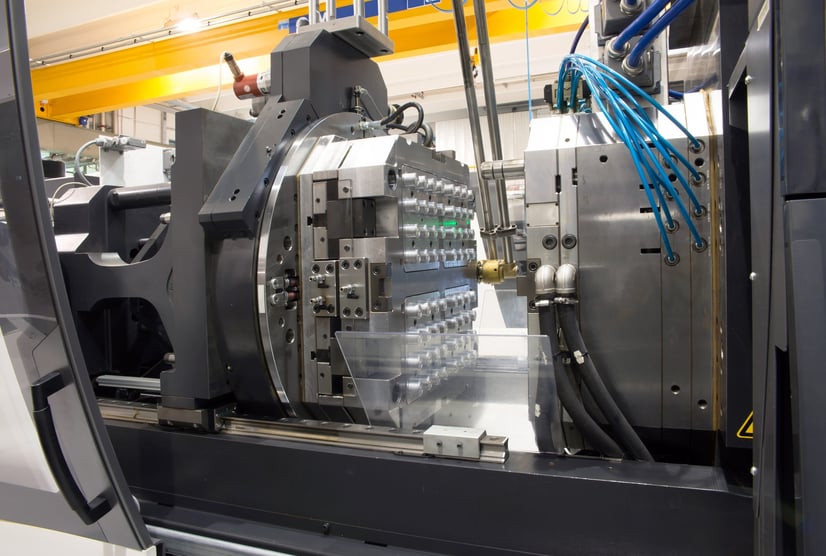

Clean room injection molding - clean room injection molding

Author:gly Date: 2024-10-15

Thicker gates, such as edge gates, aid in the processing and bonding of the overmold. Centrally located gates that take into account the flow length are equally important for complete filling and bond strength. The material flow path is also a factor, so that no features from the substrate inhibit the flow. If such features exist, then additional gates are required. Thick and centrally located gates may leave a gate vestige in an undesirable location on the part, but there are ways and design features that can hide the gating away from view.

At Fictiv, a subset of our highly vetted network of manufacturing partners with proven track records of overmolding success are eligible to take on your overmolding projects. Additionally, Fictiv’s Supplier Quality Engineers (SQE’s) provide oversight for sampling and production to ensure your overmolded parts are of the highest quality.

In thermoplastic injection molding, plastic material is melted and injected into a mold to create a part. Once this part cools, the mold opens and the part drops out.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

Fictiv is your operating system for custom manufacturing. We make sourcing quality, custom mechanical parts simple using our online platform, guided expertise and highly-vetted partner network. For your next injection molding project, create an account and upload your designs to www.fictiv.com to discover the benefits of our design review process for yourself!

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

The most commonly used plastic grades for substrates include PC/ABS, ABS, Nylon and PBT. Generally, TPE, TPU or silicone rubber are most suitable for overmolding. Some plastics, such as POM, PP, HDPE or PEEK are ill-suited for overmolding due to their chemical composition, which prevents a bond from forming between the substrate and overmold. It’s also important to choose a substrate material with a higher melt temperature than the overmolding material so the substrate isn’t melted by the overmolding shot.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Materials choice is the first and most important consideration in any overmolding project because selecting compatible grades can create a chemical bond between the two materials. If they’re compatible, the rubber-like material basically fuses to the plastic, like glue, to create a strong bond.

Below, we’ve broken down how thermosets and thermoplastics differ in the injection molding process, material availability, uses, cost, and recyclability. Take a look:

Fictiv DFM review support: Fictiv’s dedicated DFM engineers and Technical Applications Engineers (TAE’s) are here to support you with your part and tooling design, so that your gates, ejector pins, parting lines and flow length are dialed in — check out our new DFM feedback portal!

We are experts in custom thermoplastic injection molding, and we are happy to answer them for you. Drop us a line, and let’s discuss.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

In recent years, TPE, TPU and material manufacturers have focused on specially formulated materials that bond with various grades of plastic — they’re a great source of materials guidance.

Surface finish can help or hinder overmolding. For example, it’s preferable to to texture the overmolding locations, because a polished surface can cause the rubber to stick to the tool after molding. Texture applied to the substrate on the contact surfaces between the substrate and overmold can help with the material bonding, plus these surfaces are hidden under the overmolding features.

Thermosets, on the other hand, cannot be remelted—so while thermoplastic parts could, hypothetically, be ground up and used in a sandbag, their recyclability factor is limited.

This article will focus on the second application, and we’ll discuss the considerations and guidelines you need to know to ensure success for your next overmolding project.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Thermoplastics are created by melting pellets and then cooling them, which ensures the finished part can also be remelted. This allows thermoplastics to be recycled. Of course, certain properties are no longer the same once you’ve melted a part down, so recycling a thermoplastic doesn’t ensure you’ll get the same quality plastic part—but it is worth noting.

The properties of thermosets and thermoplastics are quite different—but the similarities and differences are often asked about. The primary difference in these two plastics comes down to heat and chemical resistance. Heat resistance is the primary function of a thermoset material, while thermoplastics—which are much more common—can only withstand heat to a certain degree. It’s worth noting that plastic injection molding companies typically do either thermoset or thermoplastic injection molding, but rarely do they handle both.

The very first plastic materials created were thermosets, but today, thermoset injection molding is not as common except with electrical contact applications and liquid silicone. Thus, thermoset injection molders are typically more difficult to find than thermoplastic injection molders.

Insert overmolding (also known as “pick and place” overmolding) is where a substrate is placed into a mold and the overmolding material is injected over the substrate — this method is most commonly used by Fictiv. Insert overmolding requires two separate molds, one for the substrate and another for the overmold.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Thermoplastic parts are more likely to be used for consumer plastics that either won’t come in contact with high temperatures, like the plastic used in milk jugs, or will need to withstand moderately high temperatures. Certain polycarbonates, for example, are resistant to hot liquids and often used to make plastic to-go mugs—but they can still deform or melt at high-enough temperatures.

Overmolding in injection molding is a process that combines multiple materials together to form one single part. Typically, the first material (the substrate) is covered partially or fully by a second material (the overmold). The two most common applications for overmolding are:

Part processing mainly falls on the responsibility of the molder. However, even if material selection and design are properly covered, overmolding processing requires techniques and abilities beyond what’s needed for standard injection molding. Not every molding factory is capable (or willing) to accommodate overmolding products.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

Uniform wall thickness is important for both substrate and overmolding features. Dimensional consistency is especially important for the substrate in order to minimize deformation and ensure that it can be inserted into the overmolding tool properly. Generous draft is also preferable for both shots as rubber-like materials have a higher tendency to stick in the tooling. It’s also important to have shutoff features on the substrate to avoid flash and create crisp lines for the overmolding. And mechanical features such as interlocks can further improve the bond strength — several examples are shown below.

Gating, ejector pin locations, parting lines, and flow length are often an afterthought, but getting them wrong can reduce part performance or adversely affect the overall aesthetic.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Two-shot overmolding is also known as multi-material or 2K overmolding. (Fun fact — 2K comes from the German “zwei komponeten” meaning two components). These injection molding presses are equipped with two barrels, as opposed to the standard single barrel, and can mold two different materials at once. A single tool is needed in this method, though the tooling is relatively complex and more expensive than insert overmolding. That’s why it’s best suited for higher production quantities, where the unit cost is the main consideration.

Using overmolding to create these features consolidates the number of individual parts and eliminates assembly and secondary operations in order to produce a seamlessly integrated product.

Accelerate development with instant quotes, expert DFM, and automated production updates.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Create high quality custom mechanicals with precision and accuracy.

Access a wide breadth of capabilities through our highly vetted network.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

The two main types of overmolding are insert overmolding and two-shot overmolding. Factors such as part design, tooling lead time, and production quantities largely determine which method is most suitable.

Our trained employees ensure your parts will be delivered on time and to spec.

Thermosets are most frequently used in situations where the part must be able to withstand high temperatures. Medical parts are a good example; dental tools with silicone handles and metal parts must be able to withstand the autoclaving process in order to be sanitized and reused over and over again, so the silicone must be thermoset. Higher voltage electrical applications also use thermosets.

In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. This process cures the part so it can never be melted again.

When considering thermoset vs. thermoplastic parts, you’ll also want to consider whether the part will regularly be contact with certain chemistries. If you’re manufacturing plastic casing for an EKG, for example, the material used will need to be able to withstand any hospital-grade chemical disinfectants.

The cost difference between thermoset and thermoplastic injection molding is not black and white. While the thermoset process is typically slower—which equates to a higher cost—the material difference in thermoplastic could range from 90 cents to $10 per pound, depending on the properties. That said, cost considerations should not be enough to sway an engineer toward one type or another—a decision should be based far more on material properties and the functionality of the part needed.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly