USA Manufacturer | Custom Injection Molding & CNC ... - plastic injection moldin

Author:gly Date: 2024-10-15

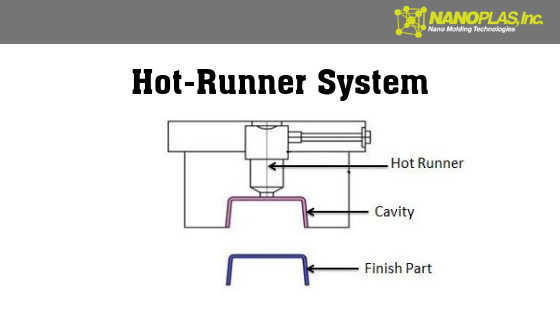

There are two types of hot-runner mold systems, both of which use two plates heated by a manifold system. Externally heated molds allow you to use more heat-sensitive polymers while internally heated molds generate better flow control. Depending on your materials and applications, you may prefer (or need) one type over the other.

Why should you choose a hot-runner mold system over a cold-runner mold system (or vice versa)? Each type of molding system has unique features that help determine exactly which one is best for you.

A short shot is the incomplete filling of a mold cavity which results in the production of an incomplete part. If a part short shots, the plastic does not fill the cavity. The flow freezes off before the flow paths have completely filled. To ensure the finished part is of good quality, the part must also be adequately packed with plastic. Therefore the question to ask is not only, “Will the part fill?” but also, “Can a good quality part be made?” Causes

In a cold-runner mold system, the runner has to be larger than the part. Otherwise, you run the risk of underfilling the mold. One big advantage over a hot-runner system is the ability to use more types of polymers without concern for heat sensitivity.

According to the size of the machine, how much per injection, so as to determine the product ranking mode and the number of holes. The more the number of moulds produced, the lower the cost of injection moulding. Because the cost of injection moulding is calculated according to injection order.

Depending on exactly what you’re doing with your molds—materials, applications, size, volume, etc.—you may have a clear answer as to the best mold system or it may be more complicated. For instance, if you’re only working with heat-sensitive polymers, a cold-runner mold system is probably your best choice. If you’re producing large volumes and need faster cycle times, you’re probably looking for a hot-runner mold system.

What is the injection mold? Injection mold is a tool for producing plastic products; it is also a tool for imparting complete structure and precise size of plastic products. Injection molding is a processing method used in mass production of complex parts of certain shapes, specifically refers to plastics that melt by heat from injection molding machines. High pressure is injected into the cavity, and after cooling and solidification, a molded article is obtained. Mold application: Mold is the basic process equipment for […]

Three-plate systems allow the part to be ejected from the runner without an ejection system, but are a little more complicated than a two-plate system, which does require an ejection system to remove the part and the runner from the mold. Two-plate systems can handle most molds, however a three-plate system is friendlier when it comes to complex designs.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

With the continuous development of automotive electronics, higher requirements for product modeling, JasonMould here shares the five steps in the injection molding process. 1. The mold structure design A set of high-quality molds requires not only good processing equipment and skilled mold making workers. Another very important factor is good mold design, especially for complex molds. The mold design accounts for more than 80% of the mold quality. An excellent mold design is: under the premise of meeting the requirements of customers, the […]

Select the appropriate molding equipment, determine the reasonable process conditions, if the injection molding machine is too small to meet the requirements, too […]

Overall, hot-runner molds produce parts with more consistent quality and do so with faster cycle times, but it’s not as easy to change colors nor can hot runners accommodate some heat-sensitive polymers.

According to the product appearance requirements, determine the parting surface. The position of parting surface should be beneficial to die processing, exhaust, demoulding, etc. The more products, the greater […]

Automotive plastic parts are used more and more widely. Automotive plastic parts are not only cheap, but also environmentally friendly, beautiful, convenient and durable. Nowadays more and more automobile metal parts are replaced by plastic parts. In order to ensure the normal operation of various parts, the maintenance and maintenance of automobile plastic parts are also very important. Maintenance methods of automotive plastic parts:

Cold runners are less expensive than hot runners and are easily maintained as well, but they can create waste unless you can recycle or melt down the extra material.

Compared with other moulds, the structure of injection moulds is more complex and precise , the operation and maintenance of the product requirements are higher, so in the entire production process, the use of positive solutions and careful maintenance, maintenance to maintain the normal production of enterprises, improve the efficiency of enterprises, has a very important significance.

Excellent weather resistance, guaranteeing long-term use without color, aging cracks (including heat and oxygen aging and light aging); Good chemical resistance, to resist the erosion of oil and daily chemicals; Easy moulding, the injection grade material should have enough fluidity to ensure the moulding of complex components and improve production efficiency. Economy requires material with high performance-price ratio. Material requirements for exterior accessories Weather resistance: Weather resistant materials such as AES, ASA (AAS), PC/PBT (PET) should be selected for parts that are not coated […]

Djmolding is a professional china plastic injection molding or moulding company with mould and dies development and manufacturing

The main determinant is the total number of products that customers need to produce. It takes about the same time to produce a product. Multiply the time to produce a product by the total amount of production the customer needs to produce to figure out how long it takes. Material and machine preparation time should also be taken into account before formal production. The preparation time of the machine is very short, because the equipment of the injection moulding factory […]

Called a cold-runner mold system because the runners are the same temperature as the molds, there are two types of cold-runner systems: a three-plate system and a two-plate system.

Also known as “bumper”, but in fact it is only the auxiliary shell outside the bumper, not the body of the bumper. Bumper housing plays the role of cushioning and energy absorption, the working environment is relatively complex, and the volume is larger, so it is generally made of polypropylene (PP), because of its lighter weight and better corrosion resistance.

However, those aren’t definite answers and shouldn’t be taken as such. You need to consider every facet of what you’re doing to determine the best system for you. Feel free to contact us if you’d like to talk about which type of mold system is your best option.

Nanoplas brings innovative mold maintenance products to the plastic injection mold industry. Browse our selection of mold coatings, greases, cleaners & more!

Apart from wood and leather, the dashboards of automobiles are basically plastic, but there are differences between hard and […]

Weld Lines The flowing defects on product surface or the linear defects that are caused when melt fronts meet each other after splitting. Weld lines refer to the lines that occur on a plastic product surface when the cold slug melts. In areas of mold cavity where the molten plastic meets inserts or holes, areas with inconsistent flow speed/flow interruptions, where multiple flows meet or when jetting happens during mold filling, linear weld marks tend to occur due to imperfect bonding. […]

Hot runners are more expensive than cold runners (in initial investment and maintenance), but they can handle higher volumes and larger parts and also don’t generate any waste. In some cases, the lack of waste balances with the higher maintenance cost to actually be about the same net cost as a cold-runner system.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly