How much do you know about mechanical injection mold ... - slide injection moldi

Author:gly Date: 2024-10-15

Controlled removal of material using a laser beam to create designs, patterns, or markings on the moulded surface, ensuring precision and permanence.

Deposition of a thin metal layer onto the moulded surface through an electrochemical process, improving aesthetics, conductivity, or corrosion resistance.

1 “Punch shift” mold has two concave molds and one convex mold. When the first barrel is shot, punch is closed with the first die. Complete injection of the first plastic. After the first plastic is solidified, concave and convex molds are separated, semi-finished product formed of the first plastic stays in punch and moves with punch to a position aligned with second die. After injection moulding machine is closed, second barrel is injected with second plastic. After second plastic solidifies, injection moulding machine opens mold and takes out complete product.

The choice of material depends on factors such as desired properties (e.g., strength, flexibility, transparency), environmental conditions, and application requirements. Geomiq can help you recommend the best material for your specific needs.

Injection moulding allows for a huge range of materials with production-grade properties, from durability and biocompatibility to impact resistance. We offer over 130+ injection moulding materials or can support free-issue material directly from you.

Application of paint or coatings onto the moulded surface using a spray gun, allowing for customisation of colours and finishes.

Injection moulding supports numerous materials, including ABS, HDPE, HIPS, LDPE, PA6 (Nylon 6), PC, PC/ABS blend, PE, PMMA (Acrylic), POM (Acetal/Delrin), PP, PS, PU (Polyurethane), and PVC.

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

Application of specialised coatings to enhance durability, resist scratches, or provide specific properties such as UV resistance or chemical resistance.

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

2. Compared with ordinary plastic injection molding products, two shot molding plastic products should adopt higher parameter value for melt temperature and injection pressure at the time of injection. Main reason is that mold flow path in double shot injection molding is relatively long, structure is relatively complicated, and flow resistance of injection melt is large.

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

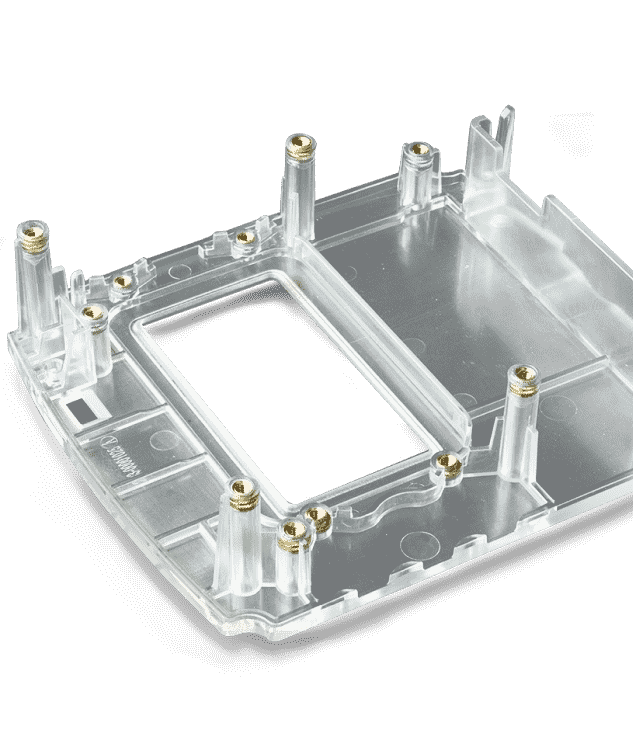

Integration of threaded metal inserts during the moulding process to provide durable and secure attachment points for screws, bolts, or other fasteners.

Producing injection moulding plastic parts at scale can be challenging, which is why we offer fully managed production runs with dedicated specialists.

3. Two shot molding plastic products should use raw materials with good thermal stability and low melt viscosity to avoid decomposition due to high residence temperature in flow channel due to high melt temperature. Plastics used in many applications are polyolefin resins, polystyrene and ABS materials.

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

A printing method where a silicone pad transfers ink onto the moulded surface, allowing for detailed and multicolor designs on complex or contoured shapes.

Application of ink through a mesh screen onto the moulded surface, ideal for large and flat areas, offering vibrant and consistent prints.

The cost is influenced by factors such as part complexity, material selection, tooling cost, production volume, surface finish requirements, tolerance specifications, and any additional features or inserts.

At Geomiq, we understand the value of your time and are dedicated to helping you save more of it. After uploading your files, we provide a quote within one business day. Our network of highly experienced partners ensures that your injection moulding parts are of the highest quality with short lead times.

We offer a 1 to 1 experience with an injection moulding project manager with over 25 years of experience. This ensures you get only the best advice and support throughout all stages of production, from tooling design, injection points, and surface finishing to packaging recommendations. Expect nothing less than affordable and exceptional service.

Our engineers have 50+ years of expertise and offer innovative processes with maximum responsiveness. Our T1 sampling process provides high-precision injection moulding. We're experts in rapid tooling, family moulds, multi-cavity moulding, and over-moulding.

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

SPI offers standardised textures and gloss levels to enhance the appearance and functionality of injection-moulded products.

A printing method where a silicone pad transfers ink onto the moulded surface, allowing for detailed and multicolor designs on complex or contoured shapes.

Incorporate preformed metal or plastic inserts into your injection-moulded parts to increase functionality or aesthetics. Geomiq can provide inserts, work with free-issued inserts, or use inserts you specify.

Custom injection moulding can produce tight tolerances with high precision. This is important for parts requiring high accuracy.

The high production output rate of custom injection moulding makes it extremely cost-effective, allowing manufacturers to benefit from economies of scale and increased profit margins.

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Double shot injection molding can make two different characteristics of resin and color into a single two-color product, which can reduce assembly and post-processing of molded products, save cost of dissolution and printing, increase aesthetic appearance of product, and enhance grade and added value of product. Below I will introduce difference between advantages of double shot injection molding, molding principle, structural form, technology and overmolding.

Deposition of a thin metal layer onto the moulded surface through an electrochemical process, improving aesthetics, conductivity, or corrosion resistance.

See our case studies in action. Discover how we turn ideas into products with our prototyping and manufacturing capabilities.

Injection moulding is versatile and can produce a wide range of products, including automotive parts, consumer goods, medical devices, electronic components, packaging materials, and more.

Geomiq has the capacity to take on various injection moulding projects, from prototyping to production. We support low-volume injection moulding with no minimum order quantity, as well as mass production and ongoing call-off orders that align with your needs. We seamlessly handle challenging projects with complex requirements, be it complex part geometry, specialist materials, extremely tight tolerances, or specialist finishing. Geomiq utilises the very latest injection moulding technologies to deliver quality fast.

Waste generation is minimal in custom injection moulding, as this process uses only the required amount of material to create parts. Furthermore, most injection moulding materials are 100% recyclable.

Lead time varies depending on part complexity, mould design, and production volume. With Geomiq, you can receive parts in as little as 8 days.

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

Produce flexible, durable, and high-precision parts from soft/flexible materials in batches or production runs. Shores from 20 - 90 (A).

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

Application of ink through a mesh screen onto the moulded surface, ideal for large and flat areas, offering vibrant and consistent prints.

Double shot injection molding usually refers to molding of two colors or different kinds of plastics. Since two sets of injection units and nozzles of double shot injection molding machine are separately separated, color of finished products is mostly two-color and is not mixed. The biggest difference between double shot injection molding machine and general injection moulding machine is design of active template of injection unit. In general, double shot injection molding machine has two separate sets of injection units, and general injection moulding machine has only one injection units. Configuration of two sets of injection units has various forms depending on design of each manufacturer. As for design of movable template, rotation mechanism must be provided. Commonly used designs include adding a turntable or a rotating shaft mechanism to provide a 180° reciprocating rotation function to cause mold to alternately move. Other special double shot injection molding do not require a turntable or a rotating shaft mechanism, but are alternately or horizontally rotated by mold.

Two kinds of plastic materials are injection-molded on same injection moulding machine, and molded in two parts, but product only molds once. Generally, this molding process is also called double shot injection molding, usually completed by a set of molds, and requires a special double shot injection molding machine. Two shot molding can make two different characteristics of resin and color into a single two-color product, which can reduce assembly and post-processing of plastic injection molding products, save cost of dissolution and printing, increase aesthetic appearance of product, and enhance grade and added value of product. Not only does it have function of anti-slip and friction, flexible resin material makes it more ergonomic and feels better. Double shot injection molding product has high quality stability, easy product control, short molding cycle and high output, and loss can be 7% lower than that of overmolding. Manufacturing cost of product can be 20%-30% lower than that of overmolding.

With hundreds of global manufacturing partners, we guarantee competitive pricing and unlimited capacity. We can route jobs geographically to reduce lead times, shipping costs, and each order's carbon footprint. Our injection moulding partners undergo strict onboarding. Additionally, we use data to track deliveries, quality and pricing. This ensures your job is always with the most-suited injection moulding parts supplier.

VDI, provides a set of standards for textures and appearances in injection moulding, contributing to improved product aesthetics and performance.

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

The surface finish achieved directly from the injection moulding process, reflecting the natural texture and appearance of the mould without any additional post-processing.

Double shot injection molding not only has function of anti-slip and friction, but flexible resin material makes it more ergonomic and feels better. Quality of double shot injection molding product is high, product deformation is easy to control, molding cycle is short and output is high, loss can be 7% lower than that of overmolding, and manufacturing cost of product can be 20%-30% lower than overmolding.

We have developed proprietary technology and processes that allow you to receive Injection Moulded parts in as little as 8 days. We’re committed to reducing friction and ensuring you are informed at every stage of production.

1. Double shot injection molding machine consists of two sets of plastic injection moulding devices with same structure and specifications. Nozzles are required to have a special structure according to production method, or two sets of molding dies having same structure that can be rotated and transposed. When plasticizing injection, process parameters such as melt temperature, injection pressure and injection melt amount in two sets of plasticizing injection devices are required to be same, and fluctuation of process parameters in two sets of devices should be minimized.

Controlled removal of material using a laser beam to create designs, patterns, or markings on the moulded surface, ensuring precision and permanence.

Aluminium moulds are generally more receptive to modifications and repairs compared to steel moulds. However, significant modifications may require a new mould.

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Custom injection moulding is easily automated and requires minimal operator supervision, making it highly cost-effective and efficient for injection moulding manufacturers.

Precision etching of designs, logos, or information onto the moulded surface using a laser, providing a permanent and high-resolution marking.

From consumer, medical, and energy products to electronics and automotive goods, we’re proud to deliver production-grade injection moulded parts for any and every industry.

Application of specialised coatings to enhance durability, resist scratches, or provide specific properties such as UV resistance or chemical resistance.

Injection moulding offers several advantages, including high production output, cost-effectiveness for large volumes, the ability to create complex designs, a wide range of material options, and minimal waste generation.

Millions of uniform parts can be produced accurately and efficiently through plastic injection moulding services, allowing manufacturers to save time and money throughout production.

Having developed proprietary technology to optimise lead times, we can produce affordable injection moulded parts that can be delivered to you in just 8 days. We provide hard and soft tooling for production or prototype injection moulding and world-class design optimisation. Geomiq has delivered over 12 million injection moulded parts to global customers through our services, providing tool ownership alongside.

Integration of threaded metal inserts during the moulding process to provide durable and secure attachment points for screws, bolts, or other fasteners.

Application of paint or coatings onto the moulded surface using a spray gun, allowing for customisation of colours and finishes.

VDI, provides a set of standards for textures and appearances in injection moulding, contributing to improved product aesthetics and performance.

Injection moulding is compatible with a wide range of materials with different properties and colours, providing endless manufacturing options.

All of our partners’ Injection Moulding technologies allow you to design and produce highly complex parts. We offer medium and fine tolerances down to +/- 0.005mm for production and provide T1 samples for you to approve.

Two plastic materials are not necessarily injection molded on same injection moulding machine, and are molded in two parts; product is taken out from a set of molds, it is placed in another set of molds for second injection moulding. Therefore in general, this molding process is usually completed by two sets of molds without need for a special double shot injection molding machine. Its’ mold has same mold structure as single-shot mold, mainly by adjusting flow rate of injection parameters to control bonding point of seed material. Overmolding is mainly soft plastic rubberize hard plastic. Soft plastic is usually made of artificial rubber, TPU, TPR, etc. Hard plastic can be ABS, PC, PP, etc.

Heated material, typically thermosets and elastomers, is placed into an open mold cavity and compressed under heat and pressure until it takes the mould's shape. This process is widely used for producing large, thick, simple parts with minimal material waste.

4. When two shot molding plastic products are injection-molded, in order to make melt of two different colors can be well welded in mold during molding and to ensure molding quality of plastic injection molding products, higher melt temperatures, mold temperatures, injection pressures, and injection rates should be used.

Double shot injection molding machine is equipped with two barrels. Mold is single-cavity and has common cavity required for the first plastic (“hard plastic”) and second plastic (“soft”). Die and punch required for this technology are single and fundamentally different from the first two production modes. After the first cartridge is injected with the first plastic, the first plastic is partially solidified or solidified. Power cylinder drives isolation blade to retreat to profile of punch. At this time, second barrel is injected with second plastic. After second plastic is completely solidified, injection moulding machine is opened and complete product is taken out. Injection moulding machine is then turned off for next cycle. Obvious advantage of this technology is that it simplifies mold and reduces need for injection moulding machine workspace (a smaller double shot injection molding machine can be used to reduce investment and reduce energy consumption). Moreover, production can be doubled more than “encapsulation method” previously employed, and defective product resulting from re-injection of “hard plastic” which has undergone shrinkage and deformation into cavity is fundamentally avoided.

Since the first and second barrels of “Punch shift” mode are injected in turn, the first and second barrels of “Punch Rotation” mode are simultaneously injected. Therefore, for same product, efficiency produced by “Punch Rotation” mode is twice that produced by “Punch shift” mode.

Precision etching of designs, logos, or information onto the moulded surface using a laser, providing a permanent and high-resolution marking.

We collaborate with 260+ experienced and vetted manufacturers. This allows you to access a world-class supply chain, offering greater capabilities and the highest standards globally, all from a single access point.

The surface finish achieved directly from the injection moulding process, reflecting the natural texture and appearance of the mould without any additional post-processing.

SPI offers standardised textures and gloss levels to enhance the appearance and functionality of injection-moulded products.

2 Double shot injection molding in the form of “Punch Rotation” has two female molds and a convex mold composed of two back-to-back combinations. This punch is rotatable. Two-color injection moulding machines are equipped with two barrels, and second barrel is preferably designed in vertical direction of movement direction of injection moulding machine. Two different plastics can be injected simultaneously. When two plastics injected are solidified, injection moulding machine opens and automatically ejects complete product. After article is removed, “rotatable punch” is rotated through 180 degrees. Injection moulding machine is closed for next cycle.

Plastic injection moulding is the process of creating unique plastic parts by injecting molten plastic into a custom-designed mould cavity. Once the plastic cools and solidifies, it takes on the precise shape of the mould.

Cutting-edge technology for multi-material, multi-shot components. Allows you to mould different materials in a single part.

Reputable providers typically have quality assurance processes in place. They may employ skilled engineers to check files and parts at every stage, from initial quote to final inspection, ensuring high-quality results.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly