A Quantum Leap for Quality Control in Plastic Injection Molding - medical moldin

Author:gly Date: 2024-09-30

Also, please be aware that the security and privacy policies on these sites may be different than PharmiWeb.com policies, so please read third party privacy and security policies closely.

Unlock competitive advantages with our PDF sample report, detailing market trends, drivers, and challenges: https://market.us/report/plastic-injection-molding-for-medical-device-market/request-sample/

The intelligent control system will optimise the entire moulding process to ensure repeatability, efficiency and lowest energy consumption, this reduces wear and tear on the machine and tooling. It’s as though your most considerate technician has set each machine.

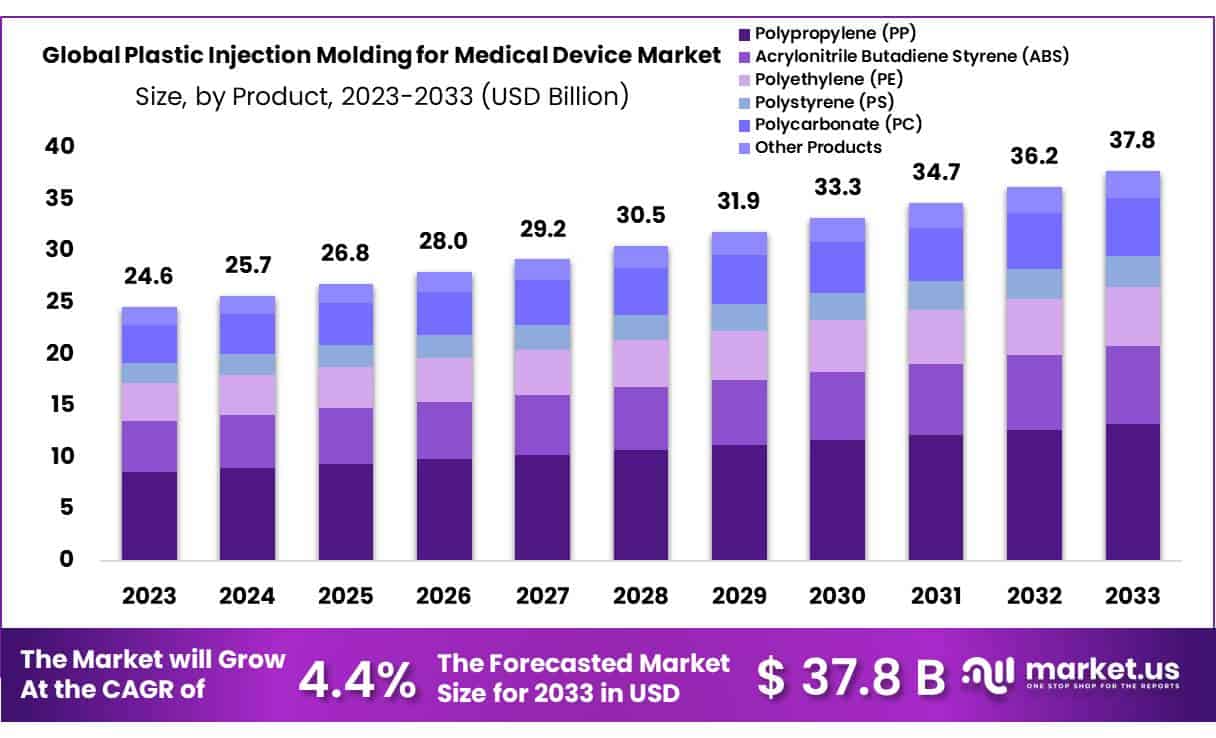

An Increase in Demand and Opportunities for the Global Plastic Injection Molding for Medical Device Market by 2024,” offers a comprehensive analysis of the market by evaluating research and information from multiple sources. This report empowers decision-makers worldwide to positively influence the global economy by providing a detailed overview of the market, including statistics, market size, and competitive conditions.

The Plastic Injection Molding for Medical Device Market report provides a deeper understanding of the industry. This helps in the development and execution of marketing strategies to better target the market. Market research reports can reduce risk, and save time and money. The Plastic Injection Molding for Medical Device industry report can be used to increase the company’s industry knowledge, develop new marketing and advertising strategies, and identify the right demographics. The Plastic Injection Molding for Medical Device Market Report has the most comprehensive research and the required expertise to ensure and receive the right information. This applies regardless of whether businesses want to analyze existing or emerging markets or find new product trends.

Well, as you know, we have been very vocal about the need for the UK Plastics Sector to invest in modern technology so that it can improve competitiveness and produce a rapid return on investment. According to the PMMDA, the UK has the oldest fleet of machinery in Europe, outside of Romania, and at the current rate will take more than 20 years to upgrade. In the meantime, European moulding companies are racing ahead, with governments offering financial assistance to their manufacturers to help reduce their carbon footprint and improve efficiencies. Generation 5 offers energy savings of between 20% and 40% on our previously already impressive figures. This is showing circa 80% energy savings vs. fixed or variable pump machines, which still make up the bulk of the UK market.

Unlock competitive advantages with our PDF sample report, detailing market trends, drivers, and challenges: https://market.us/report/plastic-injection-molding-for-medical-device-market/request-sample/

The new Generation 5 range of Haitian moulding machines will be hitting UK shores in the coming weeks. Veronica Edmunds, head of the UK sales team, shares what we can expect from one of the world’s largest manufacturer of moulding machines.

PharmiWeb.com is Europe's leading industry-sponsored portal for the Pharmaceutical sector, providing the latest jobs, news, features and events listings.The information provided on PharmiWeb.com is designed to support, not replace, the relationship that exists between a patient/site visitor and his/her physician. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

The Plastic Injection Molding for Medical Device market boasts a strong global foundation. The market research report conducts a thorough analysis, forecasting future trends, growth factors, consumption and production volumes, as well as CAGR numbers. Moreover, it offers recommendations, profit margins, and pricing data sourced directly from the market, aiding market participants and individuals in predicting future profitability and making informed business decisions.

• -To analyze and study micro-markets in terms of their contributions to the Plastic Injection Molding for Medical Device market, their prospects, and individual growth trends.

To understand how our report can make a difference to your business strategy, Inquire about a brochure at https://market.us/report/plastic-injection-molding-for-medical-device-market/#inquiry

The Global Plastic Injection Molding for Medical Device Market Report Also Encompasses The Regional Analysis To Offer The Complete Regional Development Status. Additionally, The Report Also Provides Necessary Recommendations And Suggestions For The Plastic Injection Molding for Medical Device Market Players So As To Attain A Competitive Edge In Various Regions. It Also Provides Market Size And Forecast Estimates From the Year 2024 To 2033 About Five Major Regions,

The report provides insights into the future needs and potential opportunities of the Plastic Injection Molding for Medical Device market, highlighting key market players and their roles. Utilizing key market dynamics and growth variables, the report calculates market value and growth rates. Drawing from current industry news, market trends, and growth projections, it also presents a detailed analysis of market and competitor scenarios, including a SWOT analysis of prominent competitors.

Whilst the centre is certainly an impressive facility from which to showcase our technology, it is also available to support customers in their machinery selection processes. We have already run multiple tool trials, energy comparisons and training sessions. This investment in our UK infrastructure extends to the provision of a full-quality office to enable our customers' teams to fully investigate their own tools' performance in our machines. Our engineering team work alongside our customers to ensure that the best possible outcomes can be achieved. We have also been able to assist customers with some small production runs when needed.

The “Generation 5” range continues Haitian’s philosophy of sharing the advantages that their economies of scale produce, with our customers. This time the step change is higher than previously seen, and that is because technological improvements are happening so quickly. We have over 700 people working in R&D, in a constant quest to innovate and improve. There has been a massive increase in investment by Haitian to improve their manufacturing excellence and infrastructure, including a new site in Serbia to manufacture up to 3000 machines a year for the European market.

If you have any questions or concerns about the products and services offered on linked third party websites, please contact the third party directly.

Savings of these magnitudes offer moulders the opportunity to pay off their brand-new Haitian Generation 5 machine, with the savings they make on energy, in months rather than years.

PharmiWeb.com offers links to other third party websites that may be of interest to our website visitors. The links provided in our website are provided solely for your convenience and may assist you in locating other useful information on the Internet. When you click on these links you will leave the PharmiWeb.com website and will be redirected to another site. These sites are not under the control of PharmiWeb.com.

PharmiWeb.com is not responsible for the content of linked third party websites. We are not an agent for these third parties nor do we endorse or guarantee their products. We make no representation or warranty regarding the accuracy of the information contained in the linked sites. We suggest that you always verify the information obtained from linked websites before acting upon this information.

The aim for us, in a commercial sense, is to provide the best machine price-performance ratio, coupled with such a high level of customer service that our customers do not consider using another supplier. It’s proved to be a successful formula so far and we are sure that the introduction of Generation 5 will X-Tend this advantage.

Disclaimer: You are now leaving PharmiWeb.com website and are going to a website that is not operated by us. We are not responsible for the content or availability of linked sites.

• -To carefully analyze and forecast the size of the Plastic Injection Molding for Medical Device market by value and volume.

To support the launch of the new Generation 5 machines, Haitian UK has recently opened a new Technical Centre in Buckinghamshire. Onsite, we have a selection of machines from our Haitian and Zhafir ranges plus our Hilectro automation, ranging from 90 to 550 tonnes. All are available for sale and quick delivery if required.

While energy savings and a quick return on investment are often enough of an incentive to add to our rapidly expanding customer base, we believe the new HT-X tend software will further set us apart from our European and Asian competitors.

• -To showcase the development of the Plastic Injection Molding for Medical Device industry in different parts of the world.

-To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Plastic Injection Molding for Medical Device market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

The HT X-tend software is available on all Generation 5 and is included as a standard option in the purchase price. Charging customers extra for features that are included on their machines is a policy that has backfired on those suppliers who have tried it. Customers remember when car companies tried to charge to use heated seats that were already fitted in their vehicles, and the same reaction is commonplace in our sector when manufacturers will “switch on features for a price”. Our system is free of charge and can be turned on and off, by our customers, whenever they require it. This software has been tested on over 1000 machines pre-launch and the improvements achieved when processing recycled material are of particular benefit.

Premier Moulding Machinery has been the Haitian distributor in the UK for almost 20 years, so obviously we have seen huge changes in technology over that time. I guess it shouldn’t come as a surprise to any of us that this fifth generation from the market-leading manufacturer is so impactful. Haitian have always positioned themselves as a high-quality brand, for whom the customer’s experience is paramount. Unlike some suppliers, we are not in a race to deliver the cheapest functioning machine or, conversely, to use customers as revenue streams post-purchase.

PharmiWeb.com is Europe's leading industry-sponsored portal for the Pharmaceutical sector, providing the latest jobs, news, features and events listings.The information provided on PharmiWeb.com is designed to support, not replace, the relationship that exists between a patient/site visitor and his/her physician.

We aim to provide the highest level of customer support alongside the best machinery available at a price which is affordable for all. In particular, I would also like to give credit to our own engineering team whom our customers continually praise for the excellent levels of service they provide. Whilst it may be the sales team who sells the first machine to a new customer, it is the engineers who sell the rest. Time and time again, we hear how important it is to be supported by a team who have the customers' best interests at the forefront of what we do. Haitian UK have a policy of not using our engineering support as a revenue stream which enables a strong working relationship with our customer base.

Features which were previously available as additional options are now included as standard specifications, including new energy-saving technology, both hardware and software. It’s fair to say that these options would have cost thousands of Euros previously, but our economies of scale make it more cost-effective to upgrade the whole range. So, for example, Haitian Generation 5 Servo hydraulic machines will now offer Electric Screw Motors as standard, at no extra cost. Thus, enabling a more precise and reliable process with reduced energy consumption, not to mention that they are a lot quieter too.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly