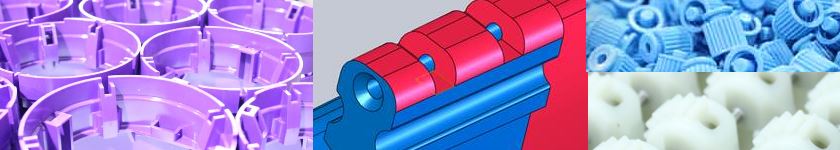

Common Items Made Using Plastic Injection Moulding - injection moulding products

Author:gly Date: 2024-10-15

Our mold maintenance plans for projects that include Thermoplastic Polyurethane injection molding services ensure each mold undergoes regular cleaning and review at predefined intervals based upon the number of setups and cycles. Mold inspections, general mold maintenance, major mold maintenance and preventative maintenance are standard operating procedures.

The production molds for Thermoplastic Polyurethane injection molding projects include high cavitation SPI Class 101 and 102 molds constructed from hardened steel. Cold, runner, hot sprue, and hot runner molds are designed with up to 128 cavities.

We have developed hundreds of products, some with thermoplastic polyurethane injection molding, and manufactured millions of parts annually for the medical industry. Medical devices include point of care diagnostics, microfluidics, and pharmaceutical drug delivery applications.

Our thermoplastic polyurethane injection molding product finishing capabilities include hot stamping, banding, pad printing, silk screening, flaw coating, conductive painting, cosmetic painting, metalizing, and plating.

Our thermoplastic polyurethane injection molding assembly and joining capabilities include product filling, foil/heat sealing, ultrasonic welding, heat staking, mechanical assembly, pinning & UV/hot melt gluing, custom packaging/kitting, and pouching.

Our precision injection molding options include scientific molding, R&D molding, high-cavitation molding, micro molding, over molding, and insert molding.

For the consumer thermoplastic polyurethane injection molding market we specialize in the automated production of high-volume disposables, unit-dose packaging, caps and closures, and over-the counter diagnostics and drug delivery applications.

Natech’s projects that include Thermoplastic Polyurethane injection molding services are supported by MoldFlow Analysis, a Viscosity Curve, a Cavity Balance Study, a Pressure Window Characterization, a Gate Seal Time Study, and a Cooling Time Study. Natech engineers are masters of insert configuration and design single-cavity R&D molds with steel inserted areas. Interchangeable plates, inserts, and sub-inserts allow for more rapid design iterations at LOWER cost than creating new molds for each feature variation. SPI Class 103 and 104 molds are constructed from P20 steel and aluminum with hot runners and cold runners.

Clients trust Natech to be the Thermoplastic Polyurethane injection molding experts in engineering and manufacturing. Our engineers’ experience includes mold qualifications in medical IQ/OQ/PQ, high volume automation in consumer packaging, and engineering-grade resins and ultra-polymers in electronics.

In the electronics market, including thermoplastic polyurethane injection molding, we draw upon deep experience in comprehensive analysis and testing for evaluation and verification to design and build lighter, more durable electronics components.

© Industrial Plasters Ltd. 2022. All rights reserved. Telephone: +44 (0) 1380 850616 Email: info@industrialplasters.com Registered Address: 63 Netherstreet | Bromham | CHIPPENHAM | Wiltshire | SN15 2DP

We take pride in the workmanship of our Thermoplastic Polyurethane injection molding services. All Natech tools and production parts are made in the USA. We run three shifts per day, five days per week, and weekends are run on an as-needed basis.

Each development project requiring Thermoplastic Polyurethane injection molding services is managed by a Project Engineer who monitors and controls deliverables and provides regular status updates.

Our mid to high-volume thermoplastic polyurethane injection molding automated and semi-automated manufacturing of plastic injection-molded components and assemblies for single-use, metered-dose, and multi-use disposables for the drug delivery, consumer packaging and diagnostics industries offer high quality at economical value.

With a long, established history of reliability and expertise we have become the UK’s go-to supplier of casting plasters and associated industries.

We are an ISO-certified, family-owned provider of engineering, custom injection molding, and contract manufacturing. Our clients bring demanding applications requiring Thermoplastic Polyurethane injection molding services and best served by expert engineers.

© Industrial Plasters Ltd. 2022. All rights reserved. Telephone: +44 (0) 1380 850616 Email: info@industrialplasters.com Registered Address: 63 Netherstreet | Bromham | CHIPPENHAM | Wiltshire | SN15 2DP

We provide Thermoplastic Polyurethane injection molding services in New York, New Jersey, Connecticut, Pennsylvania, Florida, California, Illinois, Oregon, Maryland, Massachusetts, Colorado, and Michigan and other regions.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly