Upmold: Plastic injection mould maker | plastic injection ... - plastic injectio

Author:gly Date: 2024-10-15

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

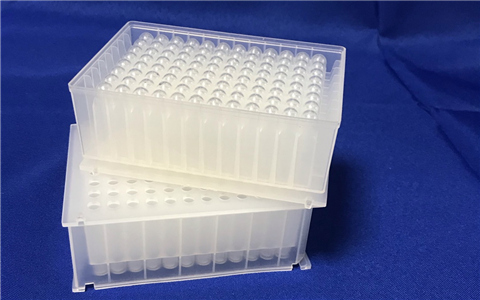

The demand for micro-injection molding products in the medical field is growing rapidly. SeaskyMedical addresses your needs with excellent micro injection molding capability. We have imported medical micro injection equipment, specializing in the production of micro products ranging from 0.1g to 0.5g. As well as that, our product wall thickness can be as thin as 0.2mm.

Overmolding involves two processes in the production line, which increases the part’s cycle time. When you need to mold a single item in a single operation, the production cost tends to rise. Furthermore, because overmolding is a two-step procedure, it necessitates the use of additional equipment than single molding.

The plastic injection molding is carried out, ensuring that we fulfill your order using the approved prototype and following the agreed lead time.

Although the technique enhances product performance, there are some downsides involved in its use. They include the following:

Once the substrate is in the cavity, the molten secondary material (overmold) is molded onto or around the substrate. After cooling, the overmold and the substrate become mechanically or chemically bonded to give the end product.

Overmolding eliminates the need for adhesives and fasteners since separate pieces can merge. As a result, the products’ durability improves. There is also a reduction in total production costs.

Seaskymedical is an ISO-certified medical injection molding company that manufactures injection molded plastic devices that are used in the medical industry. We make use of certified raw materials and carry out the production, assembly, and packaging processes in our ISO 8 cleanroom using reliable injection molding machines. Afterwards, they are put through stringent inspection to ensure that they meet the industry standards.

Therefore, this article aims to give a detailed overview of overmolding and two-shot molding, helping you understand their various differences. We will also discuss the benefits and drawbacks of these techniques. At the end of this article, you will be able to decide on the best molding services for your applications.

We offer various secondary operations including machining, ultrasonic cleaning, liquid filling and sealing, as well as shrink-wrapping

In the medical field, product quality represents its safety in use. SeaskyMedical always keep this in mind. We follows the quality management system for international medical device manufacturers, and have been certified by ISO 13485:2016.

Seaskymedical is highly-rated among the medical device injection molding companies for manufacturing custom injection molded products used in the medical and pharmaceutical field. We complete your bulk order of plastic medical molded products efficiently, and are able to meet the strict regulatory guidelines that medical applications require.

Injection molding has proven to be incredibly valuable for the fast and precise creation of high-quality plastic parts. It is a practical choice for a wide range of applications for various industries. However, different processes fall under the umbrella of injection molding. Two of the most popular techniques in this category are two-shot molding and overmolding.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

This article covered two-shot molding vs. overmolding, detailing the steps involved in the two techniques. These injection molding techniques are ideal for creating functional and aesthetically pleasing components for various industries. The various benefits and downsides of the processes will help you make the right selection for your project.

The extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector.

SeaskyMedical has rich material knowledge and can deal with a wide range of medical-grade plastics. Also, with our ISO 13485:2016 certified cleanroom and micro injection molding capability, we can meet the stringent cleanliness criteria and tight tolerance of the medical field.

It is important to note that the method of transferring the substrate can affect the speed of 2-shot injection molding. Manual transfers or the use of robotic arms often take longer than transferring with a rotary plane. However, using rotary planes is more expensive and may be more efficient for high-volume productions.

This process is also referred to as multi-shot, double-shot, or dual-shot molding. This injection molding process involves the molding together of two separate plastic resins in a single machining cycle. As a result, engineers can easily create multi-material and multi-colored parts without extra machining steps.

On the other hand, overmolding is best suitable for low-volume production. It is also ideal for rubber parts that do not have strict tolerance requirements. Overmolding services can be done on standard injection molding machines. Therefore, this technique is a great choice for manufacturers that do not want to invest in new machining tools.

Mold design may affect the ease of bonding between the molding materials. Therefore, machinists and engineers must ensure the correct alignment of molds to ensure easy adhesion and prevent defects.

RapidDirect is ready to work with your team to choose the suitable technique for your project. Our injection molding services are ideal for prototyping and production for applications in various industries. We assure fast turnarounds of high-quality products are competitive prices. Upload your CAD files today to get an instant online quote.

The two-shot injection molding process consists of two phases. The first phase is similar to the conventional plastic injection molding technique. It involves injecting a shot of the first plastic resin into the mold to create the substrate for the other material (s) to be molded around. The substrate is then allowed to solidify and cool before transferring to the other mold chamber.

To ensure optimal cleanliness and safety of our products, all manufacturing processes, including assembly and packaging are carried out in our class 7 & 8 cleanroom.

The second phase involves the introduction of the second material. Once the mold opens, the part of the mold holding the substrate will rotate 180 degrees to meet the injection molding nozzle and the other mold chamber. With the substrate in place, the engineer injects the second plastic resin. This resin forms a molecular bond with the substrate to create a firm hold. The second layer is also allowed to cool before ejecting the final component.

Like the two-shot molding process, the overmolding process also starts with the molding of the substrate. Although the substrate can be any kind of material, it’s best to use the more rigid material as the base. The next step involves placing the substrate in an overmold cavity within the same molding tool.

Manufacturers who require innovative product design, ergonomics, and a distinctive product appearance are all fans of plastic injection overmolding. The overmolding method has evolved over time, resulting in high customer satisfaction.

2-shot molding allows the combination of different materials and colors for functional and attractive final products. There are many possibilities available with this process, including:

When discussing two-shot molding vs. overmolding, it is pretty easy to confuse the two processes. They share several similar characteristics, and they offer similar benefits in manufacturing. However, there are major distinctions you must note to get the best results. The difference between two-shot molding and overmolding will help you choose the best option for your projects.

Knowing the comparison between overmolding vs. two-shot molding may not be enough. Working with a skilled and experienced manufacturing partner like RapidDirect will streamline your decision. We boast a team of designers, engineers, and machinists with many years of experience. Our expert teams are ready to see you through every part of the production process, from design to process selection and final manufacturing.

The medical industry has extremely high requirements for product production. To minimize the environment impact on products and improve product quality, it is very necessary to manufacture in a dust-free workshop. SeaskyMedical invests and establishs our own ISO 8 cleanroom, which has passed the ISO 13485 certification.

Seaskymedical is an all-in-one medical molding company. We are capable of handling all your medical plastic injection molding projects

As a professional injection molding company in the medical field, SeaskyMedical provides our customers with comprehensive services and support.

When two separate pieces are fused together in a mold, there is a danger of delamination. Delamination will occur when the ideal temperature range fluctuates. Mechanical interlocks are required when the available heat cannot properly fuse the materials.

Overmolding injection molding is a vital industrial process with many diverse applications. Some of the uses are highlighted below:

Remember that 2-shot injection molding is best for high-volume production while overmolding is ideal for low-volume production runs. Contact us at RapidDirect today, and let’s discuss your injection molding project.

Thanks to our experienced workforce, we’ve been in operation for over a decade, satisfying the exact needs of both small and big medical institutions. You can trust us to fulfill your medical injection molding projects according to your specifications.

All the necessary tools needed to make your custom mold are available. Also, we have specialized experts who are proficient in fabricating the right mold for your needs.

Such combination possibilities solve not only production difficulties but also the ability to produce components for applications in different industries.

Double-shot molding is ideal for complex, multi-material, and multi-color products. It is a highly versatile method, useful for many applications in different industries, including:

At Seaskymedical, we assist in providing you with excellent medical injection molding solutions for a wide array of medical products.

We can’t discuss overmolding vs. two-shot molding without mentioning their advantages and disadvantages. Although these processes are essentially similar, there are peculiarities you must look out for.

In addition to being a certified medical injection molding company, we have in-house experts and cutting-edge machines that improve the production of your medical injection molded products. Our capabilities extend to all forms and stages of medical plastic molding manufacturing, including product design and development, material selection, mold making, injection molding, and secondary operations.

We have ISO 13485:2016 certificate, guaranteeing the safety and reliability of our products. All our productions are done in compliance with the regulatory standards in the medical industry.

Our customers enjoy quick delivery time as we make use of advanced injection molding machines to fasten and strengthen production processes. Also, we have a professional manufacturing team that ensures that customers receive their order within a short lead time.

Two-shot injection molding involves in-depth and careful designing, testing, and mold tooling. Initial designing and prototyping may be done via CNC machining or 3D printing. Then the development of mold tooling follows, helping to create replicas of the intended part. Extensive functional and market testing is done to ensure the efficiency of the process before final production begins. Therefore, the initial costs involved in this injection molding process are usually high.

If you want to produce high-quality machined parts with a sleek appearance, it’s essential to consider some critical factors related to CNC machining.

Overmolding, an injection molding process of coating equipment with several materials, is very popular in the medical industry. For better rigidity and toughness of plastic medical devices, we carry out overmolding processes. Your plastic medical devices will be more robust and there will be no need for glue.

Two-shot molding and overmolding are simple but effective molding processes, helping to create durable, high-quality components. However, there are times when you may need to compare two-shot molding vs. overmolding to ensure you get the best result.

Gain in-depth related knowledge through our blogs. Or view our cases and see how we solve problems with robust injection molding capabilities.

However, design teams and engineers must evaluate critical considerations against their project requirements. This way, you can ensure the benefits outweigh the risks and make the best choices.

Two-shot molding is ideal for larger production runs, considering the difference between two-shot molding and overmolding. A significant drawback to the 2-shot injection molding process is the higher initial costs and expensive tooling. Therefore, it will be better to choose this process for larger productions. It is also great for flexibility, control, quality, and efficiency.

We provide you with 3D prototypes, allowing you to check while we make the necessary corrections until you are satisfied.

Overmolding is another multi-shot injection molding technique that creates an end product from two or more plastic materials. This process is applicable to various manufacturing and industrial uses. It is ideal for building high-quality functional and aesthetically pleasing components. Many manufacturers also use this method for plastic prototype development and to produce sub-sections of components.

SeaskyMedical focuses on the development and production of medical injection molded products. We assisting you in all stages, including product design and development, mold design and building, material selection and injection molding.

Although it is a two-phase process, it uses only one machining cycle. Within the single cycle, the initial mold is rotated out of the way, giving room for the insertion of the second molding material. With just one cycle involved, two-shot molding involves fewer costs and labor requirements. It also creates more items within a short period.

As a professional medical molding company, we provide our customers with comprehensive services and support in manufacturing their medical devices, as well as meeting the strict cleanliness standard and tight tolerance of the medical field.

Below are a few of the reasons why you should choose us as your medical molding manufacturer amongst other medical molding companies.

Some products may require two or more overmolds. An important point to note is that the plastic resins used in overmolding must be thermally or chemically compatible with one another. Incompatibility between the substrate and overmold may give a poorly bonded or deformed product. Sometimes, plastic resins can also be molded over metal substrates. In this case, compatibility may not be a big issue.

This process improves the product’s performance, including shock and vibration reduction, chemical resistance, and electrical insulation. TPE is one such material that, when employed to make various items, produces a non-grip feature. It can also operate as an environmental barrier due to the abovementioned qualities.

With this technique, designers have more freedom for innovative designs. The process can accommodate complex mold designs, incorporating multiple materials and making parts with complex geometries.

Seaskymedical has extensive expertise with medical insert molding used in making a plastic embodiment for metal and fragile medical devices that need better grip. With this, your hands will maintain a perfect grip on them no matter the condition they are exposed to.

Overmolding necessitates the assembly of several materials. This enhances the part’s flexibility by utilizing all of the capabilities of the materials involved. Furthermore, manufacturers can boost flexibility by using the overmolding design guide.

The two-shot process follows the traditional injection molding rules. Therefore, aluminum or steel injection molds are still used in this process, making design iterations quite difficult. Reducing tool cavity size may be difficult and sometimes result in scrapping the entire batch of product. As a result, you may be incurring cost overruns.

Overmolding is excellent for creating aesthetically appealing structures. It is the best approach since it is available in a range of colors and materials. They may also be modified for other surface finishes to improve their cosmetic appearance further.

The tooling involved in this technique is complex. There is also a need to remove previous materials from the machine before the next production run. As a result, setup time may be quite long. Therefore, using the two-shot technique for small runs may be too expensive.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly