Sussex IM on LinkedIn: #injectionmolding #plastic - sussex injection molding

Author:gly Date: 2024-10-15

Our multiple technology platforms combined with our innovative research and development team allow us to provide customers with a broad range of resins to meet the many specific needs of injection molding applications. Our world-class sales and marketing team and highly experienced technical support team can assist customers with resin selection, process optimization, application development, part and mold design, and outstanding training in-house or at our fully equipped Plastics Technical Center. The products below provide solutions to your injection molding application needs. For more detailed information, select the individual links for each product.

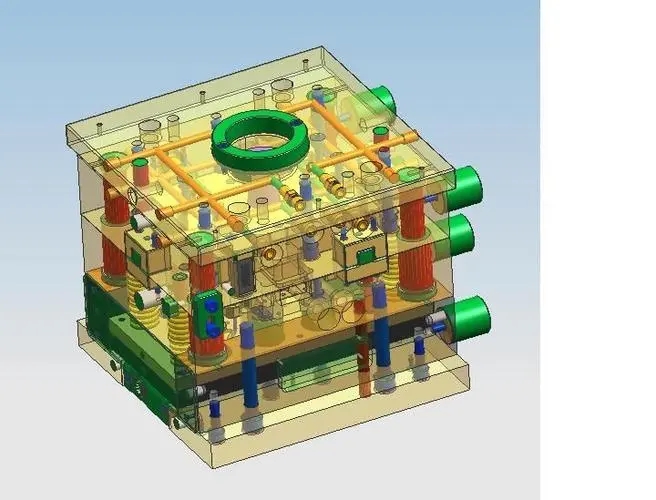

General definition of mold: in industrial production, various presses and special tools installed on the press are used to make metal or non-metallic materials into parts or products of the required shape through pressure. Such special tools are collectively referred to as molds.

The injection molding process is one of the most cost-effective processes to produce parts; it is used to make parts for practically every major industry existing today. Some of these industries include containers, food and chemical packaging, toys, automotive, crates, and caps and closures. We have over 40 years of experience with high-quality polymers, such as Marlex® polyethylene, used in the injection molding process.

In recent years, with the rapid development of plastic mold industry and the continuous improvement of strength and accuracy of general and engineering plastics, the application scope of plastic products is also expanding, such as household appliances, instruments and meters, construction equipment, automobile industry, daily hardware and many other fields. The proportion of plastic products is increasing rapidly. A reasonably designed plastic part can often replace multiple traditional metal parts. The trend of plasticization of industrial products and daily-use products is rising.

Our sustainability strategy encompasses the concerns and issues identified by our stakeholders and we are committed to addressing these issues.

Injection molding process description: mold is a tool for producing plastic products. It is composed of several groups of parts, and this combination has a forming die cavity. During injection molding, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding mold cavity, cooled and shaped in the cavity, and then the upper and lower molds are separated. The products are ejected from the mold cavity and left the mold through the ejection system. Finally, the mold is closed for the next injection molding. The whole injection molding process is cyclic.

All kinds of tools and products used in our daily production and life, ranging from the base and body shell of the machine tool to the shell of a embryo head screw, button and various household appliances, are closely related to the mold. The shape of the mold determines the shape of these products, and the processing quality and accuracy of the mold also determine the quality of these products. Because of the different materials, appearance, specifications and uses of various products, molds are divided into casting molds, forging molds, die-casting molds, stamping molds and other non plastic molds, as well as plastic molds.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly