected and ready for packaging/selling.

Get high-quality, affordable custom plastic parts and molds made in the USA by our experienced injection molding company. Your injection molds and production parts are manufactured completely in-house. Now offering custom machined parts - ITAR : ISO 9001 Compliant

Custom plastic injection molder based in San Diego County, California. Since we were established in 1978, we have had one mission: To produce the finest parts, at the lowest prices.

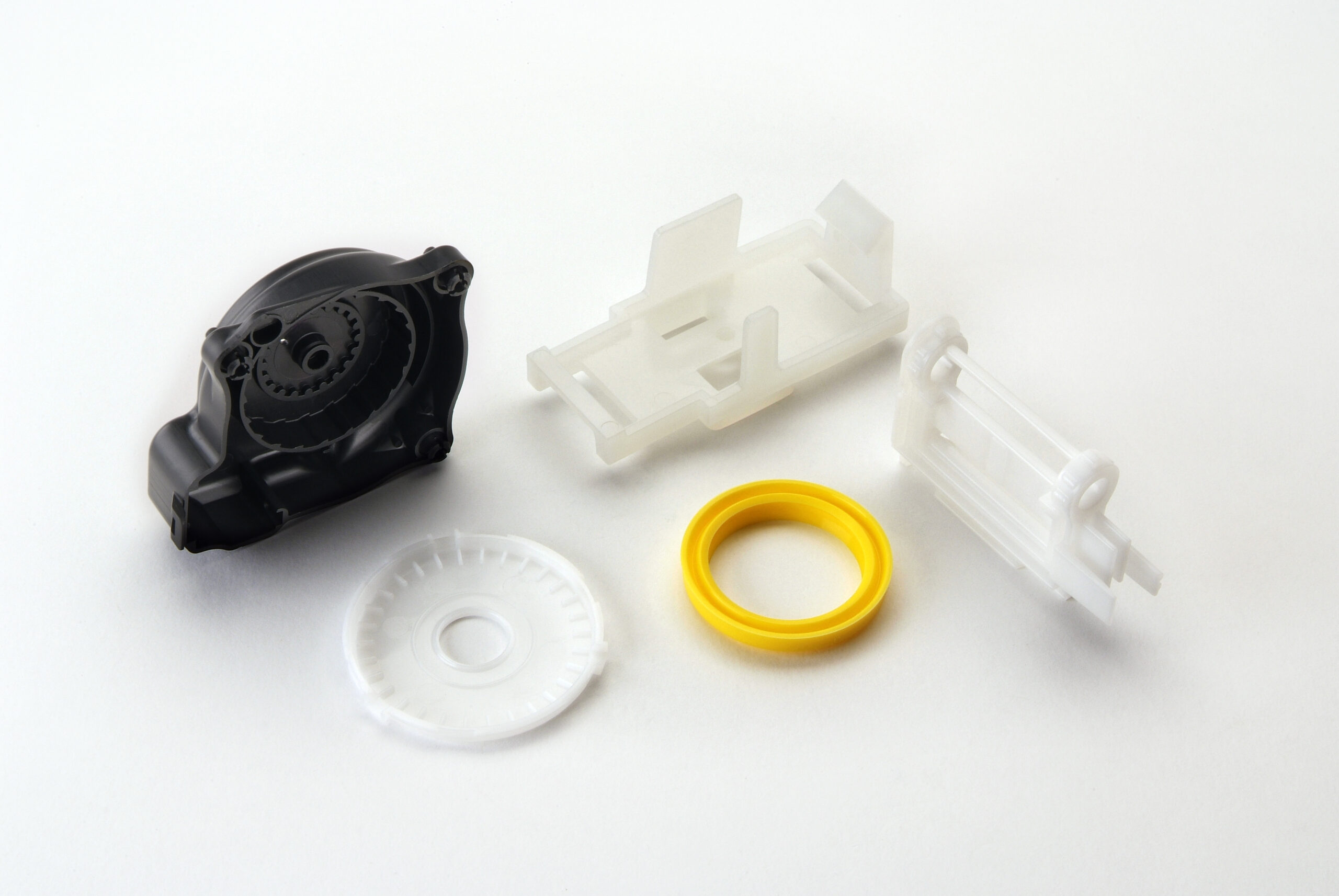

Injection molding is one of the most versatile manufacturing processes around. You can create just about any type of product, including but not limited to car parts, kitchen utensils, medical devices, toy action figures, and so much more. Even still, no matter how great the method is, injection molding still has its disadvantages.

We give our customers exceptional customer service and a hassle-free sourcing experience. We guarantee consistent high quality injection molded parts, Precision CNC machining, no hidden nickel and dime charges, and fast delivery of your production. Your satisfaction is our main focus.

Before getting knee-deep in the injection molding game, you’ll want to know what kind of pros and cons come with the process. Will you have limitations? Will your company excel beyond belief in certain areas compared to that of other areas? You have to know before you potentially make a mistake that your company won’t be able to recover from.

In this article, we’re not going to talk about ALL of the advantages and disadvantages. Instead, we’re going to focus on how big or how small your injection mold has to be/can be. Let’s get into it.

As with any design process, injection molding has its weaknesses and limitations, no matter how versatile it can be. Some things to consider include:

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly