Simulating Two-Shot Molding: How Does the First Shot Affect Overall Part

Author:gly Date: 2024-09-30

One notable observation is the prevalence of hydraulic legacy equipment that is still being used by UK manufacturers. The TM Robotics’ injection moulding servicing department has witnessed this first-hand and regularly visits manufacturing sites to service and maintain Shibaura Machine’s own hydraulic injection mould machines — some of which have been in action for up to three decades. On one hand, it is a testament to the resilience of these machines, but the industry must consider the environmental downsides of this ageing equipment.

PharmiWeb.com offers links to other third party websites that may be of interest to our website visitors. The links provided in our website are provided solely for your convenience and may assist you in locating other useful information on the Internet. When you click on these links you will leave the PharmiWeb.com website and will be redirected to another site. These sites are not under the control of PharmiWeb.com.

PharmiWeb.com is Europe's leading industry-sponsored portal for the Pharmaceutical sector, providing the latest jobs, news, features and events listings.The information provided on PharmiWeb.com is designed to support, not replace, the relationship that exists between a patient/site visitor and his/her physician. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

The flagship all-electric range from TM Robotics is the SXIII all-electric series from Shibaura Machine. Shibaura Machine is the new name for Toshiba Machine — the Japanese manufacturer of industrial robots and injection mould machines. The SXIII range boasts faster injection speeds, enhanced sustainability and a streamlined design when compared to its hydraulic predecessors. What’s more, despite the perception of higher costs for all-electric machines, this range can improve cost efficiency by lowering the cost-per-part.

There are over 5,800 companies operating in the UK plastics industry, contributing £25 billion to our economy each year. As a key player in Britain’s manufacturing sector, injection mould shops must embrace technological advancements in injection moulding machinery and accompanying automation for improved profit, productivity and sustainability.

• -To showcase the development of the Plastic Injection Molding for Medical Device industry in different parts of the world.

The most obvious application for robots in mould machine shops is for the loading and unloading of injection mould machines. However, many end users currently have relatively low robotic ability, having traditionally chosen Cartesian X-Y gantry style robots to unload injection moulding machines.

Disclaimer: You are now leaving PharmiWeb.com website and are going to a website that is not operated by us. We are not responsible for the content or availability of linked sites.

Injection moulding applications have long played a key part in the UK’s manufacturing industry, producing everything from medical components, automotive parts, food containers, packaging items and much more. Traditionally, our manufacturers have relied on hydraulic-powered injection moulding machines in their operations. However, the industry is now at a crossroads, faced with the imperative to embrace technological advancements for sustainability and cost-effectiveness.

This was demonstrated by TM Robotics’ customer Lotan, a manufacturer of plastic containers based in Leicestershire, UK. Lotan’s production facility exclusively uses all-electric injection mould machines from Shibaura Machine. The SXIII provides significantly faster injection speeds than traditional moulding equipment, providing 35% faster cycle times than conventional hydraulic servo IMMs.

Another area of debate in the injection moulding world is robot integration. The UK seriously lags behind other developed countries for its number of robot installations. That’s not just for the world of injection moulding, but in the UK manufacturing sphere more widely. In fact, the International Federation of Robotics (IFR) reports that the UK has just 101 robots per 10,000 employees — rookie numbers compared to competitors in the US, China and Germany.

Also, please be aware that the security and privacy policies on these sites may be different than PharmiWeb.com policies, so please read third party privacy and security policies closely.

The injection moulding process is responsible for up to 90 per cent of the Global Warming Potential (GWP) in the entire mould lifecycle. Recognising this, TM Robotics has championed investment in all-electric injection mould machines to replace older, more energy-intensive models.

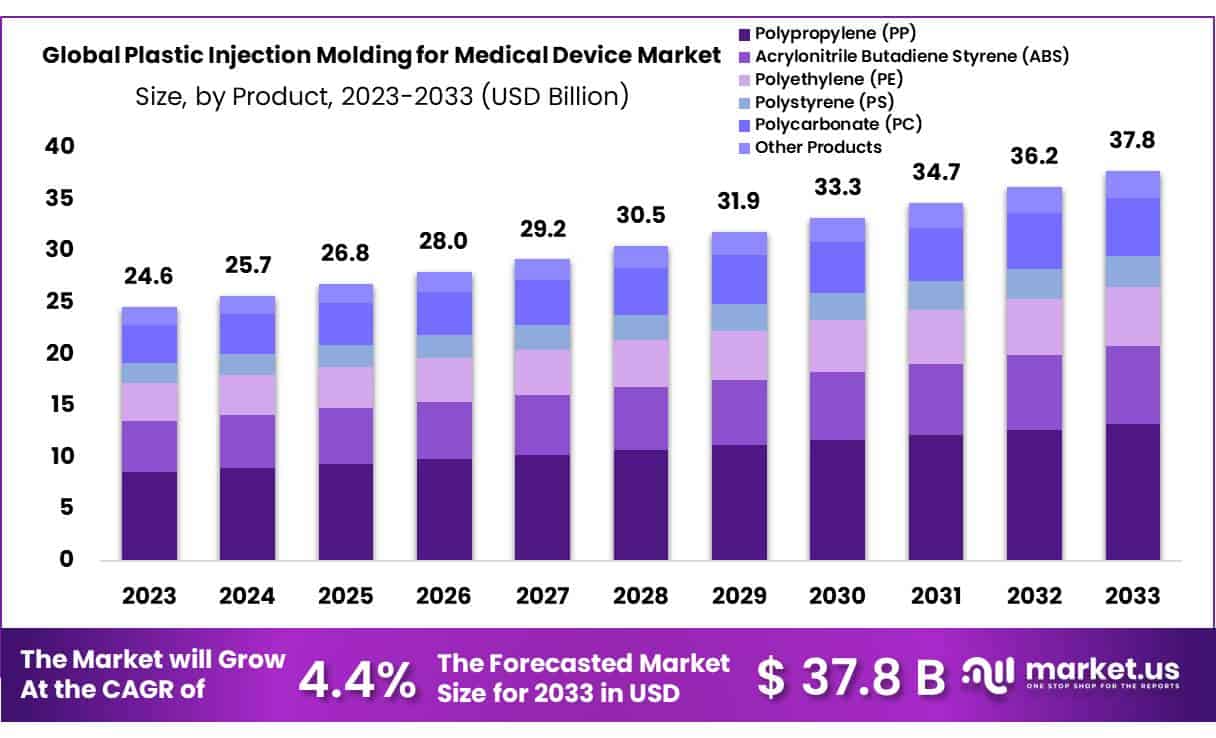

The Plastic Injection Molding for Medical Device market boasts a strong global foundation. The market research report conducts a thorough analysis, forecasting future trends, growth factors, consumption and production volumes, as well as CAGR numbers. Moreover, it offers recommendations, profit margins, and pricing data sourced directly from the market, aiding market participants and individuals in predicting future profitability and making informed business decisions.

The Plastic Injection Molding for Medical Device Market report provides a deeper understanding of the industry. This helps in the development and execution of marketing strategies to better target the market. Market research reports can reduce risk, and save time and money. The Plastic Injection Molding for Medical Device industry report can be used to increase the company’s industry knowledge, develop new marketing and advertising strategies, and identify the right demographics. The Plastic Injection Molding for Medical Device Market Report has the most comprehensive research and the required expertise to ensure and receive the right information. This applies regardless of whether businesses want to analyze existing or emerging markets or find new product trends.

Unlock competitive advantages with our PDF sample report, detailing market trends, drivers, and challenges: https://market.us/report/plastic-injection-molding-for-medical-device-market/request-sample/

The report provides insights into the future needs and potential opportunities of the Plastic Injection Molding for Medical Device market, highlighting key market players and their roles. Utilizing key market dynamics and growth variables, the report calculates market value and growth rates. Drawing from current industry news, market trends, and growth projections, it also presents a detailed analysis of market and competitor scenarios, including a SWOT analysis of prominent competitors.

The Global Plastic Injection Molding for Medical Device Market Report Also Encompasses The Regional Analysis To Offer The Complete Regional Development Status. Additionally, The Report Also Provides Necessary Recommendations And Suggestions For The Plastic Injection Molding for Medical Device Market Players So As To Attain A Competitive Edge In Various Regions. It Also Provides Market Size And Forecast Estimates From the Year 2024 To 2033 About Five Major Regions,

PharmiWeb.com is Europe's leading industry-sponsored portal for the Pharmaceutical sector, providing the latest jobs, news, features and events listings.The information provided on PharmiWeb.com is designed to support, not replace, the relationship that exists between a patient/site visitor and his/her physician.

-To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Plastic Injection Molding for Medical Device market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

To understand how our report can make a difference to your business strategy, Inquire about a brochure at https://market.us/report/plastic-injection-molding-for-medical-device-market/#inquiry

• -To carefully analyze and forecast the size of the Plastic Injection Molding for Medical Device market by value and volume.

If you have any questions or concerns about the products and services offered on linked third party websites, please contact the third party directly.

Unlock competitive advantages with our PDF sample report, detailing market trends, drivers, and challenges: https://market.us/report/plastic-injection-molding-for-medical-device-market/request-sample/

PharmiWeb.com is not responsible for the content of linked third party websites. We are not an agent for these third parties nor do we endorse or guarantee their products. We make no representation or warranty regarding the accuracy of the information contained in the linked sites. We suggest that you always verify the information obtained from linked websites before acting upon this information.

Nigel Smith, managing director of TM Robotics, the international distribution partner of Shibaura Machine and the UK and Ireland distributor of its injection mould machines, explores the changing landscape of plastic's injection moulding sector and argues the case for investment in new technologies, both for better operational efficiency and improved sustainability.

• -To analyze and study micro-markets in terms of their contributions to the Plastic Injection Molding for Medical Device market, their prospects, and individual growth trends.

Due to this lack of uptake, the UK industry is missing some of the potential benefits of industrial robots, including improved productivity, efficiency and throughput. As a primary distributor of Shibaura Machine robots in the UK, the TM Robotics team has spotted opportunities for the injection moulding sector to reap the rewards of robotic automation.

An Increase in Demand and Opportunities for the Global Plastic Injection Molding for Medical Device Market by 2024,” offers a comprehensive analysis of the market by evaluating research and information from multiple sources. This report empowers decision-makers worldwide to positively influence the global economy by providing a detailed overview of the market, including statistics, market size, and competitive conditions.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly