Third Party Manufacturing Company for Injection - injection manufacturing compan

Author:gly Date: 2024-10-15

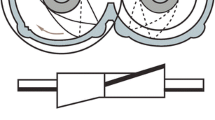

To mold plastic products, the plastic is plasticized, that is, it is melted. The plasticator is the device that does so. Different methods can be used. The common types are those found in the single-stage (or reciprocating) and the two-stage IMMs (Chap. 2). In the reciprocating type, plastic is fed through a screw and into a shot chamber (front of screw). In the two-stage plastic is fed into the first-stage screw, where it is plasticized prior to entering the second stage. In the first-stage plasticator the screw motion generates controllable low pressure [usually 50 to 300 psi (0.34 to 2.07 MPa)], which causes the screw to retract slightly, preparing the melt to enter the second stage. Depending on the plastic’s melt flow characteristics and pressure required in the mold cavity or cavities, the injection pressure at the nozzle is between 2,000 and 30,000 psi (14 and 200 MPa). Adequate clamping pressure must be used to keep the mold from opening (flashing) during and after the filling or packing of the cavities with the plasticized melt.

While the number of different plastic devices and components used in the medical industry and dental industry seem nearly infinite, there are a variety of “usual suspects” in constant high demand among injection molding manufacturers, including the following:

The process that results in finished, high-quality plastic medical devices and related components requires a number of key pieces to be in place. In the product design phase, the device or part must be conceptualized with design engineers to determine essential specifications and parameters, including intended use. Early on in this process, choosing the right plastic material for the project is critical—and there are thousands from which to choose.

The above is just an overview of a small sample of plastic resins available for use in the injection molding process for medical and dental devices. Rest assured the experts at Global Plastics will know which plastic material is the best option for your specific project.

Rosato, D.V., Rosato, D.V., Rosato, M.G. (2000). Plasticizing. In: Rosato, D.V., Rosato, D.V., Rosato, M.G. (eds) Injection Molding Handbook. Springer, Boston, MA. https://doi.org/10.1007/978-1-4615-4597-2_3

Global Plastics has Safe Quality Food (SQF) certification for manufacturing food packaging materials and plastic molded food closures.

Applicable regulatory frameworks must be consulted, whether those of the FDA (U.S. Food and Drug Administration) or ISO 13485 standards related to medical devices, and whether clean room or white room manufacturing environments are needed.

The number of different plastic resins available today is staggering. Choosing the right plastic material is an essential step for any plastic medical device or component based on its intended application. Available plastic materials include the following:

With decades of experience in managing a diverse range of injection molding projects from beginning to end, Global Plastics invites you to learn more about our services. We work tirelessly to achieve cost effectiveness while maintaining the highest quality possible for every medical device, part, or component we produce. Our ability to efficiently deliver a solution that achieves the desired result is how we’ve built our reputation in this highly competitive industry with each customer client. We’d be honored to do it for your company as well. Use the contact us form on our website to learn more about our plastic medical device injection molding services.

The prototyping phase allows for short runs using a prototype mold (often tooled in aluminum) in order to ensure the product specifications are optimal before investing in the tooling of a steel production mold. Along the way we will have also determined which of our fleet of 70+ injection molding machines are best suited for full production runs of the plastic item. As a manufacturing process, custom injection molding is often the most cost-effective solution for many medical devices and parts.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly