Pvc Mouldings - Mouldings - Building Materials - Wilcon Depot - plastic moulding

Author:gly Date: 2024-10-15

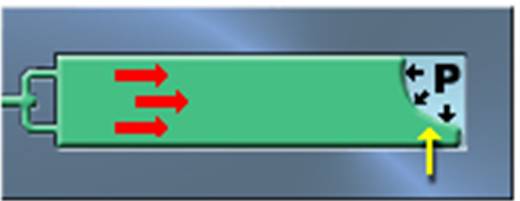

Causes Flow restrictions Due to channels freezing or inadequate runner design. Hesitation and long or complex flow paths Inadequate venting Back pressure due to unvented air traps can cause a short shot. Low melt and/or mold temperatures Insufficient material entering the cavity An undersized machine, low shot volume, or inadequate ram speed. Machine defects Including an empty hopper, blocked feed throat, or a worn non-return (check) valve that causes loss of pressure or volume leakage.

We have been producing both single-shot and multi-shot injection plastic parts for many years. We are proud to say that we have over 95% customer retention rate.

High-precision injection moulding is a process that is crucial in heavy industries, medical devices, consumer electronics and more. This makes sense since some of these parts are literally half an inch in size.

Plastic injection moulding is used in a wide variety of functions and in producing a bewildering array of parts. These include cogs, gears, wheels, casings, and more. In many cases, the demands for precision can go down to microns. A human hair is anything from 30 to 100 microns and a precision part has tolerances of up to +/- 5 microns.

When it comes to injection moulding, there are a lot of points to consider, including the level of precision of the parts specified and the lifespan tools that will be used for the job.

Back pressure due to unvented air traps can cause a short shot. Low melt and/or mold temperatures Insufficient material entering the cavity An undersized machine, low shot volume, or inadequate ram speed. Machine defects Including an empty hopper, blocked feed throat, or a worn non-return (check) valve that causes loss of pressure or volume leakage.

Among the industries that precise plastic injection moulding parts are used include the medical industry where surgical machines require small, intricate parts to function. The auto and airline industries make use of such parts, as well, but so does the tech market.

Many aspects of the plastic injection moulding process are highly controlled. Numerous factors are taken into consideration for polymer selection for certain parts; factors such as durability, strength, costs, secondary processes requirements, etc..

At Kore Industries, we only use the most advanced and cutting-edge technology in plastic injection moulding for producing high-precision parts that our customers need.

This is an application for employment with Kore Industries. This application will be considered current for a period of sixty (60) days following the date of application. If, at the end of this period, you still wish to be considered for employment by Kore Industries. It will be necessary for you to complete another application. Kindly complete the attached Consent Form before the application is considered valid.

Remedies Before you try one of the methods listed below, check all of the other results, so that you know the exact cause of the short shot. Avoid hesitation Eliminate air traps If air traps do exist, they should be positioned in regions that can be easily vented or ejection pins added so that air can be removed. Increase mold & melt temperature This will decrease the viscosity of the melt, making it easier to flow through the part. Increase ram speed This can cause greater shear heating, which can decrease the viscosity of the melt, making it easier to flow through the part. Change part geometry Balance flow paths so they fill in an equal time and an equal pressure. You may need to thicken thin sections, or reduce the complexity of a flow path. Change material Select a less viscous material (higher melt flow rate). By choosing a material with a higher melt flow rate, less injection pressure will be required to fill the part. Increase the maximum injection pressure for this part Solving one problem can often introduce other problems to the injection molding process. Each option hence requires consideration of all relevant aspects of the mold design If you need high quality injection mold tooling, Contact us. If you need high quality plastic extrusion services, Pls contact us sales@viewmold.com If you need high quality sheet metal parts, Pls contact us sales@viewmold.com Injection Molding air trap issue and solution Injection Molding brittleness issue and solution Injection Molding burn issue and solution Injection Molding crack issue and solution Injection Molding delamination issue and solution Injection Molding dimensional variation issue and solution Injection Molding discoloration issue and solution Injection Molding excessive part weight issue and solution Injection Molding fish eye issue and solution Injection Molding flash issue and solution Injection Molding follow line issue and solution Injection Molding hesitation issue and solution Injection Molding high volumetric shrinkage issue and solution Injection Molding jetting issue and solution Injection Molding overpacking issue and solution Injection Molding racetrack effect issue and solution Injection Molding short shot issue and solution Injection Molding sink mark and void issue and solution Injection Molding unbalanced flow issue and solution Injection Molding underflow issue and solution Injection Molding warpage issue and solution Injection Molding weld and meld line issue and solution

Plastic injection moulding is a process in which polymers or resin are melted and then injected through a heated barrel driven by a rotating screw. The pressure and heat generated by the rotating screw in the barrel melts the plastic pellets to be expelled into an injection mould.

To that end, the equipment used for producing such precise parts must be of the highest precision levels. The moulds themselves would need to be as well built within super tight tolerances with ample cooling as well as gas relief for instance to achieve such precision requirements.

For any technical consultation or to get a quick quote, please contact us by filling up the form below. We’ll get back to you as soon as we can.

Injection Molding defect:molding short shot All Injection molding defects>Solving molding short shot problems Definition A short shot is the incomplete filling of a mold cavity which results in the production of an incomplete part. If a part short shots, the plastic does not fill the cavity. The flow freezes off before all of the flow paths have filled. To ensure the finished part is of good quality, the part must also be adequately packed with plastic. Therefore the question to ask is not only, 'Will the part fill?', but, 'Can a good quality part be made?' Causes Flow restrictions Due to channels freezing or inadequate runner design. Hesitation and long or complex flow paths Inadequate venting Back pressure due to unvented air traps can cause a short shot. Low melt and/or mold temperatures Insufficient material entering the cavity An undersized machine, low shot volume, or inadequate ram speed. Machine defects Including an empty hopper, blocked feed throat, or a worn non-return (check) valve that causes loss of pressure or volume leakage. Remedies Before you try one of the methods listed below, check all of the other results, so that you know the exact cause of the short shot. Avoid hesitation Eliminate air traps If air traps do exist, they should be positioned in regions that can be easily vented or ejection pins added so that air can be removed. Increase mold & melt temperature This will decrease the viscosity of the melt, making it easier to flow through the part. Increase ram speed This can cause greater shear heating, which can decrease the viscosity of the melt, making it easier to flow through the part. Change part geometry Balance flow paths so they fill in an equal time and an equal pressure. You may need to thicken thin sections, or reduce the complexity of a flow path. Change material Select a less viscous material (higher melt flow rate). By choosing a material with a higher melt flow rate, less injection pressure will be required to fill the part. Increase the maximum injection pressure for this part Solving one problem can often introduce other problems to the injection molding process. Each option hence requires consideration of all relevant aspects of the mold design If you need high quality injection mold tooling, Contact us. If you need high quality plastic extrusion services, Pls contact us sales@viewmold.com If you need high quality sheet metal parts, Pls contact us sales@viewmold.com Injection Molding air trap issue and solution Injection Molding brittleness issue and solution Injection Molding burn issue and solution Injection Molding crack issue and solution Injection Molding delamination issue and solution Injection Molding dimensional variation issue and solution Injection Molding discoloration issue and solution Injection Molding excessive part weight issue and solution Injection Molding fish eye issue and solution Injection Molding flash issue and solution Injection Molding follow line issue and solution Injection Molding hesitation issue and solution Injection Molding high volumetric shrinkage issue and solution Injection Molding jetting issue and solution Injection Molding overpacking issue and solution Injection Molding racetrack effect issue and solution Injection Molding short shot issue and solution Injection Molding sink mark and void issue and solution Injection Molding unbalanced flow issue and solution Injection Molding underflow issue and solution Injection Molding warpage issue and solution Injection Molding weld and meld line issue and solution

Highly sensitive and precise machines must get their parts from correspondingly precise injection moulding products. To that end, let’s take a look at some of the points of concern regarding precision plastic injection moulding.

These parts are then inspected and tested for quality. Parts that passed the quality control are sent for packaging or are immediately placed inside the machines or devices that they were meant for.

2K injection mould and moulding is considered a precision tooling and moulding process based on the tight machining tolerances required.

Definition A short shot is the incomplete filling of a mold cavity which results in the production of an incomplete part. If a part short shots, the plastic does not fill the cavity. The flow freezes off before all of the flow paths have filled. To ensure the finished part is of good quality, the part must also be adequately packed with plastic. Therefore the question to ask is not only, 'Will the part fill?', but, 'Can a good quality part be made?'

Smartphones, computers, cameras, and many others require specialized moulded precision parts in order to function properly. A case in point is waterproofing of plastic housings; these are best done with the 2K moulding process which is made up of hard plastics housing with a soft seal.

Precision injection moulding has to be approached in an engineering-driven and methodical approach. This is especially relevant if you consider the consistency and the quality of your products. It may not be obvious at the beginning of the program but the consistency and quality of the injection moulding process directly affects the profitability of the program. This can be doubly true when you are working on programs for use in the automobile or medical industries which could last for years if not decades.

We take pride in being the most professional plastic parts manufacturer for every industry. We can create any kind of plastic gear that our customers want at the highest possible quality they could ask for.

As more manufacturers adopt fully automated assembly lines where moulded parts and other relevant components are fed into the final assembled products come out, the dimensional precision and repeatability requirements increase. This is why you need injection moulding products that are specialized in producing highly precise and uniform parts.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly