Prototype Injection Molding: When and Why To Use It - prototype plastic molding

Author:gly Date: 2024-10-15

Forum is always looking for the next technology to support our customers’ needs and to expand our capabilities. With FIM, we saw the potential to place parts in customers’ hands very quickly and to support customers from design through the prototype/low-volume phase.

For over 30 years, Forum Plastics has focused on being the development partner of choice for OEM partners. Our mantra has always been from prototype to production, and because of that focus, we have offered solutions including 3D printing/additive manufacturing as well as steel-based quick turn tooling. To further expand our rapid prototyping services, we made a recent investment in freeform injection molding to supplement our already robust rapid prototyping capabilities. The addition of FIM truly reinforces the idea of getting there faster with Forum.

FIM is a powerful tool in the hands of micro injection molders wanting to fast track product development and low-volume production. The inevitable question for medical device partners is FDA compliance. Multiple bioburden lab tests were conducted using various injection molding material grades, and the results were favorable. Tests results are available from Forum upon request.

The Toolmaker is optimized for manufacturing of 3D-printed tooling. With precision- and repeatability, it delivers printed tools with detailed features as small as 10µm. It enables economic manufacturing of prototypes and small-scale production – in the entire range of injection moldable materials.

Freeform injection molding offers access to everything including legacy, medical-grade, and FDA-approved materials. In other words: all materials approved for injection molding are compatible with FIM.

Utilizing our suite of capabilities and value-added services, our industry-focused commercial and technical teams are available to provide support, optimization recommendations, and partnership-focused business strategies to meet or exceed your program initiatives. From 3D printing of conceptual models and mold cavities to final assembly, packaging, and customized release test development, Forum is ready to support your device program needs.

Material choice is one of the most critical decisions faced during development. Freeform injection molding is the ideal prototyping platform because it supports the full range of injection molding feedstock, treats the materials the same way, and achieves the same isotropic material properties as conventional injection molding for accurate manufacturing grade testing.

The Toolmaker is optimized for manufacturing of 3D-printed tooling. With precision- and repeatability, it delivers printed tools with detailed features as small as 10µm. It enables economic manufacturing of prototypes and small-scale production – in the entire range of injection moldable materials.

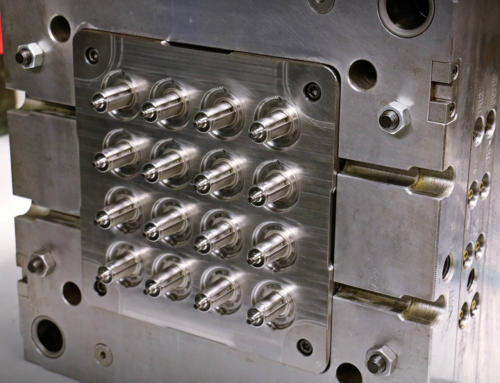

Freeform injection molding (FIM) uses 3D printing technology to make molds and cavity blocks compatible with injection molding. This technology allows parts to be made from the design intent material. Our customers are not limited to a select few materials since all grades are possible. Utilizing the unique abilities of 3D printing, mold cavities can be made that otherwise would either not be possible to create or would have significantly higher lead times and costs.

FIM is the perfect method for prototyping lower quantities as it is quick and cost effective compared to conventional steel tooling. This technology is geared toward low-volume, custom specialized components. However, for higher quantities, a customer may also decide to use FIM due to its ability to use the specified resin, ease of manufacturability, short lead times, and convenient modification process if design changes are needed. Freeform injection molding speeds up tool iterations with unseen details and tight tolerances. Whether you are a designer, engineer, or toolmaker, FIM is a gateway to optimum design freedom that maintains the strengths of injection molding.

The significant difference between FIM and regular injection molding is the advantage of being able to 3D print your cavity design. With this technology, a cavity can be designed, printed, and molded in 1-2 weeks, whereas machining a cavity out of steel would take many weeks and require the expertise of a tool maker.

A prototype in a different material made by a different process is simply look-a-like, and therefore it will not perform like the final product. Freeform injection molding is not look-a-like. It produces components at manufacturing grade with the exact material properties of the production part ready for test and qualification. If part validation (IQ/OQ/PQ) is required, Forum will work with customers to develop testing protocols. Forum has the capability for performing part inspection in house using validated test methods.

We welcome the most challenging engineering requests. Start a partnership with Forum today by requesting a quote for your next project.

XTONG chemical employs veteran chemical engineers who are capable of conducting product evaluations and performance demonstrations both in the laboratory and in actual plant processes. Our team has extensive experience in identifying the right solutions for a variety of applications and is well-suited for any project at hand. We know that every project comes with its own set of unique challenges and we're eager to help develop a solution that meets your needs.With over 15 years experience sourcing and distributing chemicals for various industries, coupled with vast experience in direct and online sales XTONG Chemical was formed to provide high quality products with a super fast delivery turn around-covering industrial chemicals,Agricultural chemicals plastics and resin.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly