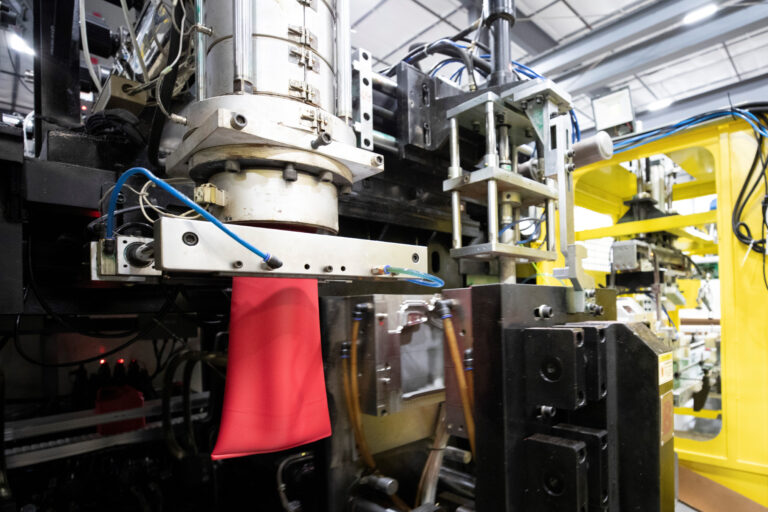

Rosti Group - rosti injection moulding

Author:gly Date: 2024-10-15

Texas Injection Molding provides custom plastic injection molding services for OEM manufacturing and consumer products. Located in Houston but also serving in Austin, San Antonio, and the S. E. United States, Texas Injection Molding provides product design assistance and engineering services for the development of plastic injection molded products. We offer decades of experience in processing commodity and custom engineered plastic resins and partner with the world’s leading resin manufacturers and custom compounders to bring solutions to complex plastic engineering applications. We strive to be known in the markets we serve as the best partner for custom plastic injection molding manufacturing services that operates to the highest ethical standards.

Innovative and Creative – Our employees are the most valuable asset of the company and the only asset that has the ability to innovate and generate creative ideas to provide solutions to customer challenges. We will encourage teamwork, creative thinking, and innovation as a primary avenue to add value to our customers, reduce cost and improve quality.

The addition of glass powder or fibers to nylon resin creates this engineering grade resin. Glass is added to polyamides to increase their mechanical strength, rigidity, and hardness. It also makes them more resistant to creep, wear, chemical exposure, and high temperatures.

Our business strategy and operating plan is built upon People, Process Control, and Technology. We believe that by combining the best talent with proper technology to control the injection molding process we will manufacture consistent high quality parts for our customers. We also believe that culture is a strategic advantage and when we can foster an environment where people care for each other they will take care of the equipment, resin, customers and company.

Texas Injection Molding offers in-house tooling design and engineering support for new injection molds and has both in-house and outside plastic mold building resources to provide cost effective solutions to new tooling. Our in-house tooling group provides routine preventative tooling maintenance and tooling repairs to keep customer production running on-time.

Scientific plastic molding design, material processing, and process control are advancing. Glass filled nylon injection molding can create molded parts that replace metal parts. This is beneficial for applications that require a reduction in weight or noise.

Glass filled nylon injection molding is a practical choice for creating durable molded parts that will encounter friction and wear. The main characteristics and benefits of molding with this material compared to general purpose nylon include:

An Adventure to Live – We will continuously evaluate business opportunities and seek to realize those opportunities that provide great value to the customer, inspire the organization, and provide great satisfaction to the organization when realized.

These qualities make glass-reinforced polyamides superior to general purpose polyamides. The engineered resin has advantageous mechanical properties. It is suitable for injection molded parts that need to endure high static loads over long periods in high temperature environments.

World Class Service – We listen to our customers, anticipate their needs, and seek to exceed their expectations prior to them having to ask.

Plastic Molded Concepts has expertise in molding with many different engineering-grade resins, including glass filled nylon.

Integrity – We will be known in the industries we serve as a company that fulfills our commitments and operates to high ethical standards.

We provide a comprehensive range of plastic molding services including mold design assistance, modeling, prototyping, manufacturing, and testing.

Polyamides are commonly known as nylon. They are one of the most used engineering thermoplastics. Nylon is extensively used for wire coatings and other electrical components. Glass filled nylon is the preferred choice when you need a tougher material, as it makes the nylon considerably stronger.

Plastic Molded Concepts is a U.S based company that uniquely specializes in molding with engineered resins. We have been thriving in the plastic molding business for 45 years. We have the experience and certified in-house Master Molders, allowing us to take on projects of any complexity.

Since the glass filled material is nonconductive, it is ideal for applications within the automotive and electrical industries. It is also a practical choice for manufacturing parts that handle electrical currents.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly