Alternatives to Injection Moulding for Small Runs - affordable injection molding

Author:gly Date: 2024-10-15

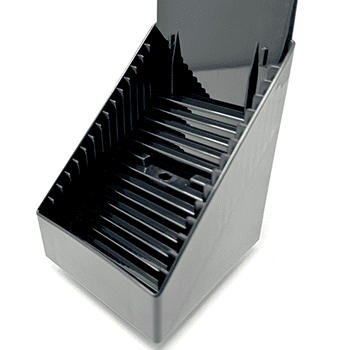

Custom plastic molding provides a solution for businesses in need of custom designed and manufactured parts. We offer a cost-effective solution that provides durable parts designed to perfectly suit your business’s requirements. Custom molded plastic parts can be virtually any shape or size. Anything from bottle caps to parts for a toy can be created through a variety of plastic molding processes.

IPS takes pride in high customer satisfaction through competitive custom molded plastics services, which we offer at a fraction of the cost of other custom molded plastic manufacturers.

Uniform wall thickness means that all the walls of a part are of the same thickness. There are many manufacturing advantages to keeping your part’s wall thickness uniform throughout. One such advantage is that uniform wall thickness promotes consistency part-to-part, which decreases the time required to mold each part for both high and low-volume injection molding production runs. Uniform wall thickness also prevents errors upfront that could waste time and resources, improves a part’s stress distribution, uses less material to decrease costs, and minimizes shrinking post-production.

The importance of uniform wall thickness cannot be overstated, especially when it comes to injection molded parts. By making sure that your part has uniform walls throughout, you can promote streamlined production runs that produce consistent components. Uniform wall thickness can also prevent cosmetic and performance issues, which lengthens the lifespan of each individual part.

Being diligent about enforcing uniform wall thickness can help prevent these complications and other defects from arising before, during, and after a part’s production cycle.

If you take apart a well-made plastic component, you’ll notice the walls are uniform all around. Maintaining a uniform wall thickness is one of the most important rules of injection molding design, and it can determine the success or failure of a part. What is uniform wall thickness, and why is it so important for production? Let’s dive into it.

Thicker walls bring mechanical strength to the table, but thinner walls have a wider range of benefits. Thinner walls use less material, cost less, and are quicker to manufacture. Thin, uniform walls are also more resistant to warping during cooling and take less time to cool. This further increases the efficiency of your production run. After production, components with thinner walls are easier and less expensive to manage, handle, and ship because they are physically lighter.

Don’t see what you are looking for on the list. Browse our list of industries or contact us directly to see if IPS has the solution you are looking for. The list does not stop here. Our team of experts are capable of producing a wide range of custom products to suit your business needs. Whether you are looking for a single plastic part, or a fully assembled finished product with multiple plastic and other parts, IPS can help.

Before you make sure all of your part’s walls are even, you have to determine the proper wall thickness for the part. Finding the best wall thickness can be tricky — your walls must be thick enough to support the intended load of a part without compromising the production and final functionality of your component. Here are some good rules of thumb:

Custom injection molding is a manufacturing process in which molten polymer is injected into a custom cavity (or mold). The polymer then solidifies when cooled, created a customized part. There are endless uses for custom injection molding, while each use may require a different process. Our team of plastic molding experts can help you determine which process is the best solution for what you are looking for.

Price for custom molded plastics varies depending on the type of plastics you need made. This is a cost-effective solution for many businesses looking for customized packaging, parts for a product, and more. IPS provides custom molded plastics at competitive pricing compared to other plastic molding manufacturers and we guarantee the mold for life. If it breaks or needs servicing, we handle that at no cost to our clients.

It’s important to ensure uniform wall thickness when injection molding, not only to promote better parts and more streamlined production. There are a whole host of issues that can occur if your walls aren’t uniform:

Partner with experienced manufacturers in Asia who understand your vision, ensure quality control, and safeguard your intellectual property—these are the keys to transforming your idea into a successful product.

We specialize in producing many different types of molded plastics using specialized processes that include but are not limited to:

Businesses across multiple industries benefit from our custom molded plastics services. Contact our team if you think custom molded plastics might be the right solution for your business.

IPS’ services are easy. First, contact us with the products or services you are looking for. You will be put in contact with our team experienced with all plastic molding solutions. From there, we can help you determine which services that we offer are the right fit for your business. IPS offers a wide range of services from product design to prototyping to engineering and manufacturing, creating a one-stop-shop for everything your business needs to get custom products ready to be put into the hands of your customers.

Some industries that frequently use plastic injection molding services include the food & beverage industry, E-commerce, retail, and packaging. The sky is the limit when it comes to product solutions created using plastic molding. Our partnerships in Asia allow us to develop and produce custom molded plastics at a fraction of the cost of domestic U.S. made parts, with an unsurpassed quality level. We manufacture our own tooling custom which saves our customers thousands. We can design and tool your part from scratch and we guarantee the tooling for life which means we take care of tooling maintenance and replacement if necessary.

At SyBridge, we can help you ensure uniform wall thickness and avoid injection molding design mistakes. Starting with design and material selection, moving all the way to production and post-production processes, our team of experienced manufacturers can help you improve operations and reduce costs. To get started on building uniform and high-quality components, contact us today.

International Product Solutions offers a wide range of plastic product manufacturing, from cost-effective single components to complex multi-part assemblies, utilizing various plastic materials. Through our partner factories, we produce high-quality production tooling at a significantly reduced cost, passing the savings directly to our clients. We provide a lifetime quality guarantee on all tooling, ensuring any necessary repairs or replacements are handled at no additional cost. Contact our team if you are looking for a product solution that may require plastic molding services.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly