Danbar Plastics - The leading regional plastic moulder in ... - injection mouldi

Author:gly Date: 2024-10-15

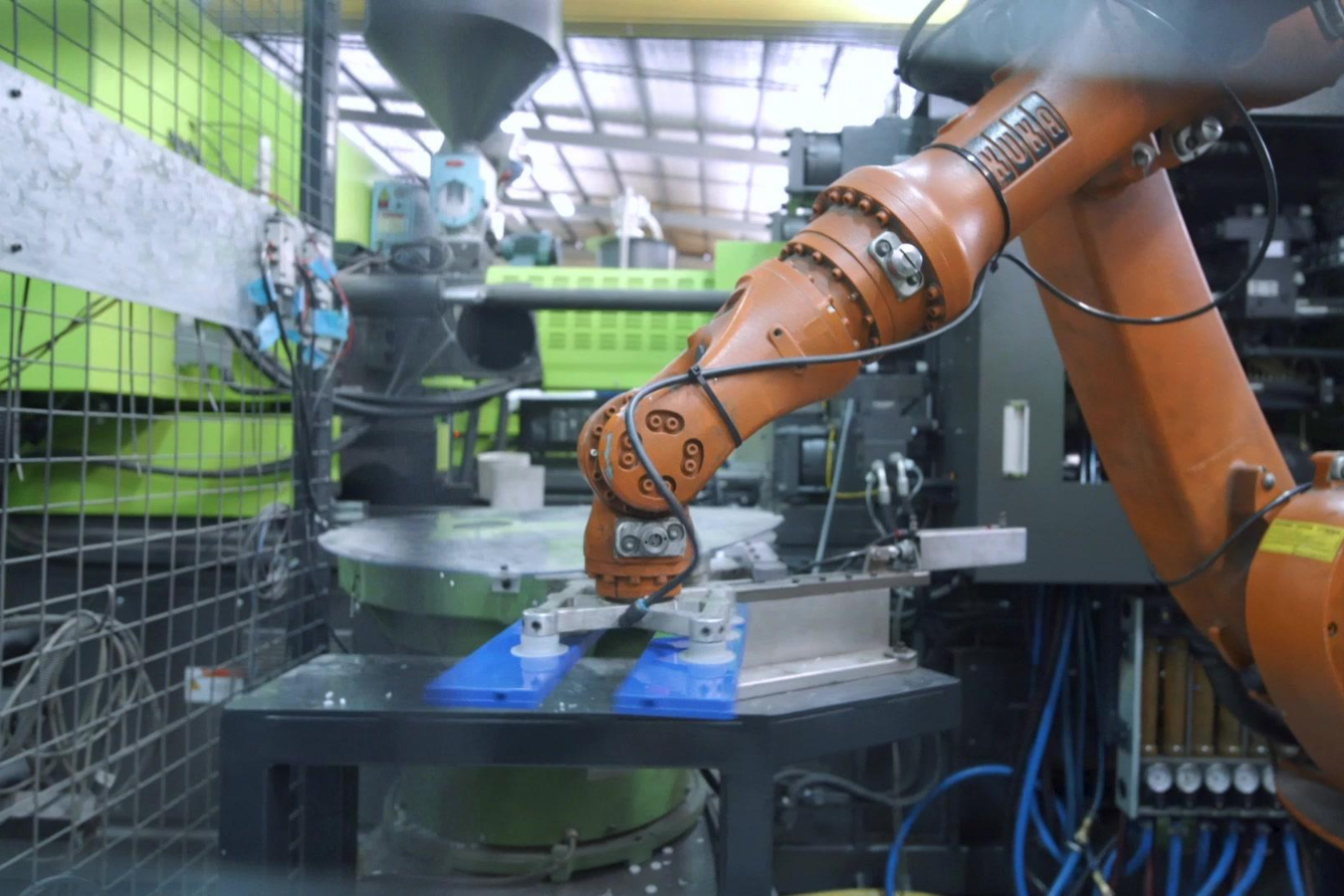

At our core, Evolve is a very proud Australian manufacturer with an amazing team at our award winning advanced manufacturing facility right here in Brisbane. We service numerous industries - from mining to medical, baby products, automotive, building and DIY, and agricultural to name just a few - and we are very proud of that fact. Evolve Group is winning reshoring business every week due our competitive tool and part pricing, lean manufacturing principles along with our robotics and automation services. If you find it difficult to believe we can do it cheaper than China, please contact us for a free quotation or visit us for a tour of the facility. We would love the opportunity to show you.

From OEM parts to custom projects, Retlaw Industries has the capability and resources to deliver impressive results. We work with companies across the nation including within these great states: Colorado, Illinois, Indiana, Michigan, Minnesota, New York, Ohio, Pennsylvania, Washington, Wisconsin, and others!

The chemical properties of acrylic allow it to be completely transparent while remaining hard and highly resistant to scratches and impact. Acrylic can be easily molded into different shapes and sizes, meaning it can be an economic substitute for other types of hard plastic. The professional molding experts at Retlaw Industries can use acrylic material for your specific molded plastic part.

When you choose Evolve Group you choose multiple award winning designers, Australian Made, High Quality Products, Robust Supply Chain, Elimination of FOREX risk, Just In Time Manufacturing, Support of Better Trading Terms, Improved Cashflow, Continual Improvement Support and Future New Product Development Support.

Poly(methyl methacrylate), also known as acrylic, is a clear thermoplastic homopolymer often used as a more resistant alternative to glass. Acrylic is the most common type of clear, moldable plastic available to the general public, and it can be used for anything from windows and picture frames to fake nails and paint.

Highly skilled and trained moulding staff meet the extremely critical tolerances required by customers of both dimension and colour in high or low volumes. All injection moulding plastic resin applications can be processed, including rigid and flexible injection mouldings and products moulded in more demanding engineering grade resins. Gas-assist injection moulding equipment and experience exists to mould components with this technology.

With over 20 injection moulding machines operating 24 hours per day, Evolve Group is able to meet demanding customer lead time requirements. Machine clamp force tonnage ranges from 50 to 1300 tons. All raw material is managed through a centrally feed silo system via an underground drying mechanism into machines to reduce cross contamination and create an optimal product.

Acrylic is one of the most affordable plastics available to the general public. Its impact-resistant structure makes it one of the most useful plastics for a wide variety of applications, including where clear, impact-resistant material is needed. If you want your specific molded plastic part to be manufactured with acrylic resin, contact us for a quote. We'll always make sure your chosen plastic is the best material for the job.

At our core, Evolve is a very proud Australian manufacturer with an amazing team at our award winning advanced manufacturing facility in Brisbane. We service numerous industries - from mining to medical, baby products, automotive, building and DIY, and agricultural to name just a few - and we are very proud of that fact. Not only do we manufacture these high quality products, but in almost every case we have assisted with the design and continual improvement of them.

When you need professionally-manufactured plastic idler pulleys, sprockets, rebar chairs, or custom-made parts made for your business, Retlaw Industries can help. Our certified plastic part manufacturers build OEM parts to your exact specifications. Whether you want acrylic or any other type of composite plastic for your custom part, Retlaw has the capabilities to ensure you succeed.

As with any plastic material, there are some common issues that could potentially arise in the PMMA thermoplastic molding process. Some of the problems that could occur include:

ISO9001 Quality systems are in place to ensure moulded products are produced to documented customer requirements. QA testing and monitoring of product quality is undertaken throughout production with constant quality auditing to ensure the highest standards are met.

Phone: (07) 3803 6222 // 15 Titanium Court, Crestmead, QLD. 4132, AustraliaBusiness Hours Monday-Friday: 8:30am - 4:30pm

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly