Closed-cell EVA foam material for molding products - injection molded foam

Author:gly Date: 2024-10-15

The molding temperature needs to be high when the injected molded ABS parts contain high gloss and ensure not to damage the material in the process. Thus, the temperature for ABS plastic is higher than other injection molding materials.

During the product design process, the principle of uniform wall thickness must be followed. If it is impossible to maintain a uniform wall thickness, please change the mold design in a timely manner. Increase the number of runners or ribs in the area where the feeding is difficult, so as to avoid the defect of underfill caused by too-thin wall thickness.

(2) Oversupply of plastic – If too much plastic enters the barrel, the injection pressure is lost due to the compression of the pellets, thus reducing the pressure required to inject the melt from the nozzle, which is necessary for injection molding, resulting in insufficient injection pressure. The solution is to adjust the amount of feed, i.e., the amount of melt, and make the amount just right for the molding.

The next factor that your manufacturer should ensure is the injection molding speed. If the injection molding speed is high, it can cause burning or thermal decomposition of the plastic material. It can also cause poor glossiness, discoloration and weld lines in the plastic material.

ABS Plastic can be applied to a wide array of products but it is particularly used when the project details require rigidity and durability from a product while ensuring that it is lightweight as well. Some of its popular applications include home appliances, musical instruments, computer parts and more.

ABS Plastic is one of the most popular material choices in injection molding. It is an amorphous thermoplastic widely used in manufacturing through injection molding techniques.

The wall thickness also determines the radius size, thus, it should be ensured by the manufacturer that the ratio of the radius to the wall thickness is not less than 0.3. You should also avoid using an excessively large radius as shrinkage of the resin can occur when the radius is too big.

ABS Plastic can be processed on almost every standard machinery. It can be injection-molded or blow-molded and since it has a low melting temperature (approximately 200°C or 392°F), it’s suitable for processing by 3D printing on an FDM machine. Thus, ABS plastic can be used in a wide array of applications.

Thus, ABS plastic does not undergo degradation. They instead become liquid, so they can be easily injection molded. This property also allows it to be recycled. Thermoplastic liquefies when it reaches a certain temperature level. In the case of ABS plastic, this temperature is 105°C / 221°F. ABS plastic thus, remains rigid and tough even at low temperatures.

ABS Plastic is available in the form of resins, rods and sheets. We have listed some of the leading suppliers for ABS Plastic:

Short shot refers to incomplete filling of a mold cavity which results in the production of an incomplete part due to the insufficient plastic fluidity. The main causes are the inappropriate injection pressure and speed (including excessive pressure loss caused by resistance), which are mainly affected by the following aspects:

(1) Insufficient injection molding capacity – This is caused by an overestimation of the capacity of the injection molding machine, which may also occur due to insufficient plasticizing capacity or insufficient injection volume. Among them, the insufficient plasticizing capability can be increased by extending the heating time, increasing the screw speed and raising the backpressure. If the injection volume is not high enough, the injection machine with a larger injection capacity can be used to solved the problem.

(1) Poor plastic fluidity – If the plastic material doesn’t feature a great fluidity, it will solidify before reaching the furthest end of the cavity or flowing to the overflow tank, which often results in a short shot.

(3) Poor venting. When filling the cavity, air is trapped to cause counter pressure. When the melt is injected into the cavity, the cavity is often closed by the melt in the very beginning, with air trapped in the unfilled local areas. Also, because the filling speed is too fast, sometimes there is not enough time for the air to be vented through the parting surface but compressed instead, resulting in partial unfilled areas in the cavity, thus short shot in the molded part.

It’s established that ABS Plastic is a popular material choice for injection molding techniques but we must note that it has both advantages as well as disadvantages.

VEM Tooling has the expertise and the team that is required for your ABS plastic injection molding techniques. At VEM Tooling, we offer quick quotes, fast, and dependable service.

ABS Plastic cannot only resist impacts, but it is also resistant to chemicals. It does get easily attacked by polar solvents but apart from that, it is strong and durable.

In case of ABS plastic resins, high injection pressure is necessary due to its viscosity but your manufacturer needs to ensure that even though the injection pressure is high, it’s not excessively high as it can increase friction and cause sticking of the molded parts. These molded parts can be separated but separating the molded parts causes the production cost to increase. It is also essential to ensure that the injection pressure isn’t low as low pressure leads to an increase in mold shrinkage, which results in inferior quality parts.

(2) The flow range of the melt is too long, and the flow resistance is too large – The parts that hinder the flow of the melt include the nozzle, the sprue, the runner, the gate, and the thin walls of a product. The flow resistance of the nozzle can be reduced by increasing the nozzle diameter / temperature, and using a nozzle with a small flow resistance.

On the other hand, if the injection molding speed is too slow, insufficient mold filling will occur which can result in other types of defects in the injection molded part.

(2) Try to evenly mix the recycled material and the raw material. Because the recycled pellets, as well as their density are relatively larger than the raw material, if the mixing is not uniform, the amount of the molten material is easily reduced, resulting in reduced injection volume accordingly.

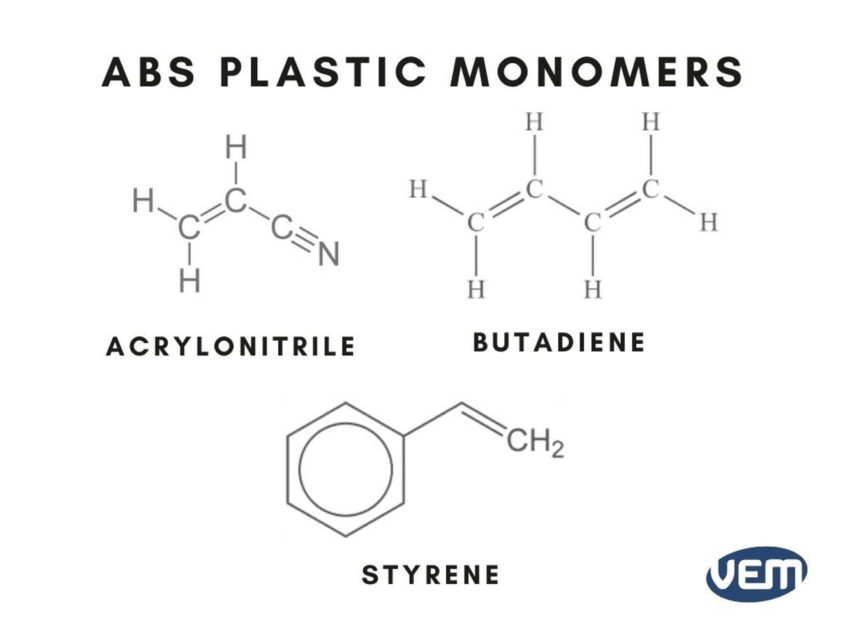

Each of these three monomers has distinct properties and they combine their specific properties into the polymer to create a robust polymer that can resist impacts. Let’s understand more about each of the 3 monomers that combine to form the ABS plastic:

ABS plastic has various grades and is available in fire-retardant, heat-resistant and palatable grades. It is thus considered not only durable but also safe.

ABS plastic pre-treatment: ABS resins in dry form tend to absorb moisture. Thus, it is essential that they are dried prior to processing. It is recommended that ABS resins are treated between 80 to 90°C for at least 2 hours. This pretreatment restricts the moisture content of the resin to less than 0.1%. The moisture absorption rate of ABS plastic is between 0.2% – 0.8%.

It is imperative to ensure that ABS resins are dried before proceeding for processing and manufacturing. This is because dry ABS resins tend to absorb water which can result in various issues. They can lead to increased operating costs and cycles. You must also note that the presence of water often leads to cloudy molded parts.

ABS plastic in its pellet form is melted into a moldable state which is then injected into the cavity of the mold where it forms a part. The molten plastic solidifies as soon as the mold is filled which then cools to take the shape of the mold. Once it has fully cooled, the mold sides open to eject the part. The mold parts are then reset to begin the process again.

Back Pressure: A high back pressure is able to ensure uniform mixing but to avoid wear, back pressure should be as minimum as possible. The expected back pressure is usually 5 bar.

VEM Tooling team encompasses experts that can provide you with ABS injection molding guidance. We ensure that you have a great experience and a seamless manufacturing process from prototype to production. You can contact us to further understand how ABS Injection Molding can be implemented for your project and solve your manufacturing needs.

Overheating ABS resins can lead to thermal decomposition which is why it is essential to ensure optimum injection molding temperature controls. If manufacturers apply excessive heat to the plastic, the chemical bonds will break which often results in brown granules on the injected molded part. This is generally unavoidable if your manufacturer uses old equipment with poor temperature control.

(1) Local short shot caused by the flow imbalance in each cavity of a multi-cavity mold – When the injection molding capacity of the injection molding machine is sufficient, this defect is mainly caused by the uneven flow in each gate, i.e., the mold cavities are not distributed in a balanced way.

Further, let’s understand how ABS plastic reacts to heat and its melting temperature: ABS plastic is a thermoplastic. As opposed to the thermoset plastic materials which allow only one-time heating during the injection molding process, thermoplastics do not burn. They do not undergo degradation through the process of heating to their melting point, cooling and reheating.

The recommended temperature range is between 200 – 238°C / 392°F – 460.4°F. You must also ensure that if the temperature is higher, the resins should not be exposed for a longer time. This will prevent degradation of the ABS resins.

ABS plastic is a low-cost thermoplastic polymer whose properties enable it to be applied to various product designs. Let’s take a look at some of its properties:

(3) Unstable production cycle – Frequent machine shutdown, and production inconsistent with the normal cycle make some plastics stay in the barrel for too long with reduced density and viscosity, thus resulting in plastic underfill.

It’s essential to pay attention to the radius size as it is inversely proportional to the stress and strain on ABS plastic. The more the radius, the less the stress.

As noted above in the properties, ABS plastic material has excellent resistance to stress, chemicals, heat and impact. It also offers a great balance of dimensional stability, tensile strength, and electrical characteristics. All these characteristics make it a strong and durable plastic material.

Standardization and quality are part of our companies core values. We deliver the best possible experience and product to our customers, every single time consistent. Take a look at our certificates!

(1) Improper injection molding process – The low barrel temperature, slow injection speed, short injection time, and insufficient backpressure lead to a shortage of plastic.

This article provides an in-depth analysis of the role of ABS in injection molding. This article encompasses What is ABS plastic? Its properties, its applications and when you should consider ABS plastic for your projects.

All in all, the reasons for short shot are multifaceted, which are also mutually restrictive and mutually influential. To reduce and correct such a defect, we need to make adjustments through an overall consideration of the relationship between these aspects, while making constant practice and accumulating experience continuously to quickly identify the causes of underfill, thereby reducing resource waste and improving product yield.

In order to eliminate such defects, the melt / mold temperature, and the injection pressure / speed can be increased to allow the melt to reach the end of the cavity before solidifying. In such a case, a great plastic fluidity is of particular importance, so selecting the plastic with a better fluidity is also a solution. If the flow coverage is too long and the plastic cannot properly fill the injection molded part, it is recommended to change the gate location to reduce the plastic flow length.

Gate & Vent Design: The gate and vent design needs to be optimally designed according to the plastic. In the case of ABS plastic, following parameters should be paid attention to:

As we have discussed above, ABS plastic is impact and chemical resistant which makes it ideal for a wide array of applications. It is also a popular choice in injection molding techniques because of its low melting point and low cost. It has been thus implemented in various industrial and commercial industries. Let’s take a look at some of the sectors ABS Plastic can be applied to:

If the thickness of the wall isn’t uniform, then the ABS plastic may be under stress which is why the wall of the plastic parts design must be uniformly thick. Your manufacturer can also implement extra ribs or radii to enhance the strength of the mold.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly