Short-Shot Plastic Injection Molding Issues: How to Diagnose - short mould in in

Author:gly Date: 2024-10-15

Food, beverage and consumer products industries rely on PET for many of their packaging needs. Among the common applications are:

PET’s popularity among PET injection molding manufacturers and their customers is a result of the availability of the materials and relatively low cost. In addition, PET is:

Hi-Tech has an excellent customer service and high quality products. Hi-Tech supports us with our Kanban program to have product on time. Support team is always available for us to answer all our questions.

Hi-Tech produces components and assemblies in a wide range of Engineered Thermoplastics, verifies lot traceability and can aid in material selection during design or supply issues.

Consumers commonly find PET as the material used in plastic jars, convenience packaging and plastic bottles, including those used for carbonated beverages. In the 60 years since it was first introduced, PET has become one of the most widely used and most sustainable plastic materials in the world. Interested in using this material for your project? Request a quote to get pricing.

Although it looks and feels like PET, PETG (or copolyesters) is a modified PET, produced by adding a second glycol during polymerization. PETG removes the hazing that can impact PET and reduces the crystalline effect that can cause PET to become brittle. PET plastic injection molding machines can use PETG to produce bottles that are softer and more pliable for a more comfortable grip. PETG offers clarity, toughness and stiffness and is used in medical test tubes and bottles, lighting fixtures and appliances. The material’s benefits come with a higher cost than the cost of PET.

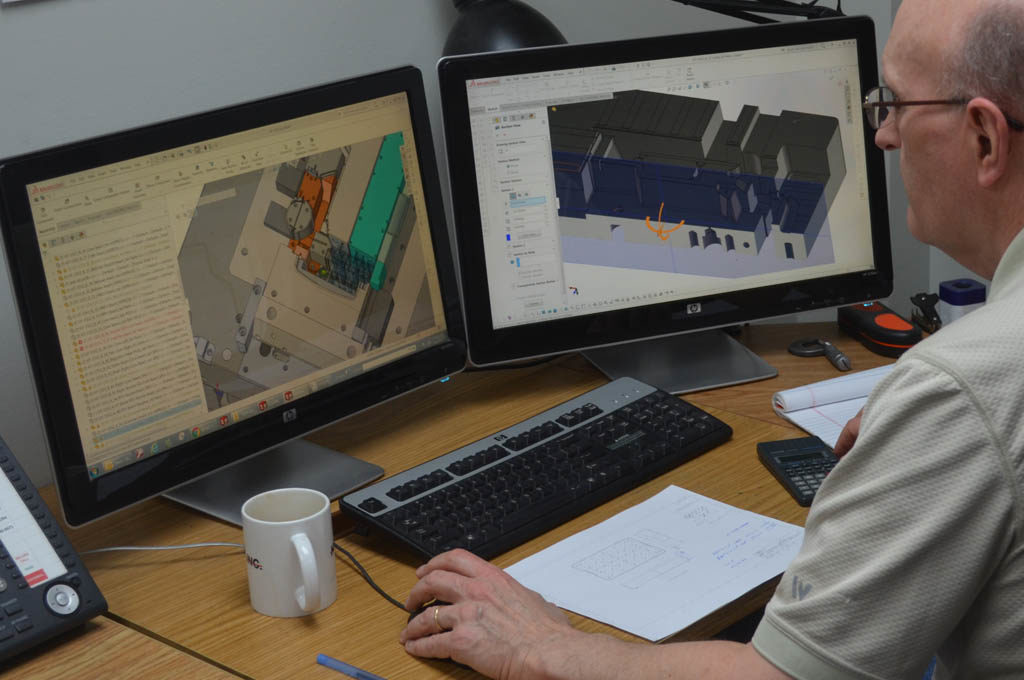

Hi-Tech produces molds in-house and can source molds from Overseas. The tool room allows us to maintain consistent part delivery performance.

PET was first polymerized for use as textile fibers known as polyester. Today, PET injection molding manufacturers utilize the material to produce strong, lightweight packing.

Hi-Tech can evaluate 3D Models and 2D Prints to help optimize the Part Design for Molding and to help identify potential issues.

A member of the polyester family, PET is the synthesis of ethylene glycol and terephthalic acid. The addition of glycol produces PETG, widely used by PET injection molding manufacturers in plastic injection molded bottles and containers.

Over 30 years ago Bill Kristensen Sr. started Hi-Tech, with the goal to create a full service facility that could support customers from mold builds, molding, machining and all post molding/machining operations. We have developed proprietary manufacturing processes for high-temperature molding, thus becoming a unique resource for cost-effective metal substitution. We are experts in advanced thermoplastic materials, our service model is stronger than ever.

I have been working with Hi-Tech for 5 years now. Over that span, Hi-Tech has always been very easy to work with and they present themselves in a professional manner. Hi-Tech has delivered quality injection mold tooling and parts with competitive pricing. Their Program Management and Engineering group kept up with several design changes throughout the tool build and still delivered on-time.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly