Asahi Kasei Brings Bevy of Automotive Plastics to Fakuma - automotive injection

Author:gly Date: 2024-09-30

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Micro-injection molding requires highest precision in all phases of the injection molding process, including consistency of shot weight. One ongoing commercial molding program involves connectors made of liquid crystalline polymer (LCP) with a shot weight of 0.484 g and an injection time of 0.018 sec. The Engel customer is achieving great results here thanks to the “smart-shut” sliding-ring nonreturn valve: The deviation per shot is a maximum of +/-0.0005 g, which is about 0.1%.

We don’t have a particular R&D section. I wish I had one, but it’s difficult for an SME like us. I’ve changed our approach to be project based. If something interesting comes up, I call some people and say, “let’s do this project together” and see what happens. Even if we don’t achieve our goal we are still able to gather lots of useful information. For example the clic disk for a (compact linear collider of CERN), is an accelerator part. There are only 5 or 6 companies in the world that are qualified to produce these. We like to challenge that. It can be very fun and exciting to join a program like that. We would never be able to have this kind of experience just by making molds, because it’s a scientific project so we can work with actual scientists which is inspiring and enriches our own work. This may help solve all of our energy problems. Maybe not for our generations, but for the future.

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

Maximum precision in the interaction of all units of the system is indispensable here. Engel recommends for this purpose all-electric and tiebarless injection molding machines from its e-motion TL series, not only for development, lab work and prototyping or for short runs, but also for high-volume production (Fig. 2). These precision machines are complemented by a new flexible micro-injection unit (see sidebar) that was developed as a dedicated solution for LSR micro-injection molding.

FIG. 3 The automotive industry is one of the main drivers of the micro trend. This air-intake valve for the massage function in vehicle seats measures 4 × 3 mm and combines LSR and nylon in an overmolding application. (Photo: Sei Woo)

Well, I know how to use the right side of my brain. A lot of people in the business world have a tendency to use the left side, I think, but the right is just as important. It allows me to see certain problems multidimensionally, approach issues from a different angle or perspective and find new creative solutions. I’m a person who can give ideas just by looking at things. I'm not an engineer, and have no experience in a plastic molding factory but I can make decisions and give ideas of how to look at things differently. I’m trying to change the culture for new development in the future. If we can’t make it happen, the future is going to be much more difficult than it needs to be. We don’t need to be huge innovators like Apple, but we can create micro innovations. Kaizen to me, is micro innovation. There’s an expression in Japanese, “if the dust gathers, it becomes like a mountain”. I really believe that small things can build to something much greater.

For example, Engel uses the tiebarless version of the all-electric e-motion TL as the basis for LSR micro-molding. The machine produces tiny silicone components with a new LSR micro-injection unit. However, thanks to a quick coupling system, it can be converted into a thermoplastic injection machine in less than 30 min. And even switching over from micro-injection molding to the production of small components with a size 15 or 18 barrel in the injection unit is possible on the same machine. The material feed required in each case can be smoothly integrated into the machine control system via standardized interfaces (OPC-UA). This turns a standard machine into a highly flexible production unit for small and micro-components made of either LSR or thermoplastic.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Some special features must also be taken into account in handling the tiny parts, the automation on the machine, and quality control. Takeoff by means of a gripper is just as unthinkable as allowing sensitive parts to simply drop off the mold.

Better control of LSR mixing/dosing and cold-runner valve-gate injection, as well as improved mold-design capabilities are highlighted at Molding 2019 Conference.

You became the CEO in 2015 and are the 2nd generation as your father started the company as you told us. In the distant future when you hand over the company to the next generation, what legacy or vision to leave behind to your successor?

My father had a problem when he was maybe 30, 35 years old. He had a dispute with his customers. Who is causing the trouble? The designer, the mold maker, molders, producers? He wanted to find a way to avoid such troubles, almost like an insurance. With our Juken system, when customers call us we can readily access technical information for them about whatever products of ours they may be using. We can then discuss and find solutions that we otherwise may not be able to.

First of all, our defect rate is about 1 ppm (parts per million). We carry 3000 different items every month and our defect rate is extremely low, which is very nice for us, but nice for our customers too. They are much more at ease to accept our products. Some clients don’t even check, they just go directly into their lines. We also try to reduce scrap materials and recycle. We have many ideas about creating our own new product using recycled plastic and making it in house. Reducing costs is also very important. Because in the 1980s and 90s we enjoyed a very great market because we didn’t have many competitors but now reducing costs has become a really big theme for us to stay competitive. For example we have two factories that just merged this year as a cost cutting measure. It’s much easier now to manage manpower and costs. I am expecting to increase our productivity by 10-15%. We also had a groupware server which has been really good for us. We’re also trying to create more opportunities for education, so that people can actually learn here not just by working but by going out for seminars and through our own teaching programs. Because we are so focused on small parts and have been for so long, there is so much more for us to learn about all the different parts of plastic molding as an industry. We’ve also started English courses here and are asking managers to join societies like scientific societies, which has been very effective. We’ve put a lot of effort into our facilities to maintain their condition.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

Juken Kogyo fully leverages its expertise in micro- and nano-precision technologies to produce plastic components, offering micro-gram (one millionth of a gram) gears and nano-machined products through its precision injection molding. Founded in 1965, today many of the company’s plastic parts are used for various products that support the Japanese manufacturing industry, whilst also supplying micro parts to manufacturers all over the world. We speak with president, Naoki Matsuura, to learn more about how Juken Kogyo contributes to key sectors of the economy that require such meticulousness and quality, with precision molding technology, as well as his insight into the plastics manufacturing industry.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

The trend towards miniaturization has gained considerable momentum in recent years. Many products—and with them the parts they are made of—are becoming smaller, more delicately complex and more compact. Micro-injection molding is used to produce many of these complex, delicate parts. In medical technology, examples include the increasing numbers of minimally invasive operations or new methods of analysis. Another target group for micro-molding is consumer electronics with very small electronic and optical precision components for smartphones, among other things.

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

In a time where sustainability is no longer just a buzzword, the food and beverage packaging industry is required to be at the forefront of this innovation. By adopting circular packaging processes and solutions, producers can meet regulatory requirements while also satisfying consumer demand and enhancing brand reputation. Join Husky to learn more about the broader implications of the circular economy — as well as how leading brands are leveraging this opportunity to reduce costs, increase design flexibility and boost product differentiation. Agenda: The cost and operational benefits of embracing circularity Key materials in circular packaging — including rPET and emerging bioplastics How to design a circular food and beverage package Strategies for selecting sustainable closures to future-proof packaging solutions Optimization and streamlining of production processes for enhanced efficiency How Husky Technologies can enable your sustainable success

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

It’s been wonderful. IT technology development has just been wonderful. Combining traditional methods with new technology has been really very good. This way we can pick the best of each to make much better systems and solutions. For example, we do have a physical filing system, but we also have a database. Because many of our products are so small, the corresponding physical file often actually contains the product in question. It’s more than just data. We have been using data for checking or reviewing, but it's time to start using it as prospective tools as well, even for SMEs.

The special features of a tiebarless machine have a positive effect in the injection molding of micro-parts. Due to their design, these machines inherently ensure great platen parallelism and uniform clamp-force distribution. In addition, the tiny parts often need to be produced in a cleanroom. A compact machine design with a large clamping surface reduces the space requirements here; and the clean machine concept without hydraulics, with encapsulated toggle levers and linear guidance, also supports the processor in complying with GMP (FDA’s Good Manufacturing Practice) specifications.

The Engel e-victory injection machine used here has an electric injection unit in combination with a servohydraulic, tiebarless clamp. Since the tiebarless clamp allows for full utilization of the mold platens right up to the edge, even large, bulky molds with a rotary table will fit on a comparatively small machine.

Raw-material supply to the injection molding machine is another point where LSR and thermoplastic micro-injection molding differ. The two components of liquid silicone are stored in containers whose volume should not exceed 0.5 to 0.7 liters for microinjection molding. To additionally protect the material, the hose connections to the barrel also should be as short as possible and have only a narrow cross-section. When selecting the metering pumps for the molding system, Engel gives priority to working with partners whose units are OPC UA-capable in order to ensure integration into the machine control system.

The most important differences in processing result from differences in temperature control for the two kinds of materials up to curing or vulcanization. When injection molding LSR, a two-component composite is mixed at room temperature in the barrel module. Feeding to the barrel takes place along the shortest possible paths with a small cross-section; distribution is then handled by a valve gate and sub-runner. The LSR vulcanizes in the mold at temperatures of 170 to 190 C (338 to 374 F) to form the elastic part. The mold and its temperature control must therefore be designed for high temperatures. Strict thermal separation between the barrel and mold must also be ensured to prevent the premixed liquid-phase LSR from unintentionally vulcanizing in the barrel.

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

The LSR microparts are still very hot on demolding, which must be taken into account when designing the automation system for parts handling. Particular attention must be paid to using heat-resistant materials and measuring technology here.

The Worldfolio provides business, industrial and financial news about global economies, with a focus on understanding them from within.

The sprue channel alone illustrates how much technical know-how micro-injection molding requires. Its volume must be in a balanced ratio to the volume of the molded part(s). Several boundary conditions have to be weighed against each other and the overall process optimized. Key factors are process management, the waste and energy statistics, the material price and cycle time. All this poses the greatest challenges for the equipment manufacturer and for the manufacturer of the micro-parts.

Say “manufacturing automation” and thoughts immediately go to the shop floor and specialized production equipment, robotics and material handling systems. But there is another realm of possible automation — the front office.

Such small quantities as in this example—connecting elements used in instruments for ophthalmic diagnostics—now must be uniformly and repeatably distributed over all the cavities. The micro-injection unit, the sprue channel and thermal management are enormously important here in terms of quality, precision and repeatability.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

A new LSR micro-injection unit, developed jointly by Engel and ACH Solution (both in Austria), makes it possible to manufacture precision parts from LSR with shot weights significantly below 0.1 g. The unit consists of a plunger rather than a screw; but ACH incorporates a dynamic mixer (rather than a more typical static mixer) into the feed system to ensure a good mix of the silicone A and B components and pigment, if any. Technically, it may be considered a two-stage injection system, because there is a hold stage for the mixed liquid components, followed by an injection stage. Plunger diameter is 6 mm and maximum shot capacity is 2.26 cm3. For very tiny components, Engel recommends using this system together with its iQ weight control software.

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Micro-injection molding means working with part weights of significantly less than one gram. Right now, some manufacturers are already achieving part weights below one milligram—although it makes a big difference here whether the raw material is a thermoplastic with a low specific weight or a liquid silicone with higher density (typically 1.10 to 1.50 g/cm3). Micro-parts made of silicone are generally heavier than thermoplastic micro-parts, but they can be smaller—and more challenging—in terms of dimensions.

Without us noticing, tiny plastic parts are increasingly making inroads into our lives: in cars, medical technology, mobile phones and wearables. Increasing numbers of these micro-parts are made of silicone. But what challenges does micro-injection molding pose for processors? Is liquid silicone, which is seeing increasingly widespread use, making processes more complex than they already are for thermoplastics? And where will the journey take us—how far can the limits of what is feasible be pushed?

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

Join this webinar to explore the transformative benefits of retrofitting your existing injection molding machines (IMMs). Engel will guide you through upgrading your equipment to enhance monitoring, control and adaptability — all while integrating digital technologies. You'll learn about the latest trends in IMM retrofitting (including Euromap interfaces and plasticizing retrofits) and discover how to future-proof your machines for a competitive edge. With insights from industry experts, it'll walk you through the decision-making process, ensuring you make informed choices that drive your business forward. Agenda: Maximize the value of your current IMMs through strategic retrofitting Learn how to integrate digital technologies to enhance monitoring and control Explore the benefits of Euromap interfaces and plasticizing retrofits Understand how retrofitting can help meet new product demands and improve adaptability Discover how Engel can support your retrofitting needs, from free consultations to execution

For the market launch of the micro-injection unit at the end of 2020, it was used to mold connecting elements for medical instruments in a valve-gated, cold-runner mold with 32 cavities. The delicate parts measure 1.7 mm long × 0.9 mm diam., with a combined part weight of just 16 mg. The unit runs on an all-electric and tiebarless Engel e-motion 50/30 TL injection molding machine and is supplied by an LSR metering pump from ACH Solution. An Engel viper 6 linear robot removes the parts and deposits them on a conveyor belt for camera-based quality control.

Plastics Technology’s Tech Days is back! Every Tuesday in October, a series of five online presentations will be given by industry supplier around the following topics: Injection Molding — New Technologies, Efficiencies Film Extrusion — New Technologies, Efficiencies Upstream/Downstream Operations Injection Molding — Sustainability Extrusion — Compounding Coming out of NPE2024, PT identified a variety of topics, technologies and trends that are driving and shaping the evolution of plastic products manufacturing — from recycling/recyclability and energy optimization to AI-based process control and automation implementation. PT Tech Days is designed to provide a robust, curated, accessible platform through which plastics professionals can explore these trends, have direct access to subject-matter experts and develop strategies for applying solutions in their operations.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us

FIG. 2 The all-electric and tiebarless Engel e-motion TL injection molding machine is tailored for micro-injection molding. It is offered with a special LSR micro-injection unit jointly developed with ACH Solution and a metering pump system from the same partner.

In the last 25 years we have seen the rise of cheaper competitors such as China, South Korea, and Taiwan replicating the Japanese monozukuri process and doing so at a cheaper labor cost. They have been providing the world with cheaper products at the expense of quality. Yet despite this stiff competition Japan has been able to maintain its leadership as it relates to advanced machining, and niche fields. Can you please tell us about the essence of the Japanese monozukuri? How are companies such as yourselves able to compete internationally despite such stiff competition?

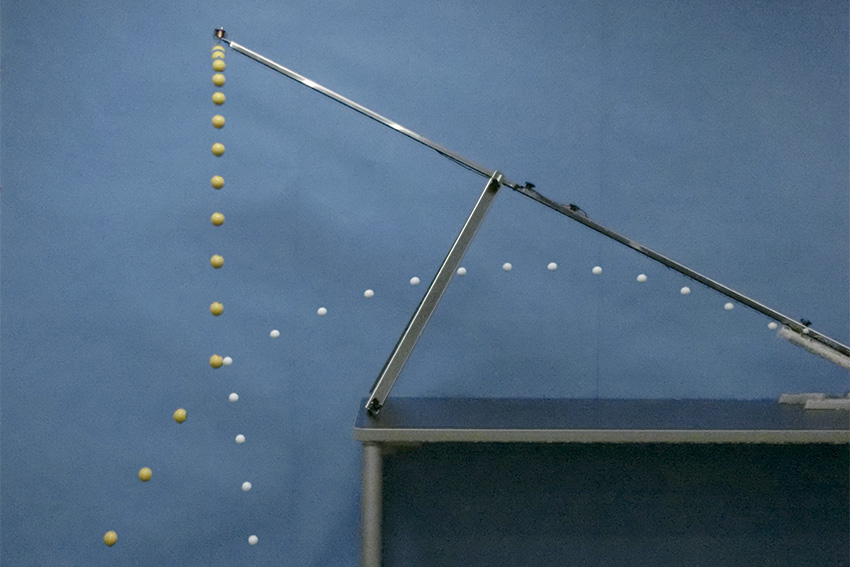

Static charge means that the parts stick to smooth surfaces like magnets and can then hardly be gripped even using your fingers. For this reason, micro-injection molded parts are often taken in by vacuum and blown into a small collection container. Once the parts are in the container, things that are otherwise self-evident, such as counting, measuring or weighing a single part, are no longer possible due to the minimal dimensions. Camera inspection for quality assurance therefore takes place on the way from the cavity to the collection container or even directly at the cavity before part removal. To accomplish this, the camera is located on the gripper, which docks onto a specific position on the mold, allowing the camera to assess the quality for multiple cavities. Engel partners with market leaders in automation and quality assurance and offers turnkey production units from a single source.

But before we turn to the differences between LSR and thermoplastic in processing, it's worth taking a comprehensive look at the special challenges of micro-injection molding. These challenges exist independently of the raw material used, because some of the engineering challenges in micro-injection molding arise solely from the part—and part feature—dimensions and extremely low masses processed.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

FIG. 1 These LSR micro-parts—connecting elements in instruments for ophthalmic diagnostics—measure 1.7 mm long × 0.9 mm diam. and weigh just 0.0005 g each. They’re molded in 32 cavities.

He decided to keep the records for every product, even scribbling them on a piece of paper. It was a great way to leave the process of solution making, not just the end result. When it comes to plastic molding we want to avoid any kind of defect, so even when we are using customer designs we have a library of information of what kind of things have worked and what kind of problems we have encountered in the past.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

Join Wittmann for an engaging webinar on the transformative impact of manufacturing execution systems (MES) in the plastic injection molding industry. Discover how MES enhances production efficiency, quality control and real-time monitoring while also reducing downtime. It will explore the integration of MES with existing systems, emphasizing compliance and traceability for automotive and medical sectors. Learn about the latest advancements in IoT and AI technologies and how they drive innovation and continuous improvement in MES. Agenda: Overview of MES benefits What is MES? Definition, role and brief history Historical perspective and evolution Longevity and analytics Connectivity: importance, standards and integration Advantages of MES: efficiency, real-time data, traceability and cost savings Emerging technologies: IoT and AI in MES

It’s not so much a strategy but more of a vision I’m looking to not just be a parts supplier but to be a unit supplier. I’d like to have an assembly line, actually we’ve already started. We’re making some catheter key parts, and are also assembling handles and things like that. So that’s the direction we’re headed in.

We are now in the 4th industrial revolution and are seeing the rise of new innovative technology such as IoT, AI, and Big Data. As a company that specializes in the IT field, can you please tell us what the impact of these new technologies has been on your company and how you are adapting them to your products?

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

We just started discussion with an American company about a potential international partnership for the production of specimen holders for TEM (trans-electron microscopy). It’s quite an interesting project as the key device of that microscopy can be created with our mold making technology. So we match up with them very well. They luckily have almost the exact kind of machine tools that we’re using. They share many of our views. It’s quite nice to hear American people not just talking about the business performance but also talking about the machine tools, expertise and passion for the work.

Engel offers the “smart-shut” sliding-ring nonreturn valve for very low-viscosity melts (or LSR) and short cycle times to provide support for achieving the greatest possible shot-weight consistency (Fig. 4). The non-return valve is particularly useful in applications with a very short injection stroke and very slow injection speeds. The underlying principle is that valve closing is actively initiated by the counter-rotation of the screw; this means that the nonreturn valve is already completely closed when the injection process begins.

Given a component 1.7 mm long and 0.9 mm in diam., the part weight made of LSR is 0.0005 g (Fig. 1). If you have 32 cavities, the total shot weight (including sprue) is then 0.125 g. This is the equivalent of about 125 grains of sugar. For comparison's sake, a sugar cube contains about 20,000 to 30,000 grains.

The Plastics Industry Association (PLASTICS) has released final figures for NPE2024: The Plastics Show (May 6-10; Orlando) that officially make it the largest ever NPE in several key metrics.

The aim of this presentation is to guide you through the factors and the numbers that will help you determine if a robot is a smart investment for your application. Agenda: Why are you considering automation? What problems are you trying to solve? How and why automation can help Crunch the numbers and determine the ROI

Ing. Leopold Praher, Sales Manager elast/LIM/thermoset for Engel Austria in Schwertberg, has 35 years’ experience in sales and marketing worldwide in the elastomer industry. He has been with Engel since 1988, starting in spare parts and moving to area sales manager for rubber and silicone machines in 1994. He became worldwide sales director for the Elast Dept. in 2000. Contact: leopold.praher@engel.at; engelglobal.com.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Having said this, silicone offers benefits in terms of takeoff and part design: The elastic components can be deformed during demolding without impacting quality. This increases design freedom for LSR micro-parts; even small undercuts are possible here. On the other hand, in the case of thermoplastic parts, a strategy for damage-free removal of the rigid, cooled parts must be carefully considered in advance.

We know that injection molding and 3D printing are standard when it comes to plastic parts but there are some limitations. They cannot go under 20 microns in terms of resolution. To solve this problem we have nano injection molding that allows the creation of nanometer scales such as your company is able to provide, up to 0.5 microns. We know that your company Juken Kogyo provides nanometer ultra precision machinery and also nano technology. Can you please tell us about the synergy you are able to create between the machinery and the technology, and how you are able to provide solutions to your customers when it comes to nano technologies?

We supply intraocular lens molds as well. Intraocular lenses are basically the implanting lens’ for cataract surgery. As my father got old and he started losing his sight he had to change his lens and it changed his life. He came to me and told me, you did a great job. It was great encouragement, a big payoff and a great joy of working. It connects back to your first question, as to how monozukuri feels, the mentality, it’s not just the money, but the value to society you create and the role you can play to serve people. My father’s comment was really fulfilling because we spent 10 years getting into that market and it was very tough. No blueprint, no friends, and were still able to break through.

In 1985 you took your first steps to go overseas. You went to Singapore, China, India, Switzerland, Thailand, Taiwan, S. Korea, I could go on. In our research we found that you expanded through joint ventures. Can you tell us about your international strategy? What benefits have joint ventures brought to your company?

The requirements placed on the production unit therefore initially appear to be fundamentally different, yet they can be met on a single injection molding machine. This offers the processor more flexibility and the opportunity to better utilize its machines. How does it work?

Even luxury goods such as watches increasingly contain tiny components made of thermoplastic—for example, cog wheels in watch movements or clips—and silicone for tiny seals. It is the latter material, in particular, that is gaining increasing market share because of its special properties. Due to trends toward electromobility and autonomous driving, the automotive industry will also require larger numbers of micro-parts made of liquid silicone rubber (LSR) in the future.

Join Engel in exploring the future of battery molding technology. Discover advancements in thermoplastic composites for battery housings, innovative automation solutions and the latest in large-tonnage equipment designed for e-mobility — all with a focus on cost-efficient solutions. Agenda: Learn about cutting-edge thermoplastic composites for durable, sustainable and cost-efficient battery housings Explore advanced automation concepts for efficient and scalable production See the latest large-tonnage equipment and technology innovations for e-mobility solutions

That’s a very difficult question because the answer is kind of broad. From my point of view, the mentality of professionalism or expertise is the same across all sectors or occupations. When it comes to plastic molding, I don’t really consider plastic molding manufacturing as much as service providing. When it comes to providing a service, the product must be very reliable, with strong quality control. We have spent many years developing our system and are always trying to be better than perfect. To go beyond being a placeholder and totally exceed expectations. This attitude is the direction of our monozukuri.

For LSR components, the air flow also needs to be changed to reflect the temperatures. Due to the heat generated, the gases mainly escape upward during part removal, which is why the air must be extracted above the mold for LSR injection molding in a cleanroom. By contrast, for thermoplastics, the air extractors are usually located below the mold and the parts in the mold are additionally cooled with fresh air from above in a laminar flow.

Sei Woo Hi-Tech Polymer, Austria, a specialist in microtechnology, combines polyamide (nylon) and LSR on one injection molding machine to form a micro-part. The components are part of an air-inlet valve responsible for the massage function in vehicle seats (Fig. 3). For this purpose, the polyamide (PA) housing base bodies are first injection molded in a 16+16 cavity, rotary-plate mold on an Engel e-victory 140 combi injection molding machine. At the second indexing position, the LSR is injected, while 16 more housing base bodies are produced at the same time. Specially formulated PA and LSR form a chemical bond. However, as the contact area is very small, the finished parts are annealed at 200 C (392 F) after molding for safety reasons in order to permanently bond the thermoplastic and silicone. The parts then pass through camera-based 100% quality control.

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

FIG. 4 The “smart-shut” sliding-ring nonreturn valve by Engel for very low-viscosity melts or LSR and short cycle times is used to help achieve the greatest possible shot-weight consistency, which is essential in micro-parts.

When we interviewed the president of Nissei Plastic Industrial, which is one of the leading companies in injection molding, Mr.Yoda san, he mentioned three main trends affecting the plastic manufacturing sector. The first was, as you’ve mentioned, the increased popularity of sustainable products. The second was surging demand for lighter materials, and the third was cost efficiency. As a company that has been involved with injection molding for the past 50 years can you please tell us how you’re adapting to these trends?

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Molding delicate LSR parts weighing 0.5 mg in 32 cavities requires high precision and repeatability in molding and careful post-mold handling. Here’s a look at the challenges of micro-molding with LSR and what makes it different from thermoplastic micro-molding.

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

That’s a good question, and it's something I've been thinking about a lot recently. What is good for the people who work here? How well can they make a living, have a better quality of life, that’s the key point of what to do next for me. At this moment I haven’t decided anything yet, there are so many choices going forward. A company can choose the future but people as well. I used to think that all people want to be promoted but many don't. Some people just want to stay as they are and that’s their choice. I think it’s very important to provide choices for the people who work here. I want to leave a legacy of sincerity, gratitude, and the idea that Japanese Chuken Kigyo can give people the power to make choices about their future.

Repeatability of the injection movement has an enormous influence on the precision and repeatability of the injection results. But high-quality micro-injection molding is not just a question of the injection unit. Clamp positioning and traverse accuracy also are essential for precise molding of a micro-part. For both LSR and thermoplastics, all-electric, servo-driven machines are therefore a sensible choice in micro-injection molding.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Well that is a long story. It wasn’t easy at all for us to start from scratch. It was a big challenge and took us more than 10 years to do that. I thought, by utilizing this technology to create plastic molds, maybe we can serve society in many ways and create solutions for many people. This is very difficult to digitize because the material is not a digital material. Air conditioning is very critical, we have to maintain a temperature of 23° C plus or minus .05° C, in order to maintain the precision of machining. Plastic molding in general is not as precise compared to what we do. Usually, mold making technologies advance, and plastic mold making follows. We are still struggling to duplicate perfectly, there are so many elements that can create defects.

Another feature of this system is a barrel-coding option that permits replacing the ACH micro-injection unit with a standard screw plasticating unit for LSR or thermoplastic. For processing LSR on the conventional screw with an ACH metering pump, the barrel-coding software disables screw rotation so that it functions just as a plunger, and adjusts the injection pressures and volumes for the barrel diameter.

You’ve mentioned the necessity to gather information. In preparing our report we’ve interviewed many companies and they’ve all agreed on one thing, that research and development plays a major role for Japanese companies. In fact the R&D expenditure for 2019 in Japan stood at 19 trillion yen which shows that Japanese companies are investing massively to be competitive both domestically and globally. We are also seeing a trend where Japanese are shifting overseas to find partners for co-creation and innovation. Can you please tell us about your R&D capabilities? In the future are you looking to find any co-creation or joint venture partners for the gathering or sharing of information overseas?

Thermoplastics do not behave any differently than usual during micro-injection molding: The pellets are fed to a screw and heated barrel. The screw and temperature management ensure that the melt forms homogeneously and can be fed to the cavities shot by shot by means of a sub-runner and valve gate.

Right now I'm researching if there’s anything for agriculture. Biodegradable plastic is a big thing that I’ve been looking at for more than 10 years but it’s not really a good application for us at the moment. In the future plastic will have to be biodegradable, especially for agriculture. Believe it or not we actually started as an agriculture business. My father started with making small planting pots and since then we had to change our direction to focus on chemical parts, and then even smaller parts which led him to create his own molding machines since no one had molds small enough for the parts he wanted to make.

First of all, there is no strategy. It’s quite interesting because my father never had a vision to grow his business too big, he rather wanted to enjoy the work. And so do I. I really enjoy working here. He was very excited about having foreign friends, and real colleagues, who are the people he could trust and do business with. For those local business owners, it was much easier for them to start their own businesses and to get involved with us, so joint ventures happened very naturally. We are still good friends but right now we don’t have too much contact with former joint venture partners.

Micro-injection processes might have worked well under laboratory conditions, but during scale-up and high-volume production, the molders and equipment suppliers face completely new challenges. This applies above all to the dimensional accuracy of the parts. Factors that have virtually no effect on large parts are decisive for the reject rate in the case of delicate micro-parts. Deviations of a few thousandths of a millimeter or a few tenths of a milligram have a major impact on the quality of these tiny parts, and thus on their subsequent reliability in use.

Join KraussMaffei for an insightful webinar designed for industry professionals, engineers and anyone interested in the manufacturing processes of PVC pipes. This session will provide a comprehensive understanding of the technology behind the production of high-quality PVC pipes: from raw material preparation to final product testing. Agenda: Introduction to PVC extrusion: overview of the basic principles of PVC pipe extrusion — including the process of melting and shaping PVC resin into pipe forms Equipment and machinery: detailed explanation of the key equipment involved — such as extruders, dies and cooling systems — and their roles in the extrusion process Process parameters: insight into the critical process parameters like temperature, pressure and cooling rates that influence the quality and consistency of the final PVC pipes Energy efficiency: examination of ways to save material and energy use when extruding PVC pipe products

SIGMA Engineering and Momentive Performance Materials announced a cooperation to optimize material data for silicone elastomers to make LSR molding simulation more reliable.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly