Small-scale plastic injection molding - Marabuplast LLC - small scale plastic in

Author:gly Date: 2024-10-15

A third application of bi-material injection is to develop sealing functions with molding of joints directly on the part without the need for an assembly step after injection.

Specialist in plastic injection in China for more than 15 years. From the study to industrialization of parts and sub-assemblies, we can guarantee you secure, easy, qualitative and competitive cooperation.

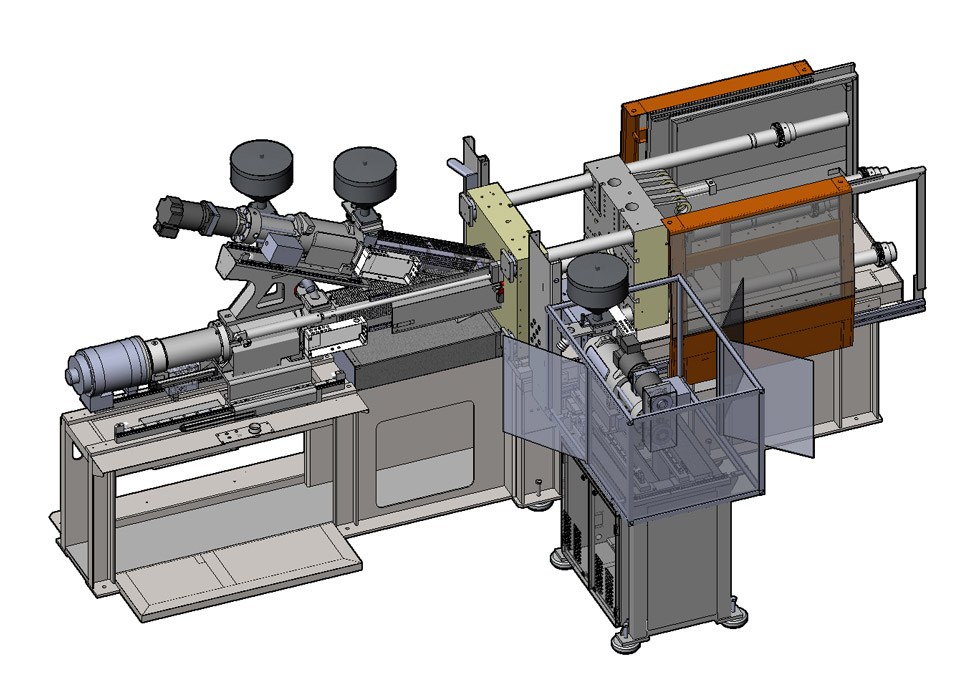

Our injection workshop is equipped with automated presses and is suitable for this type of process (up to 480 tones). Molds used for bi-injection are also manufactured in our in-house mechanical workshop.

We regularly produce all types of bi-material parts according to our customers’ needs. Below are 3 examples of parts we have produced, illustrating the 3 primary applications of bi-material thermoplastic injection:

Another application of bi-injection is injecting a material with another material to create a soft or grip effect in a functional gripping area (flexible or rigid material) – tactile grip effect on matte red.

Bi-injection uses a press equipped with a second screw and hopper to inject the complementary material at the same time. The definition of the parting line is generally validated during the part analysis phase.

More than just a plastics injection molding company, we assist our customers from the design to industrialization of their products. Depending on your specifications, we are able to intervene at different levels via our integrated service offer:

Nous utilisons des cookies pour optimiser notre site web et notre service.Conformément à vos choix, certains partenaires et nous pouvons accéder à votre terminal pour vous reconnaître via des traceurs comme des cookies, collecter, stocker, croiser, et transférer des données comme vos adresses IP et email, vos paramètres de logiciels, votre navigation ou votre localisation, à ces fins : Publicités standards et mesure de performance des publicités, Profil de publicités personnalisées et affichage, Contenu personnalisé et Mesure de performances du contenu, données d'audience, et développement produit.Nous vous en remercions et vous proposons d'appliquer vos choix à ces partenaires également. Vous pouvez bien sûr refuser leurs traceurs et traitements.

You will find below, several examples of customers who have entrusted us with the production of their plastic-parts and sub-assemblies.

FPM Injection, a French industrial partner has been a specialist in plastics injection molding in China for more than 15 years. Depending on your needs, we inject small and large series of technical and appearance parts. Located in the South of Shanghai, we have our own production plant (WOFE). Our company is a certified ISO 2009 and equipped with adapted and inspected means of production (single and bi-material injection presses, machining centers, assembly lines, etc.). It is a gage of confidence for our customers as we control internally, all steps of the manufacture of plastic parts and functional sub-assemblies.

In general, the process is fairly similar to conventional (single material) injection molding. The materials are brought to their melting point and then fill the mold cavities.

Nous utilisons des cookies pour optimiser notre site web et notre service.Conformément à vos choix, certains partenaires et nous pouvons accéder à votre terminal pour vous reconnaître via des traceurs comme des cookies, collecter, stocker, croiser, et transférer des données comme vos adresses IP et email, vos paramètres de logiciels, votre navigation ou votre localisation, à ces fins : Publicités standards et mesure de performance des publicités, Profil de publicités personnalisées et affichage, Contenu personnalisé et Mesure de performances du contenu, données d'audience, et développement produit.Nous vous en remercions et vous proposons d'appliquer vos choix à ces partenaires également. Vous pouvez bien sûr refuser leurs traceurs et traitements.

In single-material injection, resin is injected into a cavity and then, after an appropriate cooling time, the two mold halves are opened, and the part is ejected. In biomaterial molding, the two resins are injected into the mold. For this purpose, a space must be created in the mold to accommodate the additional resin. To do this, several bi-injection methods for tooling are available: transfer molds, molds with rotatory plate, molding with a rotating base, molding with core-back process.

Bi-injection molding, or 2k injection molding, is a plastic injection process allowing the production of a part made of two materials with different characteristics using a single press and a single tool. Examples of its use include parts requiring two colors or two different hardness levels. As a specialist in plastic injection molding, we’ve developed advanced know-how in dual injection molding of plastic materials.

Whether or not to use bi-material injection depends on various inherent constraints of your project and a preliminary study to validate your selection is generally required. Bi-injection is often used for large-volume production, complex geometries or in cases where over-molding is not suitable. Below we present some of the advantages and disadvantages of this process compared to mono-injection or over-molding:

Other applications are also possible, depending on the type of part and the specifications of your product. Bi-injection molding also allows the production of transparent parts comprising an opaque zone (colored or not) to create colorful graphics and elegant finishes that enhance product functionality and added value. It’s possible to create rigid zones with flexible zones: hinge effect, shock-absorbing zones, push buttons, etc.

Applications of bi-injection molding are quite numerous in a variety of industries such as household, cosmetic and electrical products and increasingly in the automotive sector.

Depending on the properties of the part and the project constraints, our team of designers and engineers is responsible for determining the most suitable solution for you from among these different tools.

– Reduced unit cost per part – Elimination of assembly step – Single production phase (reduced lead times) – Complex geometries possible – Improved integrity and durability

Do not hesitate to contact us to know more about our know-how in China. We are ready to listen to assist you in your plastics injection project.

As an expert in plastics engineering, we have great experience in thermoplastics parts injection, plastic over-molding and plastic molding. Multi-material, we transform any type of thermoplastic and elastomer materials; multi-sector, we produce for very varied business sectors (automotive, medical, sports, electronics, sectors, etc.) on all types of plastic parts.

This solution can be advantageous (in time and cost terms) while also satisfying very precise constraints. Bi-material injection molding involves a certain technicality and requires good mastery of tool design, materials selection and the injection phase itself. For this reason, we can support you upstream of your project to guarantee that it remains feasible and viable.

Specialist in plastic injection in China for more than 15 years. From the study to industrialization of parts and sub-assemblies, we can guarantee you secure, easy, qualitative and competitive cooperation.

Before including a bi-injection solution in your specifications, please contact us to determine that it is feasible and cost-effective. Our internal organization allows us to support you in your analysis since we benefit from having a design office and mechanical workshop in house.

– Feasibility study – Part analysis – In-house tooling design and development – Mold flow analysis – Machining of tools – Testing and validation – Series production

A very common application of the bi-injection process is to produce parts made of two similar materials but with different masstinted colours – in this case, creamy white with red.

Our primary vocation is, in fact, to supply our customers with competitive and easy to use plastics sub-contracting by means of:

In general, all thermoplastic polymers, from the simplest to the most technical, are compatible with the bi-injection process. In the case of flexible materials, the over-molded material is generally SEBS/TPE (Styrene-ethylene-butylene-styrene) or TPU (thermoplastic polyurethane) with different Shore hardnesses and possible textures. Most often, the two assembled components are different but similar and show good chemical compatibility.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly