The Best Plastics To Use In Injection Moulding - polyethylene injection moulding

Author:gly Date: 2024-10-15

We can engineer your moulds in the most cost effective way, from prototype to production. Whether it is a one off mould requirement or a long lasting business relationship, we aim to forge mutually beneficial business partnerships.

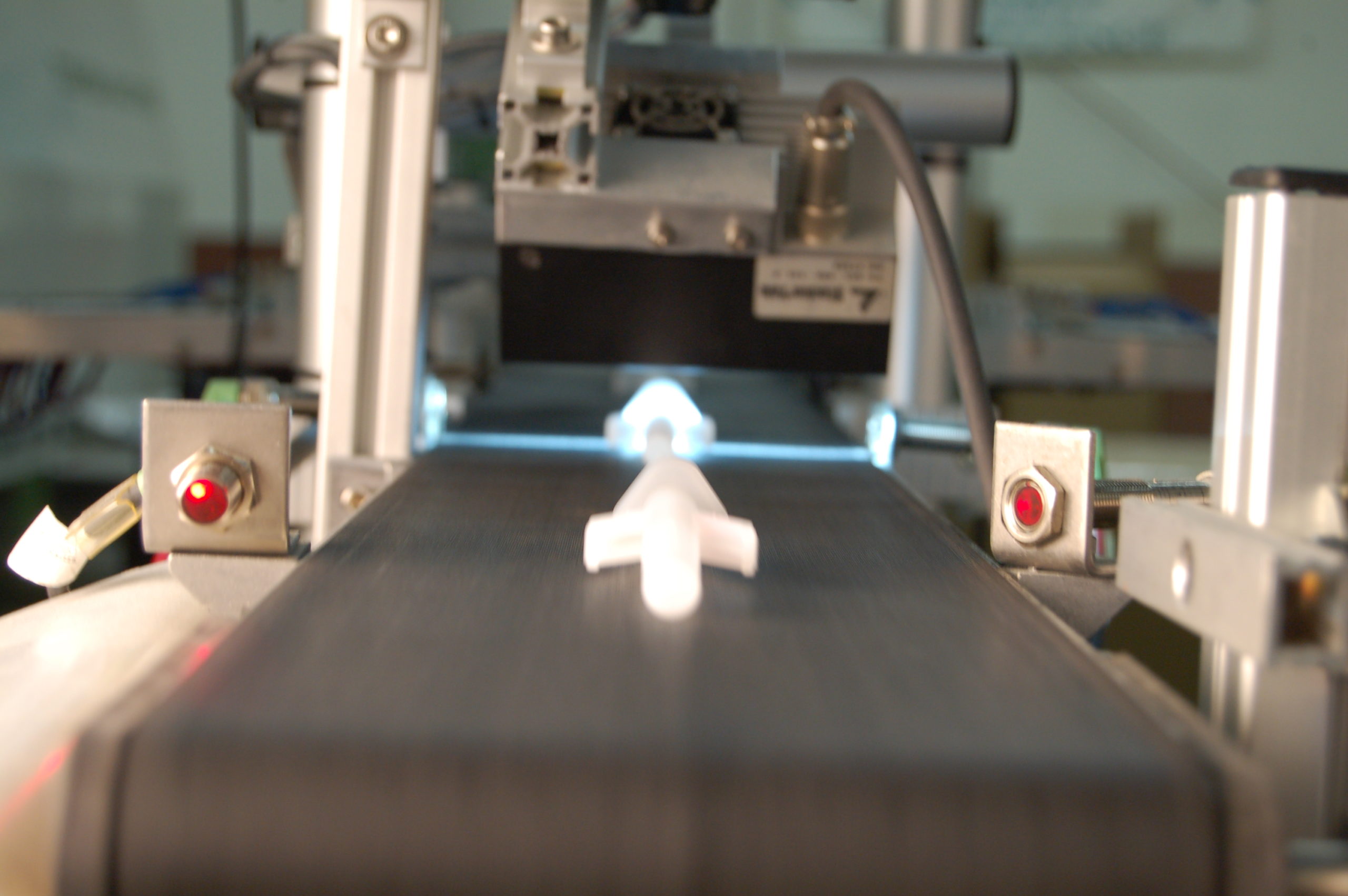

Plastic Injection Moulding is the process of injecting heated material into precision engineered moulds, producing products according to the material and colour selected.

Our medical plastic injection molding and clean room molding production solutions that increase quality, security and provide cost advantages for the Medical Market are:

Established in Belmont in 1985, S&G Precision have spread our client base over the farming, agriculture, medical, mining, electronics and building & construction.

For all enquiries, quotes and proposals, please contact us using the form below, or at the following details. 20-28 Hubert Street Belmont WA 6104 Ph: (08) 9478 3492

All-Plastics employs a state-of-the-art plastic injection molding process in order to produce high-quality medical products that meet the strict guidelines set by regulatory bodies. This ensures the safety and efficiency of all manufactured medical products and tools, which include:

Injection molding is one of the most widely used manufacturing processes, capable of producing intricate plastic parts with high precision. However, like any industrial process, it has its challenges, and…

Material selection and method of production are always key considerations in the manufacturing of products, devices, and components for the medical industry. This is because of the strict regulations and standards that govern the industry. Plastic injection molding meets these requirements and offers a wide range of benefits for the medical industry.

By employing advanced medical injection molding in our manufacturing process, we are able to supply high volumes of medical components without sacrificing quality while meeting your target specifications.

All-Plastics works with a variety of medical industries to provide injection molding services to help create, design, and mold custom applications and parts. Some of the medical markets we serve are:

Medical injection molding is a plastic molding and manufacturing process involving liquefied plastic into a mold to create plastic products of various shapes and sizes. In this process, the plastic is allowed to conform to the shape of the mold and harden to produce the desired finished product.

With the capability to produce product, ranging from 80 tonne to 650 tonne with a maximum shot capacity of 3.4kgs, S&G Precision want to work with you to bring your product to reality.

If your smartphone has a clear, durable casing, it's likely made of polycarbonate. This thermoplastic polymer is a popular material among plastic parts, components, and products manufacturers. Its qualities, such…

All-Plastics caters to your need for durable plastic medical components that comply with strict FDA standards and regulations.

All-Plastics has expertise in providing cost-saving, high quality injection molding solutions to the Medical Device industry. Our expertise in medical injection molding allow us to support tight tolerance micro-sized components to complete medical devices.

We have experience in many products using raw materials such as Nylons, Polypropylene and Polycarbonates and a range of engineering resins.

![]()

Our experts provide Project Management solutions from Concept to Operational Excellence, including full program documentation and component traceability. REQUEST A QUOTE

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly