Venture Plastics Adds Two Nissei Injection Molding Presses - nissei injection mo

Author:gly Date: 2024-09-30

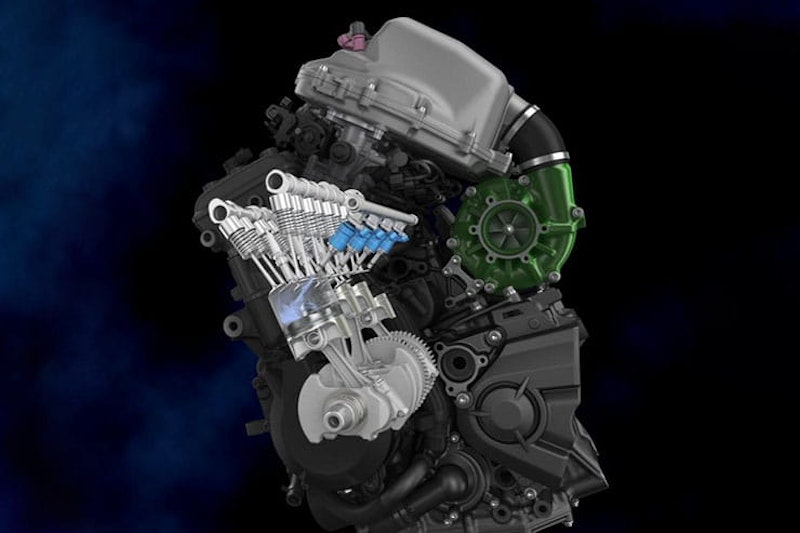

Kawasaki has officially shown its hybrid motorcycle prototype (above) in Japan while announcing plans to electrify its entire range in developed countries by 2035.

Has written for dozens of magazines and websites, including most of the world’s biggest bike titles, as well as dabbling in car and technology journalism.

In August 2009, Wincove Capital acquired GI Plastek. Six years later, Gladstone Investment Corp. acquired Wincove-GIP Acquisition Inc. (d.b.a. GI Plastek) from Wincove Capital.

GI Plastek (Wolfeboro, NH) has merged with Precision Southeast Inc. (Myrtle Beach, SC) to create PSI Molded Plastics Inc. Citizens Bank’s Commercial Banking unit is providing $23 million in credit to help fund the merger.

To convert a petrol engine to hydrogen power, direct injection is vital as the gas needs to be added at high pressure after the cylinder has been filled with air. Forced-induction engines – turbo or supercharged – are also more suited to hydrogen as a fuel than normally-aspirated ones, making the uniquely supercharged H2 engine an ideal starting point for the development project. If successful, the project could lead to a new generation of hydrogen-powered bikes, still using internal combustion engines but with minimal emissions. The main exhaust output would be water vapour.

The hybrid prototype also features an electronically operated gear shift, along with its automated clutches, to allow pushbutton changes and to help smooth the transition between drive sources.

The hybrid prototype, which has been the subject of teaser videos earlier this year and the focus of multiple patent applications, is clearly not a production-ready machine, instead following in the footsteps of the all-electric prototype that Kawasaki showed back in 2019.

GI Plastek is a manufacturer of custom injection molded products using structural foam, gas assist and straight injection molding. It also offers value-added assembly and secondary finishing operations, including painting, inserting and decorating. The company’s press sizes run from 220 to 1,574 tons. In 2016, GI Plastek added two new large tonnage machines with an 1,100- and 500-ton clamping force and installed a new multi-booth mechanized paint line for a total investment of $2 million, according to the company’s website.

As well as the engine, Kawasaki has revealed a design sketch of a future hydrogen bike, looking very much like the Ninja H2 SX sports tourer.

Until she retired in September 2021, Clare Goldsberry reported on the plastics industry for more than 30 years. In addition to the 10,000+ articles she has written, by her own estimation, she is the author of several books, including The Business of Injection Molding: How to succeed as a custom molder and Purchasing Injection Molds: A buyers guide. Goldsberry is a member of the Plastics Pioneers Association. She reflected on her long career in "Time to Say Good-Bye."

The transaction facilitates the merger of two Gladstone Investment Corp. portfolio companies to establish a custom injection molding company with facilities in New Hampshire, South Carolina and Indiana that offer a comprehensive range of plastic injection molding capabilities. The credit agreement was used to pay off existing debt and to consolidate the debt capital in the resulting consolidated entity.

The idea is that the bike can be ridden in pure petrol mode during general use out of town, that it can switch to pure electric power in city centres – allowing it to be used in zero-emissions zones – and both power sources can be used together when maximum performance is needed. A patent filed last year showed how the hybrid system could be integrated with a ‘boost’ button to give an additional kick of power from the electric motor when needed, along with a bar-mounted four-way switch to swap between modes.

Linking in to a patent we reported last year, the initial step to replacing petrol with hydrogen is the development of a dual-injected version of the motor, combining the normal port fuel injection of the standard production bike with a direct fuel injection system that squirts petrol straight into the combustion chamber at incredibly high pressure. This engine was shown at Kawasaki’s presentation in Tokyo alongside the hybrid prototype and the same electric prototype bike that was revealed in 2019.

The merger establishes a custom injection molding company with facilities in New Hampshire, South Carolina and Indiana that offer a comprehensive range of plastic injection molding capabilities.

Bennetts is a trading name of Bennetts Motorcycling Services Limited, registered in England and Wales (company number 11453343) with its registered office at 27 Old Gloucester Street, London, WC1N 3AX. Bennetts Motorcycling Services Limited is authorised and regulated by the Financial Conduct Authority (reg no. 913949). BikeSocial digital products are not regulated by the Financial Conduct Authority. This website uses cookies. Cookies improve the functionality of our website and offer you the best experience. You can delete or block all cookies but some parts of the website will not work. For information including how to stop them, click Cookie Policy.

Precision Southeast Inc., which also has a facility in Indiana, specializes in custom injection molding along with several engineering services, including metal-to-plastic conversions, rapid prototyping and tooling. The company’s press sizes range from 20 to 600 tons. Precision offers overmolding and in-mold assembly and a range of value-add services, such as assembly, ultrasonic welding, leak testing and decorating that includes pad printing and hot stamping.

Although there are still huge stumbling blocks to the adoption of hydrogen as a fuel – not least the problems of supplying it to filling stations, storing it, and finding a safe and reliable way to fill the hydrogen fuel tank on the bike – Kawasaki has shown a keen interest in hydrogen technology across its business. In 2025, the firm’s vast shipbuilding arm intends to make a huge hydrogen-fuelled internal combustion engine for ships, and the firm is also working on projects that should lead to hydrogen-powered jet aircraft in the 2030s.

It appears to use the parallel twin engine from the Ninja 400, allied to an electric motor mounted above the transmission and a 48-volt battery under the rider’s seat. Kawasaki hasn’t announced any technical details, but the firm’s patents have shown that there’s a conventional multi-speed transmission and that an arrangement of clutches mean that either the electric motor or the petrol engine can drive the bike independently, or they can be used together for maximum performance.

The firm says that it will have 10 electric or hybrid bikes in its model range by 2025, and that by 2035 the entire range will be either all-electric or hybrid. However, it’s also working on a hydrogen-fuelled version of the supercharged four-cylinder engine from the H2.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly