A Quantum Leap for Quality Control in Plastic Injection Molding - medical moldin

Author:gly Date: 2024-09-30

The new laser polishing machine developed at the ILT has the potential to save considerable time and money in these areas. "The machine polishes surfaces up to ten times faster than a hand polisher and is an excellent option for serial production and for polishing small batches," explained Willenborg.

Now, there may be an easier, faster way to polish mold components. Two companies in Germany have joined forces - Maschinenfabrik Arnold and S&F Sytemtechnik - in collaboration with researchers at the Fraunhofer Institute for Laser Technology (ILT) and developed a machine tool which can polish both simple and complex surfaces using laser beams. This new technology will be presented in December at this year's EuroMold trade fair in Frankfurt (Hall 11, Booth C66).

Willenborg noted, "When a highly skilled hand polisher has a lot of time and a high quality steel, he can achieve a roughness below RA 0.01 microns. We do not expect to get to this level with laser polishing, but as stated before, we address the applications where a medium surface finish is enough."

EDM finishes are extremely good, and many times that is the finish required. If something better is required, Tech Mold will take a component with an EDM finish to its polishing department where it will be put through the process of hand polishing, Kushmaul explained. "EDM finishes are getting better and we can achieve finer finishes with EDMing," he added, "which meets the needs of many plastic components. With good mold polishers getting harder and harder to find, and the need for good, consistent detail in the finished component, it will be interesting to see where the laser polishing system can take us."

Mold polishing is perhaps one of the most critical phases of the mold build (and in mold repairs), and for decades it's been primarily a manual operation. Every mold company has one or two employees in a corner sitting under a bright light, bent over their work piece, painstakingly polishing with grinding stones, meticulously working with finer and finer abrasives until, micron by micron, the surface is perfect. This is time-consuming work and according to Karl Szanto, operations manager at injection mold manufacturer Tech Mold Inc. can represent as much as 8-12% of the total number of man-hours in a mold build.

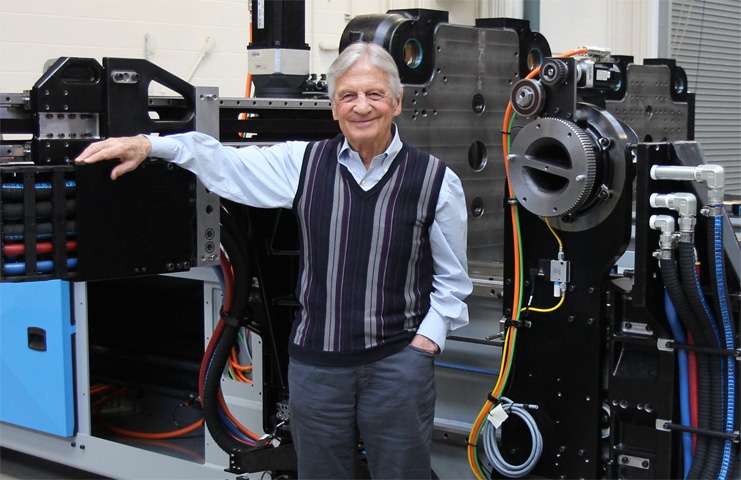

Schad eventually left behind the company he built after selling his majority stake in 2007 to Canadian private-equity investment firm Onex in a deal worth C$960 million overall. "It didn't work out to stay," he says simply.But Schad found he couldn't leave behind what he'd been doing since founding Husky in 1953 as a small machine shop. Originally intending to build air-boats after Husky, his attention soon returned to the plastics processing machinery he knows so well, and the Athena concept was born in 2008. "When I started, I set some very precise goals," he says of Athena. "I would either accomplish them or give up.""The main idea is to build a simple, cost-effective platform with energy consumption similar to all-electric injection molding machines. It can now be automated with the features needed all built into the machine. It's simple to install, and can be customized very quickly and cost effectively," Schad says.The Athena line utilizes servomotors in a hybrid platform to achieve repeatability and accuracy "as good as or better" than all-electrics while maintaining low energy consumption in part due to the active power supply that regenerates braking energy. The machines have a small footprint with large daylight and are quiet, operating at under 70 dB.The Athena machines will range from 150 to 500 tonnes, with screw diameters of 30-120 mm. A clean-slate, and cleanroom-ready design philosophy are at the heart of the Athena approach. The machines are built on a one-piece base and feature distributed controls interconnected by a PowerLink bus. All machines feature 150 mm of floor clearance for easy cleaning. All service connections (water, air, vacuum, electrical) are located at the injection end of the machine. Services are pre-routed through the machine base. Also standard are two-platen electric clamps with non-lubricated tiebars and a closed loop, leak-free oil return system for hydraulic components.A wide range of options include a fully integrated high-speed, side-entry robot, stack-mold carrier, integrated dual injection, and integrated hot runner and robot control, meaning the machines can quickly be adapted for in-mold assembly and rotary cube automation. Athena is partnering with SIPA in its PET solutions ("Athena for SIPA"), offering PET preform systems up to 96 cavities. PET systems are sold and serviced by SIPA under the XFORM brand. Athena will be on SIPA's stand at the upcoming DrinkTec and K shows. "The program is very beneficial to a lot of people," says Schad.Athena currently occupies a 40,000-sq-ft facility that houses R&D, labs and assembly, with plans for a 150,000-sq-ft building sometime in 2015. The company currently has 58 employees."Now we have a nucleus that we can introduce," says Schad, "one platform for many different applications, including medical, closures, and preforms all on one platform. There are many excellent machines in the market, which are overkill. We've scaled it down to basics and added pre-engineered options to roll it out to different markets."When asked what he envisions for the new company, Schad says: "Let's assume we win. I'd like to see a private company that my family is holding together with the employees." As always, Robert Schad knows exactly what he wants.

"I don't like to build what people want; I like to build what they need," Robert Schad told PlasticsToday upon the public debut of his new hybrid molding machine company, Athena Automation (Toronto, ON), at an open house coinciding with the recent Plast-Ex 2013 show (May 14-16; Toronto, ON).

Depending on the material, the project team's initial trials can produce surfaces with an average roughness (Ra) of between 0.1 and 0.4 microns. "Hand polishing can still get better results than that," Willenborg admits, "but the point is that in many applications - for example molds for glass-making, forming and forging tools - a medium-quality surface is all that is needed."

Willenborg added, "We do not want to be better than the manual polisher, but we want to be faster and cheaper for the medium quality range, which will ultimately reduce the cost to both the mold maker and the end user."

The calculated beam path data is then supplied to a special post-processing software program developed at the ILT. This program configures more advanced aspects of the process, such as adapting the laser to the specific angle of incidence and component edges in each particular case.

Until she retired in September 2021, Clare Goldsberry reported on the plastics industry for more than 30 years. In addition to the 10,000+ articles she has written, by her own estimation, she is the author of several books, including The Business of Injection Molding: How to succeed as a custom molder and Purchasing Injection Molds: A buyers guide. Goldsberry is a member of the Plastics Pioneers Association. She reflected on her long career in "Time to Say Good-Bye."

"Conventional methods remove material from the surface to even it out," says Edgar Willenborg, section head at the ILT in Aachen, also Germany. "Our method is different: it uses laser to melt a thin surface layer roughly 20 - 100 microns deep. Surface tension - a property that applies to all liquids - ensures that the layer of liquid metal solidifies evenly."

However, Willenborg added that he and his team "expect improvements with ongoing research" in the next few years. "But, we do not expect to dramatically reduce the achievable roughness in a short time," he said. "In the lab, we have achieved a roughness of Ra = 0.05 microns on a turned surface with an initial surface roughness before polishing of Ra = 5.00 microns. But at the moment we can achieve this only with precisely controlled conditions."

Mold polishing is perhaps one of the most critical phases of the mold build (and in mold repairs), and for decades it's been primarily a manual operation. Every mold company has one or two employees in a corner sitting under a bright light, bent over their work piece, painstakingly polishing with grinding stones, meticulously working with finer and finer abrasives until, micron by micron, the surface is perfect.

This new technology also offers benefits in terms of machine development. "The fact that we are working with a completely new operating principle makes it much easier to construct the machines we need," Willenborg said. "Unlike conventional polishing techniques, laser polishing does not primarily rely on the rigidity of the machine to achieve high component quality, but rather on the physics of surface tension."

"I don't like to build what people want; I like to build what they need," Robert Schad told PlasticsToday upon the public debut of his new hybrid molding machine company, Athena Automation (Toronto, ON), at an open house coinciding with the recent Plast-Ex 2013 show (May 14-16; Toronto, ON).Most anyone in the plastics processing industry will recognize the name of the iconoclastic founder of Husky Injection Molding Systems, which the German-born Schad built into one of plastics' most dominant injection molding machine makers, especially in the PET preform and closures market. If Schad sounds a bit like Apple's Steve Jobs he has good reason. The visionary, no-nonsense leader recognized the virtues of vertical integration early on, meaning Husky not only made injection molding machines, but also molds, hot runners, robots, and auxiliaries.

Cores are expertly polished at Tech Mold. But soon maybe lasers can do much of a polisher's work, as shown in the photo below (laser treated part on the right).

A year ago, Willenborg and the ILT approached Tech Mold about this technology. Tech Mold gave the ILT a sample mold component on which to work. "The sample looks good," commented Bill Kushmaul, as he showed PlasticsToday the part which had a hand-polished area next to an area that was laser polished. "The technology is there, but it needs to be refined. We believe they'll achieve what they're trying to do."

The system consists of a 5-axis gantry plus an additional 3-axis laser scanner, a design that allows the work piece to be accessed from all sides. Strategically placed mirrors deflect the laser beam to allow feed rates (the speed at which the laser beam moves along the work piece within a specified time frame) in excess of one meter a second, even on small surfaces.

The big question is whether or not you can get a perfectly flat surface. It can be made shiny but can it be made flat? "If they achieve this it will be a real breakthrough in the mold making industry," said Kushmaul. "Currently, polishing represents a significant number of man-hours at the end of the mold component manufacturing process."

An end-to-end CAM NC data chain has also been developed which draws on a 3D CAD model of the component to be polished. The beam path data is calculated on the basis of this model. "For this step, we use conventional computer-aided manufacturing (CAM) programs such as those used in milling processes," said Willenborg. "The advantage is that companies are typically running those kinds of programs so the employees know how to use them."

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly