Using Plastic Molding for Plastic Pallets - Prototool - plastic pallet mould

Author:gly Date: 2024-10-15

cavities and the surface finish. When you are mass producing then this method is ideal because the cost per part will be very low.

ABS material drying temperature : ABS material is hygroscopic and must be dried, drying conditions 80-90°C, 3hrs or more,

When using this method your outcome product will continuously have the same shape along the length of it. These can be things like straws or PVC pipes. These types of parts can be made at very high volumes because it can just keep producing the same shape without end.In comparison, this type of moulding is low cost because the equipment is fairly simple and can have high productivity. The downside to this method is that you are very boxed in when it comes to the variety of parts you can make.

ABS Material Type: Different ABS material, the MFI is different, which will affect the size and position of the gate runner.

The viscosity of ABS molten parts is higher than that of polystyrene or modified polystyrene, so a higher injection pressure is used during injection. Of course, not all ABS parts need to be injected at high pressure, but small, simple and thick parts can be injected at a lower pressure. During the injection process, the pressure in the cavity at the moment of gate closure often determines the surface quality of the product and the degree of silver wire defects. If the pressure is too low, the plastic shrinks and has a greater chance of disengaging from the cavity surface, resulting in a hazy surface. Pressure is too large, the plastic cavity surface friction is strong, easy to cause sticky mold.

Standard plastic injection molding machine can be used (screw L/D ratio 20:1, compression ratio more than 2, injection pressure more than 150MPa). If the use of color masterbatch or product appearance requirements are high, the use of a smaller diameter screw. The clamping force is determined according to 4700~6200t/m2, depending on the plastic grade and product requirements.

Mould Cavity: Different number of cavities will affect the choice of gate position, usually the number of cavities will be selected according to the size of the injection molding machine.

Shrinkage: The shrinkage rate of different sizes of ABS products will be a little different, the common range is 0.4-07%, 0.5% is recommended.

These 5 types are extrusion moulding, compression moulding, blow moulding, injection moulding and rotational moulding. We will look at the details pertaining to each of these methods so that you can decide which one will be the most effective for you to use.

This is a common method to produce a high volume of plastic parts like car parts or even parts for surgical applications. Products can also be made with increased flexibility to suit the needs of designers or engineers.

4.deformation of the ejector plate or injection molding machine top stick length, resulting in unbalanced ejections and pull white.

The moulds that are used in rotational moulding are highly intricate to make products customizable and changeable. This can include things like special inserts and curves as well as logos and slots. These can be placed into the mould to change the final product.

This method involves the raw liquid plastic being poured into a heated mould and then being compressed together to form the desired shape. The high temperature of the entire process ensures good strength in the final product. The process is finished off by cooling the liquid plastic so that it keeps its form before being trimmed and removed from the mould.

ABS material with medium injection speed is better. When the injection molding speed is too fast, the plastic is easy to scorch or decompose and precipitate vaporized products, so that defects such as fusion seam, poor gloss and redness of plastic near the gate appear on the parts. However, in the production of thin-walled and complex parts, it is still necessary to ensure a high enough injection molding speed, otherwise it is difficult to fill.

With the detailed mold flow analysis results, the mold making and injection molding will not be much different, saving the production time and reducing the cost of production.

The molding temperature of ABS is relatively high, and the mold temperature is also relatively high. When producing parts with large projection area, the fixed mold temperature should be 70~80℃ and the moving mold temperature should be 50~60℃. In order to shorten the production cycle and maintain the relative stability of mold temperature, cold water bath, hot water bath or other mechanical shaping method can be used to compensate for the time of cold fixing in the cavity after the parts are taken out.

The tooling costs with rotational moulding are lower than other methods like injection and blow moulding. This makes for lower start-up costs and more effective production costs even at low volume production.

The most effective use for this method is when you want to make plastic replacement parts for broken metal parts. The reason for this is because the high-temperature method makes for a very strong and durable end product. Even though it is plastic, it is a strong and low-cost replacement for the metal parts.

This is a fast and economical friendly option with the mould prices ranging somewhere in between injection moulding and rotational moulding.

Tonnage of Machine: When injecting ABS plastic, the injection volume per shot is only 75% of the standard injection volume.

ACIS®, Autodesk Inventor®, CATIA® V5,Creo™ Parametric, IGES, Parasolid®, Pro/ENGINEER®,Siemens PLM Software’s NX™, SolidEdge®, SolidWorks®, STEP

Injection Moulding is fairly similar to extrusion moulding. The difference here is that with injection moulding the melted plastic is injected directly into a custom mould. The injection is under high pressure so that the mould is filled and a solid part is made. As with the other methods, after the mould is filled, the plastic is cooled as to keep its new shape and then the mould is opened.

When injecting ABS plastic into general injection molding machine, each injection volume is only 75% of the standard injection volume. In order to improve the quality and dimensional stability of the parts, surface gloss and uniformity of color, it is appropriate to require an injection volume of 50% of the standard injection volume.

Plastic moulding is the process of pouring liquid plastic into a certain container or mould so that it hardens in that customized shape. These plastic moulds can then be used for a wide range of purposed. There are 5 types of plastic moulding that is considered to be the most effective and most popular.

This method is very material efficient and very little goes to waste making it more economical and environmentally friendly.

According to the complexity of the structure of the ABS product mold to do different processing arrangements, if the mold structure is simple, as long as the CNC milling, EDM processing can be completed mold, if the mold structure is more complex, will carry out a series of processing technology. For example, CNC, EDM, Deep hole Drill, Lathe, Grinding Machine, Wire-Electrode Cutting, CMM, Polish and Injection.

ABS is composed of acrylonitrile, butadiene and styrene. Acrylonitrile mainly provides chemical resistance and thermal stability; butadiene provides toughness and impact strength; and styrene provides hardness and processability for ABS. The combination of the three materials forms a comprehensive plastic.

6.The ejector structure is unreasonable, the ejector pin is not under the maximum clamping force, and the ejector is deformed.

ABS plastic is hygroscopic and sensitive to moisture, sufficient drying and preheating before processing, not only to eliminate water vapor caused by the surface of the product smoky bubble, silver, but also help plasticization, reduce the surface color of the parts and cloud pattern. ABS raw materials to control the moisture below 0.13%. The drying conditions before injection are: 2~3h at 75~80℃ during the dry season or winter, 4~8h at 80~90℃ during the rainy days in summer, and longer drying time of 8~16h if the parts have to achieve a particularly good gloss or the parts themselves are complicated. It is advisable to convert the hopper of the machine into a hot air hopper dryer so that the dried ABS does not reabsorb moisture in the hopper, but this type of hopper should be monitored for humidity to prevent overheating of the material in case of occasional interruptions in production. The proportion of recycled material should not exceed 30%, and recycled material should not be used for plating grade ABS.

It is not easy to do a good job of ABS injection molding products, need years of experience in mold and injection molding, in product design and mold design need to do a lot of analysis, especially mold flow analysis must be done, only the design of the product in line with the mold production requirements, mold design in line with the requirements of injection molding production, so that the products made to achieve the expected results, even if the product injection are normal, but also need to do a good job in time mold Maintenance, such as checking whether the waterway is blocked, whether there is leakage of ABS material, whether the mold is touched in the production process, etc. This series of problems are well controlled to ensure that the production of ABS products is smooth, so it is very important to find a qualified ABS injection molding manufacturer.

The most common use for this method is for big and hollow parts. These parts include car parts, bins, kayaks, road cones, pet houses and storage tanks.

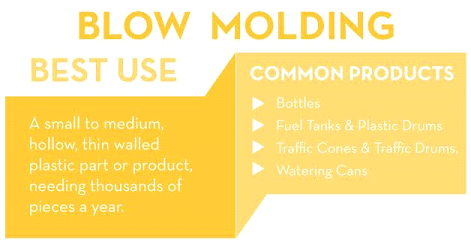

Blow Moulding is mostly responsible for producing products like plastic bottles, drums, cases and even fuel tanks. If your required number of parts is around the hundreds of thousands then this method is perfect for you (like a soda company).

The other forms of plastic moulding also use extrusion so get the raw liquid into the moulds, the difference here is that other methods use the moulds to make the desired shape and here the extrusion itself is making the shape with the use of the die’s shape.

1.The holding pressure is too large, the internal stress is large, and the deformation is large within 24h after leaving the mold.

Please feel free to get in touch with any of us about anything. We are more than happy to discuss with you, your next project.

Draft Angle: ≥1.5°, the draft angle not only affects the mold release, but also the appearance and assembly of the product. The side wall of plastic parts with skin pattern, sandblasting and other appearance treatment should take a draft angle of 2°~5° according to the specific situation.

The relationship between temperature and melt viscosity of ABS plastic is different from that of other amorphous plastics. Once it reaches the plasticization temperature (the temperature range suitable for processing, such as 220-250℃), if we continue to raise the temperature blindly, it will lead to the thermal degradation of ABS, which is not very heat resistant, and increase the melt viscosity, make injection more difficult, and decrease the mechanical properties of the parts. Therefore, although the injection temperature of ABS must be higher than that of polystyrene and other plastics, it cannot have a more relaxed temperature range like the latter. In some injection molding machines with poor temperature control, when a certain number of ABS parts are produced, more or less yellow or brown coke particles are found embedded in the parts, and it is difficult to remove them by adding new material to the empty injection. The reason for this is that ABS plastics contain butadiene, which causes degradation and carbonization when a plastic particle adheres firmly to some hard-to-wash surface in the screw tank at high temperatures and is subjected to prolonged high temperatures. Since high temperature operation can be a problem for ABS, it is necessary to limit the furnace temperature in each section of the barrel. Of course, the applicable furnace temperature varies for different types and compositions of ABS. For example, for plunger type machines, the furnace temperature is maintained at 180-230°C; for screw machines, the furnace temperature is maintained at 160-220°C. In particular, it is worth mentioning that ABS is sensitive to changes in various process factors due to its high processing temperature. Therefore, the temperature control of the front end of the barrel and the nozzle part is very important. It has been proven that any small change in these two parts will be reflected in the part. The greater the temperature variation, the greater the defects such as fusion seam, poor gloss, flying edge, sticky mold, and color change.

2. the syringe needle is too high, resulting in local glue bit is too thin, the periphery of the first fill, to the center of the intersection to produce fusion line.

With extrusion moulding, hot melted plastic is pressed through a shaped hole to create a lengthy shaped plastic part. This customizable shape that the liquid plastic gets pressed through is called a die. This die is custom made for the particular outcome that is desired. It is almost like pressing dough through a press to make shaped cookies.

When it comes to the pricing the moulds can be very expensive because they need to be steel or aluminium for higher strength and durability. Luckily, as with most methods, the cost per unit drops drastically depending on your production volume.

The machine heats up the raw plastic until it becomes liquid and then injects air into it like a balloon. The plastic is blown into a shaped mould and as it gets bigger it presses against the mould walls and it starts to take its shape. After the liquid balloon fills the mould it is cooled to keep its shape. The process is very fast and can produce up to 1400 pieces in a 12-hour work day.

Also sometimes called rotomoulding, this method involves the resin or liquid being placed inside the mould and then being rotated at high speeds. The liquid then evenly covers the entire surface of the mould to create a hollowed part with all the walls evenly thick. After the mould is cooled and the liquid plastic has taken its new form it is then taken out of the mould.

With blow moulding, the custom plastic parts come out hollow and thin-walled. This method is ideal for when the plastic part has to have uniform wall thickness. This is very similar to the process of glass blowing.

Injected Molded ABS Parts have become more and more common in life. Most plastic housings are made of ABS, such as household appliances, electronic products, game consoles, water purifiers, as well as industrial exterior parts, automotive interior parts, high-end garden planters, supermarket shelves, etc.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly