China Plastic Injection Mould & Plastic Cap Mould factories - plastic cap mould

Author:gly Date: 2024-10-15

Also known as plastic injection molding, plastic molding is a manufacturing process that makes use of various types of molten plastic materials such as acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PET), high-impact polystyrene (HIPS), thermoplastic elastomer (TPE), polycarbonate (PC), polypropylene copolymer (PPC), polyvinyl chloride (PVC), low-density polyethylene (LDPE), and high-density polyethylene (HDPE). The process calls for injecting molten plastic material into a mold under extreme pressure. This process allows the plastic to take the mold's shape and solidify with minimal defects, if any. This process is a cost-effective solution offering flexible options to brand owners with the ability to produce high volumes of products with complex geometries.

Our passion for continuous improvement is exemplified in everything we do. Our experienced team is devoted to providing high quality parts and personalized service for the companies we serve.

The popularity of the injection molding manufacturing process goes beyond rapid cycle times, precision, and production efficiency. It offers versatility in design, allowing brand owners to add intricate details to the products they envision. You can include complex shapes, branding images, symbols, and precise dimensions in your design. This process also provides excellent material utilization, which minimizes waste and reduces production costs. In addition, it allows you to select various materials to determine which one works best for your intended application. Injection molding allows for repeatable results, enhancing manufactured products' reliability while ensuring all branding features.

Original spare parts - New and used molding machines - Bosch Rexroth pumps - Denison Vickers pumps - Overhaul and repair of hydraulic motors - Energy saving - Molding machines on offer - Servo-Hydraulic solutions - Technical assistance - Pumps and motors overhaul - Hydraulic motors - Danfoss hydraulic motors

Injection molding is widely utilized across various industries and is widely known as an efficient and versatile manufacturing process. Automotive manufacturers employ this technology to manufacture various car components, including bumpers, dashboards, and interior trims. It is well-utilized in the consumer goods sector for producing toys, containers, packaging, and household appliances. The medical industry uses injection-molded products, including vials, syringes, and various medical instruments. All Plastics serves multiple industries, from medical fields to industrial companies.

Intercepting the European market request for increasingly performing, precise and low energy consumption machines, Haitian developed the Zhafir line.

Thanks to their reliability and low cost, these electric machines, designed and assembled at Ebermannsdorf’s German headquarters, have become in 15 years the best-selling category product on the European market.

Its strengths are the 5-point toggle clamping system and KEB’s inverter controlled gear pump servo-assisted hydraulic system (assembled on over 160,000 machines).

Injection mold manufacturers play a crucial role in many industries in the United States. They serve various sectors, including consumer goods, medical, electronics, automotive, industrial, packaging, and medical companies. These manufacturers use state-of-the-art machinery and software to engineer and design molds and products that meet the specific requirements of their clients. At All Plastics, our consistent and robust processes can increase production performance, extend asset life, and provide documentation and component traceability.

A top-rated injection molding company is a highly regarded plastic injection molding industry organization known for its exceptional expertise. This organization has established a reputation for delivering authentic, high-quality products and parts that meet and exceed client expectations. They have consistently manufactured products and components that meet their industry's stringent qualifications and standards. Not only do they employ technically skilled professionals, but they also have state-of-the-art facilities and utilize the latest technologies. Their teams can efficiently execute the various molding processes and use advanced precision techniques. Their commitment to innovation, product quality, and customer satisfaction makes them the preferred injection molding manufacturer, setting them apart from their competitors.

Developed to facilitate the transition between hydraulic and electric machines, Zeres is the optimal solution for hydraulic jack molds; unlike the fully electric machine, it does not need the external unit to control the hydraulic radials.

Our technical team provides complete plastic injection molding and assembly solutions to customers who demand quality and on-time delivery. This efficiency translates into consistent precise componentry and time savings for our customers.

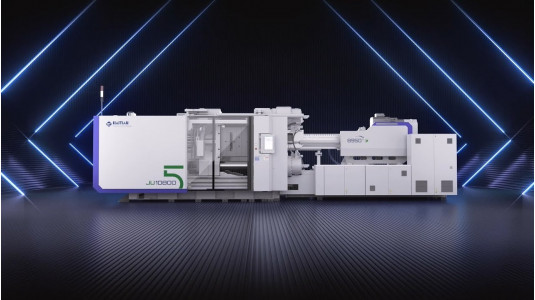

Jupiter, with its range of proposals from 4500 kN to 66,000 kN, is a two-platen machine: in addition to the generous opening strokes, there is an ease of molds’ tooling and an unbelievable space-saving design. Equipped with a pumps’ inverter driver, it guarantees significant energy savings which, combined with molding precision, satisfies the request of many printers, especially with large plastic products.

All-Plastics focuses on markets that align with over half a century of experience and dependable service. Our scientific molding techniques make us a great partner with markets who require precision injection molding solutions, on-time delivery, traceability and consistent quality.

The latest addition is Jenius Series the new hybrid solution with electrical injection combined with space saving two platen clamping unit.

Haitian offers a wide selection of products, ranging from hydraulic, hybrid and electric machines up to large two-platen presses.

The close partnership with IMG, official Italian distributor of the Haitian brand, has created throughout the years a significant synergy to satisfy even the most demanding market requests.

A plastic molding or injection molding company is a manufacturer that specializes in the use of the molding process to produce plastic products. This company applies various techniques, such as RJG eDART Quality Molding and Decoupled Molding, which optimizes performance and efficiency while improving the consistency and quality of manufactured products. An experienced injection molding company, such as All Plastics, can offer various services and solutions, including injection molding, prototyping, tool building, precision molding, and producing quality injection molding parts. We offer these services to companies in various markets, sectors, and industries, including pharmaceuticals, medical, industrial, and packaging.

Selecting the injection molding company best suited for your business requires careful consideration. Assess the company's track record and performance to ensure they can manufacture high-quality plastic products and parts. They need to be certified and able to verify their engineering plastic expertise, demonstrating proficiencies in industrial technology, mechanical design, manufacturing, and prototyping. Next, evaluate the company's manufacturing capabilities, including the production volumes it can handle. Look into the types of materials they can work with to ensure that they can manufacture the product you're designing. Ensure they have systems for advanced diagnostics and sophisticated manufacturing equipment, including temperature and cavity sensors.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly