Scientific Molding Pocket Guide | Injection Molding - scientific molding

Author:gly Date: 2024-10-15

Blow Molding involves inflating hot thermoplastic inside a closed mold, and is used to produce hollow plastic parts. Our Blow Molding capabilities include stretch blow molding, injection blow molding, and extrusion blow molding. We utilize a wide range of thermoplastic raw materials for the molding process.

Lomont Molding, LLC is a premier plastic molder offering complete in-house services including engineering, tooling, in-mold technologies and decorating, quality assurance, and assembly and secondary operations. We have been in business since 1982 and process various types of thermoplastic resins in our state-of-the-art manufacturing facility.

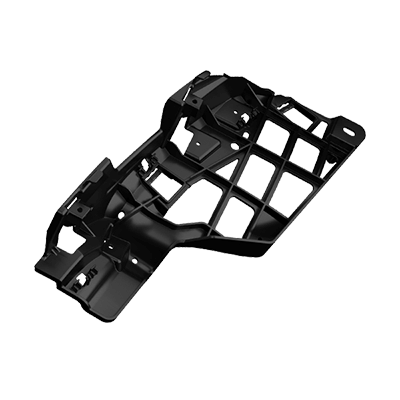

Knauf Industries Automotive as a plastic injection molding manufacturer and supplier, specializes in thermoplastic injection molding technology. Our know-how also comprises gas injection molding technology, high gloss and e-moulding. Our injection moulded exterior and interior car components for the automotive industry are predominantly engineered out of the following materials: - polystyrene (PS), - polypropylene (PP), - ABS, - PC, - PC / ABS, - PC / PMMA.

Lomont provides secondary operations and assembly services to prepare your product for distribution including: painting, shielding, balancing, date coding, labeling, post-production bending, part assembly and packaging.

To the dynamic automobile industry we are a reliable partner in production of a variety of injection molded interior components. In our ISO IATF accredited factories we carry out interior component projects for the leading automotive manufacturers. We are experienced OEM, Tier 1 automotive supplier and manufacturer of automotive interior and exterior trim parts. Our product portfolio of interior injection molding components comprises plastic auto parts such as: dashboard elements (e.g.: glove compartment, door and window pillars), steering column trims, door handles, air vents, centre consoles, roof modules, etc.

The Gas Assist Injection Molding process uses nitrogen gas to create lightweight plastic products that have a superior surface appearance. Since the gas disperses evenly throughout the mold, the process can be used to create thin-walled parts that can be formed to a high standard of flatness without sacrificing strength and durability.Lomont Molding is a diverse company where people are the foundation. As a company, we reject discrimination. Anyone who knows our company, knows this. We value our customers, suppliers, employees, along with our communities where we are actively engaged.

©2017-2024 Lomont Molding LLC • Corporate Headquarters • 1516 East Mapleleaf Drive • Mt. Pleasant, Iowa 52641 Phone: 1-319-385-1528 • Fax: 1-319-385-1555 info@lomont.com

To the dynamic automobile industry we are a reliable partner in production of a variety of injection molded interior components. In our ISO IATF accredited factories we carry out interior component projects for the leading automotive manufacturers. We are experienced OEM, Tier 1 automotive supplier and manufacturer of automotive interior and exterior trim parts. Our product portfolio of interior injection molding components comprises plastic auto parts such as: dashboard elements (e.g.: glove compartment, door and window pillars), steering column trims, door handles, air vents, centre consoles, roof modules, etc.

Extrusion is used to create plastic products with a continuous cross-section such as pipes and decorative molding. Plastic extrusion uses raw thermoplastic beads that can be enhanced with custom colors and UV inhibitors, and is a versatile molding process that is inexpensive and can be used for a wide range of applications.

Ask your question in a 1 on 1 enquiry and we will give you a detailed answer, whatever the country/region you need our support.

Our high pressure plastic injection molding process is ISO 9001 Certified and is suitable for molding a wide range of materials. Injection molding is a low-waste, low-cost process that is suitable for production runs of any size, and the final product typically requires little to no finishing.

Structural Foam Molding is used to create lightweight molded parts with dimensional stability and strength-to-weight performance. Structural Foam Molding can reduce molding costs and conserve raw materials and works for parts of all sizes but is ideal for large parts, particularly those that require thicker walls.

Over-Molding utilizes heat and pressure, which allows Lomont to mold two materials together. We offer Over Molding services that are utilized for a range of applications including electronic devices, medical devices, automotive components, appliances, and others. Over-Molding is available for various material types.

Injection molding is the ideal technique to manufacture a broad range of exterior car components. Our team of experienced injection molding professionals works closely with automotive OEMs and Tier 1 clients to evaluate and define all technical requirements and therefore optimize the production of impeccable exterior vehicle components. We are plastic injection molding manufacturer of automotive exterior parts e.g.: mudguards (fenders), wheel arches, grilles, sensor holders, floor rails, trunk trims front and rear coverings, bumpers and exterior car door trim, door panels. Our injection plastic parts for cars are found in the a variety of car models worldwide.

Lomont’s Manufacturing Services are focused on delivering quality products and development utilizing the latest technologies in CAD software. We can assist with all stages of product and tooling development and offer services to help you reduce tooling costs and lead times.

Injection molding is the ideal technique to manufacture a broad range of exterior car components. Our team of experienced injection molding professionals works closely with automotive OEMs and Tier 1 clients to evaluate and define all technical requirements and therefore optimize the production of impeccable exterior vehicle components. We are plastic injection molding manufacturer of automotive exterior parts e.g.: mudguards (fenders), wheel arches, grilles, sensor holders, floor rails, trunk trims front and rear coverings, bumpers and exterior car door trim, door panels. Our injection plastic parts for cars are found in the a variety of car models worldwide.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly