What Do Automotive Companies Use Injection Molding For? - automotive injection m

Author:gly Date: 2024-10-15

When making prototypes or small-lot mass production of plastic parts, it is necessary to create molds if you want to make prototypes using the same materials and molding conditions as the actual production. However, the cost of molds is very expensive. Our prototype molds address such problems.

We have been involved in small-lot injection molding since early on, and we can use our experience to respond quickly to the needs of R&D departments. We manufacture prototype molds using aluminum material (A7075S) with excellent machinability.

For questions regarding our quote form, data transfers or our FTP site for large files, please contact our data coordinator midwestmold@midwestmold.com.

With 2 shot molding, parts can include a clear window, integrated gaskets, movable segments, water shields, or sound or vibration reduction.

Daytech Co,Ltd. is located in Tokyo, Japan, developing "prototype plastic injection molds" and supplying plastic parts for electronics, medical industries and household-appliance industries, especialy for R&D divisions. One of our best practice of plastic injection molds is creating molds by Alminum such as Al7075S. We cut alminum plastic molds directory. By doing so, the molds are precise and small-sized, and it benefitial for companies which aim to develop small lot of precision plastic parts. Prototype molds are not plastic injection molds that can be used only for prototyping. With our unique technology, we can use prototype molds for injection molding from prototypes to small-lot mass production with the same quality as mass production. Small-lot mass production is possible for 100 to 5,000 units, depending on the shape, and we have experience with up to 10,000 units.

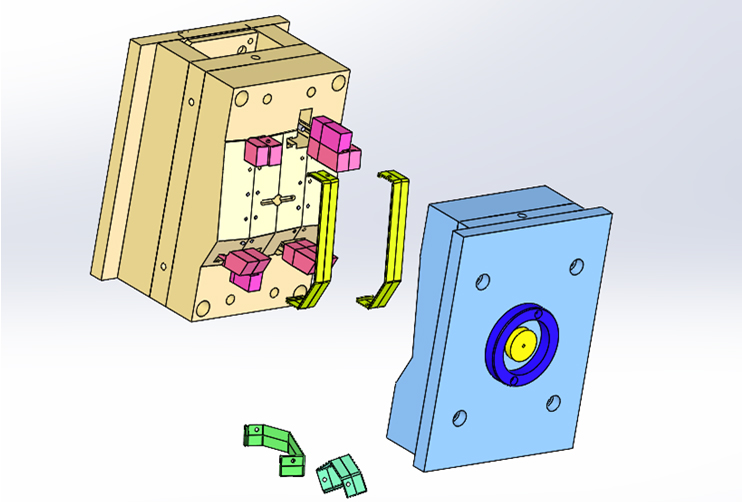

The mold base is our original "cassette type", and the slide mechanism is supported by the placement piece. Aluminum (7075S) is used for the cavity, core, and base. As a result;

2 shot injection molding reduces the number of machines and molds required to mold two materials together into one part, and it minimizes part handling, all of which can add up to lower costs. In addition to financial benefits, 2 shot molding can provide:

Midwest Mold specializes in the design and build of 2 shot plastic injection molds and has successfully manufactured pre-production and production tooling for structural, water management, crash impact and noise reduction applications.

2 shot plastic injection molding enables the use of dissimilar resins to be used in a multi-part assembly. In some instances, a 2 shot mold application may include different colors and also soft and hard materials assembled together in in a single part. Some of the benefits of 2 shot plastic injection molding include elimination of post-molding assembly, fewer injection molding machines to make a single part and reduced part handling by operators by utilizing a single molding operation.

We can also design plastic parts. If you provide us with specifications and drawings, we can provide a one-stop service from material arrangement to design, prototyping, mold making, and injection molding.

Midwest Mold offers a cost-effective solution to challenges caused by parts that require the use of two different plastics. 2 Shot injection molding is a process that molds one part using two different plastic resins. This enabling technology allows you to use two colors of plastics or to integrate both hard and soft plastics into one part without any post-molding assembly.

Your Name: Your Email: Resin: Estimated Life of Program: Estimated Annual Volume: Estimated Order Quantities (if Low Volume Molding Project): Target Price (Tooling/Piece Part): Message Attach a File ❌ ❌

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly