Understanding ABS Injection Molding - abc plastic molding

Author:gly Date: 2024-10-15

In the medical industry: In a lot of cases, medical instruments are needed for specialized uses and will require a few hundred parts and accessories to be produced. It is perfect to use the short run molding for low production runs with high product quality.

Usefulness in the military and aerospace industries: The military and the aerospace industries are very similar to the medical industries. Unlike many fast-moving consumer goods (FMCG) industries, these industries do not always require a large volume of parts and products. In this case, they rely on short run molding to produce a limited number of accessories and parts.

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

It can accommodate a wide range of material options: When it comes to resin options, there are no limits to using short-run molding. There are thousands of available resins that you can use for this production process. In addition, you can also apply the resins used for higher volume molding for this production process.

JunoPacific is a custom medical device design, development, manufacturing and assembly operation located near two major medical device hubs: San Jose, CA and Minneapolis, MN.Manufacturing custom plastic products for multi-national fortune 500 medical compa...

automotive injection molding companies Best Top 5 Low Volume Injection Molding Companies china low volume injection molding contract manufacturing low volume Custom Low Volume Plastic Parts Manufacturing custom plastic injection molding china injection moulding of liquid silicone rubber Low-volume injection molding cost low-volume manufacturing china Low Volume Injection Molding low volume injection molding canada low volume injection molding companies low volume injection molding company low volume injection molding europe low volume injection molding in usa low volume injection molding manufacturers low volume injection molding services low volume injection moulding uk low volume low cost plastic injection moulding low volume manufacturing low volume manufacturing companies low volume manufacturing processes low volume manufacturing service low volume manufacturing services low volume manufacturing strategies Low Volume Plastic Injection Molding low volume plastic manufacturing low volume plastic parts low volume plastic parts production low volume production plastic parts low volume production sheet metal low volume silicone molding metal pressing in low volume production plastic injection molding manufacturer plastic molding low volume production pvc low volume manufacturing mold custom factory online Short Run Injection Molding short run injection molding cost short run plastic injection molding small batch injection molding small batch plastic manufacturing small plastic parts manufacturer small quantity injection molding small volume manufacturing small volume silicone manufacturing

We usually run into injection molded products in different stores at all times. Such products are often from big companies that make a high number of these products every year. Every year, they make use of injection mold technology to create a large volume of products. In some cases, they make millions of these products every year to be distributed across the world. This shows that this production model is suitable for large production runs. But what if you want to produce a new product in a few thousand or less? What if you want a low-volume on-demand production process that requires less time and costs? All of these objectives are possible when you use “short run plastic injection molding”. For many people, this is a relatively new process that comes with its advantages.

Our V70 controller supports OPC-UA communication standards. This capability along with our machiNet IoT+m platform allows machine and process data to be remotely monitored and shared with plant MES and ERP system. Contact your Shibaura Machine representative today to discuss your specific requirements.

Yes. Dial xxx-xxxx-xxx- for service. Outside of normal business hours, you can leave a message and an "on-call" technician will call you back.

Used for producing limited edition cars and vehicles: Short-run injection molding is used extensively in the production of exotic cars. Many exotic cars are built in very few numbers. This is because it costs money and time to put them together. They are produced by using short run injection molding technology. This molding system can be used to ensure high quality as well as bespoke aesthetics.

We have provided precision injection molding machines to the North American market since 1974 and have an installed base of over 15,000 injection molding machines. Our global manufacturing and world-class engineering capability, along with our long heritage of industry leading innovation, reliability, and precision, continue to make us the most proven and reliable partner for your injection molding machinery needs.

Production of trial parts and prototypes: There are certain cases where you need more product samples and you can’t just fully rely on the 3D printing machine. When this is the case, you can rely on short run molding to produce more samples for you in less time. This is a lot better than using 3D machines for prototyping which can be greatly limited.

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

With over $8 million in injection molding machine spare parts inventory and 4 parts associates on duty, we're set up to get you the parts you need quickly and efficiently.

Produce goods of high quality: People often think that short run molding cuts corners and does not offer accurate dimensional tolerances as well as quality. However, the fact behind this production process is that it offers very high dimensional tolerances. It also provides excellent surface quality while also supporting high-volume injection molding processes. It offers exceptional quality when it comes to fitting different parts together.

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with an ECSXIII machine, the understanding of sub screens and general screens. Students will have hands-on training on an ECSXIIIV70 machine. Click here to download the class synopsis.

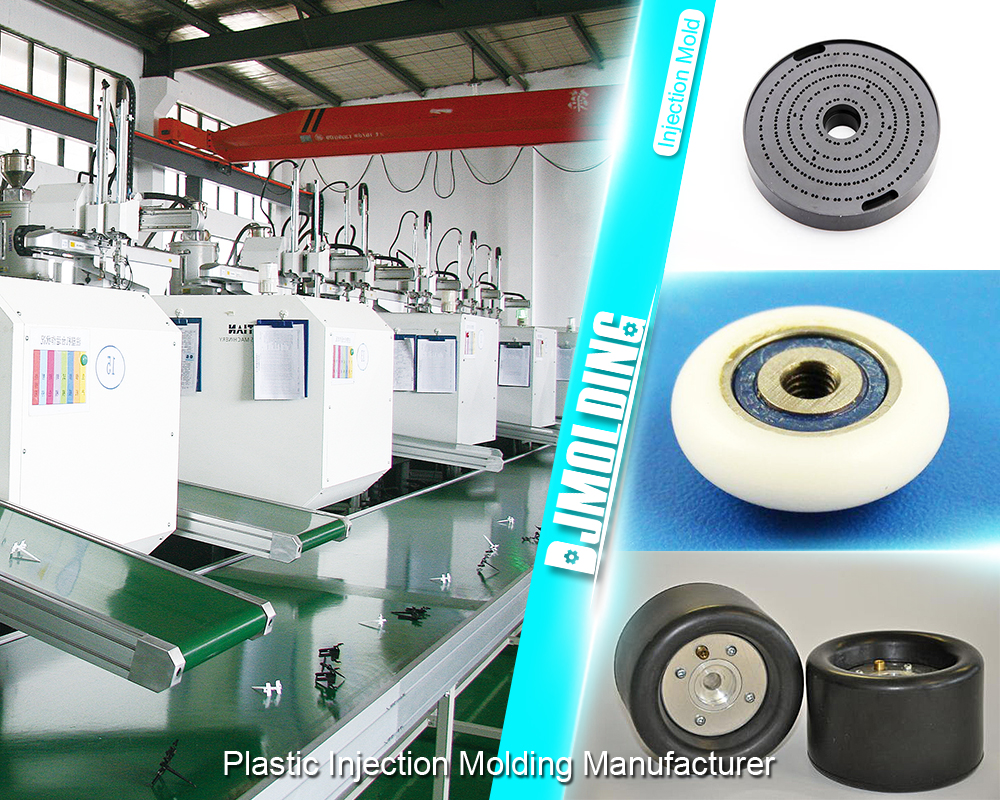

Djmolding is plastic injection mold maker in china,as a china plastic injection molding manufacturer supplier factory,we supplying high-precision plastic injection products,low volume injection molding for low volume manufacturing service,high volume injection molding,quick-turn injection molded parts and so on.

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with an ECSXIII machine, the understanding of sub screens and general screens. Students will have hands-on training on an ECSXIIIV70 machine.

For more about what is short-run injection molding as an industrial process,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-manufacturing-service/ for more info.

Founded in 1953, Hoffer Plastics has grown to become an industry leader and innovator in the custom plastic injection molding industry. Located in a 365,000 sq. ft. facility on 24 acres and employing more than 350 people, they produce more than three bill...

Our North American headquarters, centrally located in Elk Grove Village, IL, is fully equipped to support sales, service, parts, mold trials, and customer training. Our service offices in Elk Grove Village, IL, Rancho Cucamonga, CA, Charlotte, NC, Markham, ON, Canada, and León, Guanajuato, Mexico are staffed with experienced, professional service technicians who are fully committed to supporting the success and profitability of our customers.

We continue to actively monitor and adopt to CDC guidelines, as well as those issued by federal, state, and local authorities to keep our staff, customers, and business partners healthy!Attached for your reference is a letter from our President and a hando...

Does not need any minimum order requirements: High-grade steel molds are used for larger production runs. However, if you are looking to produce several hundreds of certain materials, you don’t have to pay for a minimum amount of products. Simply use the short run injection molding process to mold as many products as you want. In this production system, you are not restricted by any volume requirements.

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with an ECSXIII machine, the understanding of sub screens and general screens. Students will have hands-on training on an ECSXIIIV70 machine. Click here to download the class synopsis.

It calls for low initial costs: Higher-grade aluminium or lower-grade steel costs less when compared to that of the high-grade steel needed for large production runs. Certainly, high-grade steel can be used to produce thousands/millions of parts, but short-run injection molding is more suitable for low-volume production.

We use cookies to personalize content and ads, to provide social media features, and to analyze our traffic. We also share information about your use of our site with our social media, advertising, and analytics partners. View our Cookies Policy to learn more about how we use cookies and how you can manage them.

Our 5 North American service offices and 35 injection molding service employees are here to help support the success and profitability of our customers.

Yes, in most cases auxiliary equipment can be integrated with our machines. Speak to your Shibaura Machine representative for more details.

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

Performance Gear Systems was founded in 1997 with the mission to be a world leader in the design, engineering, and manufacturing of high precision plastic gears and actuators. Located in Plainfield, IL, this 50,000 square foot cutting-edge facility brings ...

Short-run injection molding is used commonly for the production of high-quality goods. A lot of niche industries rely on this production process to create a low amount of products and accessories each year. It can be used in various ways such as:

Elk Grove Village, IL - April 16, 2020 – Shibaura Machine is proud to work with our customers who have been deemed “essential manufacturers” during the current COVID-19 crisis. We continue to ship out machines being used to make Personal Protective Equipm...

Shibaura Machine generally stocks over 100 injection molding machines in our North American inventory for quick delivery. Our U.S. assembly facility allows us to quickly customize molding presses to our customer’s specifications. Capabilities include powering up machines for test runs, installing software updates, installation of special options, and machine inspection before shipment.

This 1-1/2 day class will include the review of the proper maintenance procedures for Shibaura hydraulic machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. A Shibaura all electric machine will be used in process demonstration in conjunction with classroom training.

New Berlin Plastics was founded in 1975. After two company moves in 1976 and 1982, business continued to expand, allowing NBP to transition to a new 100,000 square foot facility in 1998. This facility is located in New Berlin, Wisconsin and serves as the...

Yes, we offer a variety of training classes including Processing, Controls, and Maintenance. Classes are held in Elk Grove Village, Illinois, Ontario, California, Charlotte, North Carolina, and Markham, Ontario Canada.

ELK GROVE VILLAGE, IL April 1, 2020 – Effective April 1, 2020, our company name changed from “Toshiba Machine Company, America” to “Shibaura Machine Company, America.” We started business as a machine tool manufacturer in 1938 under the Shibaura name, and...

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with a V50 Controller, the understanding of sub screens and general screens. Students will have hands-on training on a V50 Controller. Click below to download the class synopsis.

Short run plastic injection molding is a production process that is also known as small batch or low-volume injection moulding. This production process requires reduced capital and a shorter time to develop. This molding system is used for the production of simple plastics through high-grade aluminium or low-grade steel injection molds. High-grade steel injection molds are used in large-volume plastic production runs. The short-run plastic injection molding is best suitable for injection molding production that needs less than 10,000 parts to be produced.

It helps to reduce the overall production time: Short-run injection molding helps increase the turnaround time of parts production by a matter of weeks or days. This usually depends on how complex the mold designs are. This is highly beneficial in comparison to high-grade steel molds which usually take months for production to be completed.

There are many short run injection molding companies around. However, you need to choose the best option. A reliable injection molding company will offer you all the benefits of this type of molding as we have highlighted above. Many such companies have a great deal of expertise in short-run projects. Additionally, these companies may offer similar production solutions with the use of 3D and CNC machines. This is because all these machines can be used for supporting or complementary services during an injection molding project. This is necessary because, in reality, many of these production systems are used to support each other. Then again, they are more suitable for specific projects that may not require the use of any other production technology. A reliable manufacturing company will provide the best short-run injection molding services. They will also help their customers solve the different problems as seen in short run injection molding systems. It is common to use a manufacturer that has completed thousands of injection molding projects for different customers.

The U.S. Injection Molding Div. of Shibaura Machine completed its move into a 58,000 square foot facility in Elk Grove Village, Ill., replacing a a smaller facility in Elgin, Ill. The new plant consolidates the plastics sales, service and assembly function...

Huizhou Djmolding Co., Ltd, established in 2010, is a leading plastic injection moulding and mould manufacturer in China. Djmolding is a low volume manufacturing companies specializes in plastic mould and plastic parts production for household appliances, medical equipments, electronic equipments, safety equipments as well as monitoring system.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly