Precious Injection Plastic - precious plastics injection molder

Author:gly Date: 2024-10-15

Permit the first injection-molded part’s edge to be excessively large. This assures that the second injection will have a higher pressure.

Because the mold’s core and cavity do not need to be relocated, the core toggle multi shot molding procedure is the simplest. Alternatively, shifting the slider will alter the geometry of the mold cavity.

The remaining space is filled by moving the slider after material B is injected into the modified cavity through a different gate (above the middle nozzle).

Bespoke Solutions: Custom molding allows for the development of parts engineered for specific uses or environments, ensuring optimal performance. Material Selection: Manufacturers can choose from a myriad of plastics and composites tailored to the application, enhancing product performance. Increased Competitive Edge: Customized solutions can differentiate products in the marketplace, giving businesses an edge over competitors.

A part made of hard material can be joined to a part made of soft material using two shot injection molding. In a two cavity mold, the procedure combines the molding of two components. It can significantly improve the product’s appeal in terms of feel, color, etc. There are many different design possibilities with two-shot molding.

In these situations, the mold’s two halves seal against one another. Due to this, the sealing faces of the mold can open and close without colliding with one another. Three to five degrees should be the minimum draft angle. The longer the mold lives, the higher the clearing and the greater the draft.

The latter often uses two different molds, one for each material, but can also be carried out using just one mold, two runner systems, and manual or automated pick-and-place part transfer.

The lifespan of a mold can affect the overall production costs. Companies that prioritize high-quality materials and craftsmanship in their molds can provide more durable options, reducing downtime and costs over time.

The melted resin enters the mold chamber through a gate channel when using injection molding. To achieve the ideal part proportions and aesthetic look while preventing warping, the type of gate, design, and location must be taken into account.

Two-shot molding can be done using rotary platen, movable core, or overmold, among other options. The first two require two processes, two runner systems, and a second injection unit.

This is essential for producing solid surface cosmetics and a homogeneous mold. In single-shot injection molding, the melt can enter through the thickest part of the opening before flowing to the smaller areas, thanks to the gate’s placement.

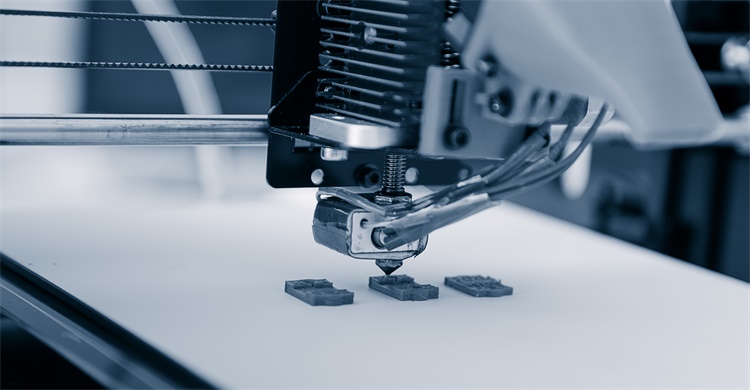

Melting: Plastic pellets are fed into a heated barrel where they melt and form a viscous material. Injection: The melted plastic is injected into a closed mold at high pressure. Cooling: The molten plastic cools and solidifies, taking the form of the mold. Ejection: Once cooled, the mold opens, and the finished part is ejected.

In order to create the first segment of the product, one material is first injected into a mold. A second injection of a secondary material compatible with the first follows this. There are several reasons why many businesses choose to produce plastics or polymers this way.

In two shot injection molding, a first section is molded, and after it is complete, a second part is injected to create the molding’s final portion. Both pieces must be comparable (chemically) for the two shot molding process to be successful for bonding to take place.

An injection molding machine is used in the two shot molding process where two materials are “over molded” in one molding cycle. The amount of material injected into the molding cavity is referred to as a “shot.”

Although the procedure is simple to grasp, mastering it is challenging. Even the tiniest errors can result in significant financial losses because of the high levels of technical competence and attention to detail required, especially in high-volume manufacturing circumstances.

Plastic injection molding is a cornerstone of modern manufacturing, playing a pivotal role in producing everything from household items to intricate components for the automotive and aerospace industries. As businesses seek efficient and cost-effective production methods, understanding the nuances of plastic injection molding services is more crucial than ever. This article will delve into what plastic injection molding is, the key players in the industry, and the importance of choosing the right injection molding companies for your needs.

Custom injection molding services are vital when standard solutions do not meet specific project requirements. These services enable businesses to create unique parts tailored to their applications.

Two shot molded parts are utilized in almost every industry, from consumer goods to construction, but they are most frequently used in situations needing the following:

If you have any need for plastic injection tooling and molding, you are most welcome to contact us via Joyce Wang, info@gbmmould.com;

The plastic component is then forced out of the mold after hardening. Circulated in the same order as above to continue the molding.

With two shot molding, several components can be molded with a single tool, requiring less work to produce your parts and no post-molding welding or joining of the components.

Physical, mechanical, chemical, thermal, electrical, flammability, and UV resistance are all important considerations when selecting a material for your component. You’ll need to provide answers to a number of questions in order to focus your material selection, including:

The soft plastic is molded a second time after being first molded as hard plastic. The first time is transparent; the second time isn’t. The first molding is done with a high temperature plastic, while the double molding is done with a low-temperature plastic.

For intricate, multiple colors, and multi-material plastic goods, especially in high-volume manufacturing circumstances, two shot injection molding is the best plastic molding technique.

A cutting-edge manufacturing technique called double injection, also known as two-material, two-shot molding, or two-K molding, is used to create intricate molded parts from two different materials.

Strong communication is vital throughout your project. Consider working with injection molding companies that demonstrate excellent customer service and are willing to guide you through every phase of the production process.

Although the tool’s price increases when a slider is added to the mold, it can still be significantly less expensive than rotating platen or rotary shaft molds. Sadly, it is unable to make intricate, multicolored plastic pieces.

The structure contains closed numeric or alphabetic characters like 0, 4, 8, A, B, D, and O. The secondary material can only easily enter the confined region when a seesaw construction is used, creating a lovely appearance.

The male model cavity glides under the influence of the motor as the mold is opened after one injection. A specified distance is used to align the mold with the master mold before the second injection molding process.

Quality should be a top priority. A reliable plastic injection molding service provider will adhere to strict quality control processes, conducting thorough inspections to ensure every part meets standards.

For a strong molecular bond to be possible, your substrate and second-shot resin should ideally be chemically compatible. The longest leg or surface area is ideal for the joint between the two resins. The second shot is nearly impossible to remove by selecting the ideal materials and joint design.

Injection molding parts are used across numerous sectors, underscoring the versatility of this manufacturing technique. Here’s a brief look at some of these industries:

In electronics, the assembly of complex circuitry requires precision components that can be seamlessly integrated with other parts. Injection molding provides the reliability and consistency needed for these applications.

When seeking plastic injection molding services, it's crucial to work with reputable injection molding companies. Here’s what to consider when evaluating potential partners:

Product makers prefer two shot injection molding for a variety of applications, including automotive interior parts, medical equipment, tools, and toys. It enables manufacturers to mix a multitude of components and hues to produce a robust and aesthetically pleasing product.

Look for companies with extensive experience in custom injection molding. Expertise in your specific industry can be a significant advantage and ensure that the parts produced meet your stringent specifications.

The two shot injection molding technique is divided into two steps. The first involves an injection of resin into a mold, which is then cooled to create a solid object, much like traditional injection molding.

During the two shot injection molding, we carefully control the injection of numerous materials, including two distinct types of resin, into a single, multi-chambered mold using a highly specialized and automated technique.

The method is also excellent for making soft handles for electrical equipment, air conditioning seals and gaskets, and non-slip surfaces. With this method, logos may be created that, unlike painted-on logos, would never fade.

From toys to kitchen utensils, plastic injection molding allows for mass production of consumer goods that are both cost-effective and tailored to consumer preferences.

Take into account the two materials’ shrinking. Generally speaking, the material that is initially created affects shrinkage.

Following the formation of a molecular link between the two plastic resins, the multi-resin molded object is cooled and expelled.

The medical industry demands high standards in terms of design and compliance. Plastic injection molding can produce critical components such as syringes, surgical instruments, and medical housing that meet stringent regulatory requirements.

In addition, the two shot molding process is applied in the automotive sector to make a wide range of products and parts. Other items made using the double shot process include lawn and garden tools and agricultural equipment.

A material compatibility table is reviewed to determine which polymers will cling to one another and which polymers are incompatible. Additionally, it eliminates the possibility of contamination, which is an issue when utilizing two different molds.

Efficiency: High-speed production allows for thousands of identical parts to be produced in a single day. Complex Shapes: Advanced mold designs enable intricate and complex geometries that are challenging to achieve through other manufacturing processes. Material Versatility: A wide range of thermoplastic materials can be used, making it suitable for various industries. Cost-Effectiveness: While initial mold-making can be expensive, the per-unit cost decreases significantly as production volume increases, making it economical for large runs.

The chemistry of the materials is crucial to take into account when deciding which ones to utilize for two-shot molding. While some materials bind imperfectly, others work well together and create a solid molecular adhesion.

Two different plastic resins are molded together in a single machining cycle during the double injection molding process, also known as dual shot, double shot, multi shot, and overmolding.

Plastic polymers are utilized in a range of production processes, such as extrusion, compression thermoset molding, and two shot injection molding. While each is a feasible manufacturing method, many plastics manufacturers use this method due to several advantages.

The method produces more products each run for less money and requires fewer workers to produce the completed product since it uses a single machine cycle rather than multiple machine cycles. Additionally, it guarantees a solid binding between the materials, eliminating the need for later assembly.

Plastic injection mold companies play a critical role in the process, designing and manufacturing the molds used in injection molding. The quality and design of these molds directly impact the finished product. Key factors to consider include:

Modern injection molding requires advanced machinery and technology. Companies equipped with state-of-the-art machines and capabilities for complex part designs ensure better accuracy and efficiency in production.

In automotive applications, precision and durability are pivotal. Injection molded parts can be found in dashboard components, bumpers, and numerous internal parts, ensuring that they withstand harsh conditions and provide longevity.

In addition, compared to producing an identical product or part using two different molding processes, the two shot molding procedure results in a much stronger bond. The ability to make multicolored plastic goods using the two-shot molding method is one of the process’ additional advantages over painting, which may lose its effectiveness over time.

You may create more useful, sophisticated elements using the two shot approach. Further, softer plastic may be mixed with hard plastic. The product has significantly greater integrity. Two-shot plastic molding products are often far more durable and shockproof.

This is why choosing a supplier with exceptional skills is important. Excellent supplier quality scorecards established processes to prevent flash, flow lines, short-shots, and backup plans from increasing capacity as your company and your needs for two shot molding expansion are all things to look for.

Plastic injection molding service is an invaluable asset in modern manufacturing. Whether you are a startup looking to develop a new product or an established company seeking to improve manufacturing efficiencies, understanding the landscape of plastic injection molding, including the significance of injection molding companies and plastic injection mold manufacturers, is essential. Selecting the right partners is crucial to achieving your production goals, ensuring quality, and maintaining your competitive edge.

Choosing and ending up with the proper mold structure is essential to save on costs and ascertain quality. Here are some types of two shot molding structures:

Many plastic injection mold companies offer rapid prototyping services, which allow clients to test designs before committing to large-scale production. This can save time and reduce the risk of costly mistakes.

With the first mold rotated out of the way and the second mold placed around the product so that the second compatible thermoplastic can be injected into the second mold, the two-step procedure only requires one machine cycle.

The mold, which can hold more materials, is only seen here with the two materials. Depending on how much material is utilized, the rotating platen can be rotated by 90°, 120°, or 180°. A specific injection machine is also required to produce the necessary rotation on the core side.

Different projects require different types of plastic. A reputable supplier will offer a variety of materials to meet your needs, whether you're producing automotive parts or consumer goods.

The newly-molded object is transported to a second mold in the second stage using a rotating platen or a robotic arm. Depending on the design, the newly-molded part is then given a second injection of resin in, through, or around specific areas of the first mold.

The number of parts in a finished assembly is decreased using two shot injection molding, saving an average of USD$40K in development, engineering, and validation expenditures for each increased part number.

Conduct an adhesion test before beginning manufacturing when the adhesive property of two compounds is unclear. When bonding is insufficient, fixes can be incorporated into the design, such as undercuts, grooves, or shoulders, to increase adhesion and lock the two compounds together.

Materials like silicone and thermoplastics, nylon and thermoplastic elastomers, or stiff nylon and soft touch materials are a few examples of materials that can be blended successfully with this procedure.

Even when a high-level chemical bond may be achieved, we highly advise using an appropriate mechanical bond if bonding is important to your application.

On the centerline of the platen, which parallels the axis of rotation, the mold core plate has two identical cores that are mirror images of one another. Two cavities with various geometries are included in the cavity plate attached to the fixed platen.

By working with reputable plastic injection molding service providers and leveraging custom injection molding capabilities, businesses can bring innovative and reliable products to market efficiently. If you’re considering leveraging plastic injection molding for your next project, take the time to research and choose the best injection molding companies and mold manufacturers that align with your needs. By doing so, you’ll position your business for success in an ever-evolving marketplace.

With one side moving up, the other side moving down, and so on, the slab structure is made up of two sides rotating around the center. Most keyboard mold designs with numbers and letters use the seesaw structure.

Substance A is first injected into the cavity when the slider is in its expanded position during the injection molding process using the core toggle two shot mold. Then pulling the slider back to expose a new area of the cavity.

A broken hole is created as the needle rises at the edge of the sealed-off portion of the primary product. To drill the secondary material into the closed area from the broken hole, the needle is moved lower by the returning pin of the fractured plate during the double injection molding process.

People who are unfamiliar with two-shot injection molding might think it’s difficult. It does involve a second material and procedure, which adds another factor to component creation, but it’s relatively easy.

To form holes, snap features, and lengthy through-holes, the mold closes these places to prevent plastic flow into those locations.

A skilled mold manufacturer should be able to offer innovative mold design services, ensuring that the mold facilitates efficient and accurate production. This includes considerations for cooling channels, ejection mechanisms, and design for manufacturability (DFM).

Plastic injection molding is a manufacturing process wherein molten plastic is injected into a pre-designed mold to create a specific shape or part. This technique allows for the rapid production of plastic parts in large quantities, making it highly sought after in various industries. The process generally involves the following steps:

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly