PPC Moulding Services - plastic injection service

Author:gly Date: 2024-10-15

Thermoplastic over thermoplastic. Using two different thermoplastic materials, such as a rigid plastic material like PC and a softer rubber-like material like TPU for improved grip or comfort.

What are the most common defects in the injection molding process and how do you avoid them? This article provides six essential design tips for avoid production defects while reducing the cost and lead time of your molded parts.

Silicone over plastic. Adding a silicone layer to a plastic material such as PC for water resistance, sealing, and enhanced tactile properties.

Acrylics can be mixed with resins to create a wide variety of colored products. It can be further modified to improve a specific property. This is generally achieved by incorporating additives. These modifications are typically performed

PMMA beads or pellets which are usually the starting material should be free of solvents to avoid the formation of bubbles. This is achieved by drying. PMMA Injection molding is the same process as conventional injection molding:

In addition to prosthodontic applications, PMMA can be applied to a wide range of medical applications such as diagnostics, and incubators.

Enhanced functionality. Overmolding allows the integration of different materials with distinct properties, resulting in improved grip, cushioning, insulation, or sealing, enhancing the overall functionality of the product.

Acrylics are more flexible, lighter in weight, and exhibit more impact resistance than glass. They are easier to mold and fabricate according to the design specification. Additionally, Acrylics exhibit better insulation properties than glass which makes them perfect for skylights.

Want to learn more about exactly how an injection molding machine functions, as well as its individual parts? This article puts injection molding machines under the microscope, with detailed descriptions of their components and an in-depth guide to the injection molding process.

Acrylics are not only cost-effective but also more durable than glass. It demonstrates more impact resistance than glass (Usually 10X more). Additionally, Acrylics offer a lustrous shine and a glossy finish!

Since PMMA is lightweight and resistant to salt and cleaning products, it is extensively used for manufacturing windshields and windows. PMMA is also used for windscreens, windows, and canopies in airplanes as it can resist high inside cabin pressure and harsh UV radiations.

Medical equipment. Overmolding is employed in medical device housings, enhancing durability and ergonomic design for instruments like handheld scanners and diagnostic tools.

Venting. Integrate venting features in the design to allow air and gases to escape during injection, preventing voids and trapped air pockets.

Packaging. Overmolding contributes to the creation of ergonomic and comfortable grips on packaging machinery handles, improving operator experience and efficiency.

When producing parts with injection molding, understanding the range of materials that are available is crucial. Find out more about those materials, their properties, and factors to consider when choosing a material for injection molded parts.

Further developments and advanced technology developed a far more accessible and cost-effective PMMA that could be used for consumer applications. This particular development made PMMA a versatile plastic whose application spreads today, across several industries!

Overmolding offers versatile solutions to manufacturing challenges by combining different materials to enhance product functionality, durability, ergonomics, and aesthetics. The following are several of the advantages of overmolding.Â

PMMA is commonly known as acrylics. Some of its common trade names are Crylux, Plexiglas, Acrylite, Lucite, Perclax, and Perspex. PMMA sheets that are of the glass type are called Plexiglass. It is also used in high-end applications such as hip replacement and lenses for eyewear.

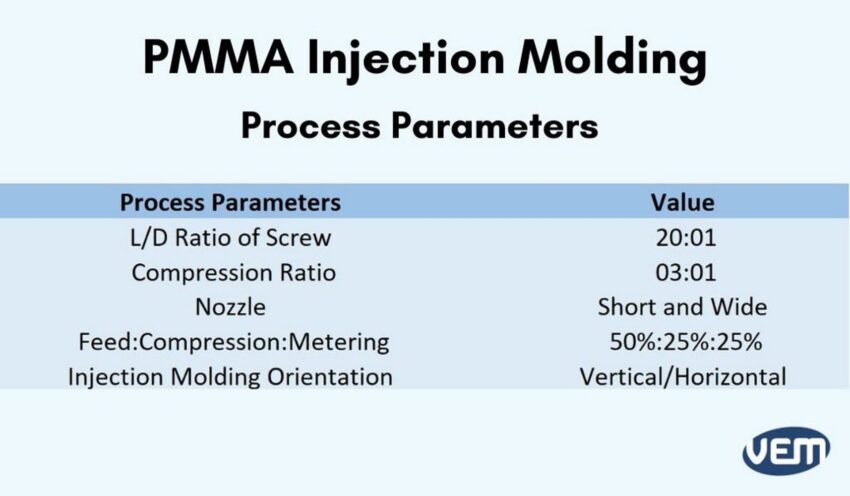

The thermal stability of PMMA injection molding is medium and the thermal decomposition temperature is slightly higher than 270℃ / 518°F. For screw-type injection molding machines, the barrel temperature should be controlled at 180 – 230℃/ 356 – 446°F.

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

Ergonomic design. Overmolding enables the creation of ergonomic shapes and contours, enhancing user comfort and interaction, making products more user-friendly and intuitive to use.

Standardization and quality are part of our companies core values. We deliver the best possible experience and product to our customers, every single time consistent. Take a look at our certificates!

Acrylics have a water absorption rate of 0.3-0.4%. For injection molding, it should be below 0.1% of the temperature i.e. usually 0.04%. The presence of water leads to air bubbles and the formation of airlines thus, PMMA resins need to be dried well before introducing them into the barrel.

PMMA has unique properties such as low density, biocompatibility, UV resistance, easy molding, and delivering aesthetics while being cost-effective. PMMA has thus become a popular biomaterial for dental applications. It is commonly used for prosthetic dental applications such as the fabrication of artificial teeth, denture bases, dentures, orthodontic retainers, and crowns, and the repair of dental prostheses.

As injection molding developed and became more integral to manufacturing, PMMA became even more versatile and the ‘plastic of choice’ for various manufacturers! Today PMMA gets injection molded into countless products.

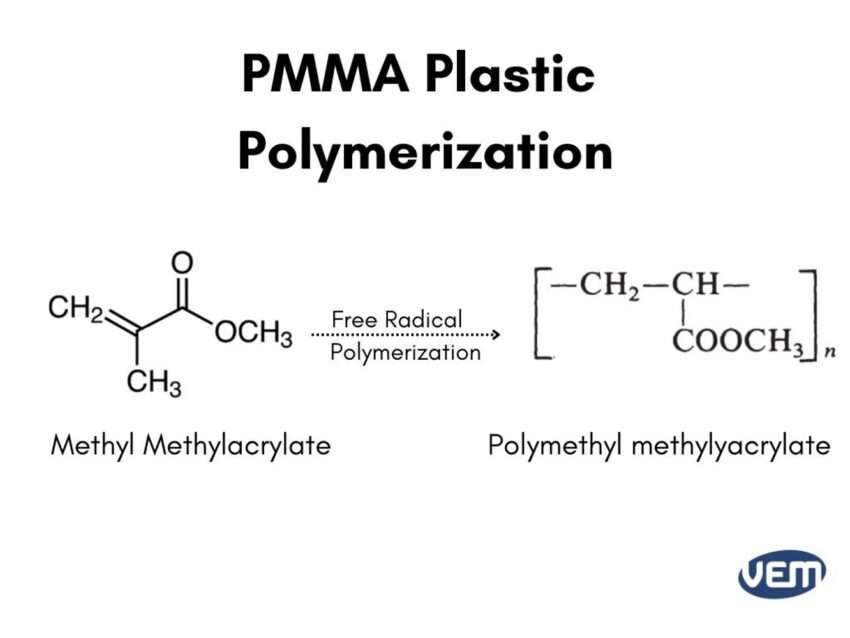

PMMA, abbreviated for Polymethyl methacrylate, is a transparent and rigid thermoplastic. PMMA is a polymer that is produced through the polymerization of monomer methyl methacrylate.

Draft angles. Incorporate draft angles to aid in easy part ejection from the mold, reducing the risk of damage during demolding.

Level up your injection molding knowledge and find practical tips about selecting materials, working with draft angles, and reducing costs.

What are the common applications of injection molding? What sets it apart as a manufacturing process? This article covers the key benefits of injection molding and provides insight into whether injection molding is right for your industryâs applications.

Thermoplastic over elastomer. Combining a rigid plastic such as ABS with a flexible elastomer for products requiring both durability and flexibility, like tool handles or medical devices.

Quality control. Ensuring consistent bonding between different materials can be challenging, and defects like delamination or inconsistent adhesion may arise, requiring meticulous quality control measures.

The cooling rate of acrylics is fast thus, the plastic parts are easily stressed. The high and low control of injection mold temperature should be strictly maintained to avoid this. The general injection mold temperature should be controlled at 40-80℃ / 104 – 176°F.

Ensuring proper material bonding, design intricacies, and quality control are challenges in achieving consistent overmolding results.

Want to learn more about die casting? In this article, weâll take a look at the process, its history and current uses, advantages, design guidelines, and more.

Extruded Acrylics are produced through the extrusion method. Extruded acrylics are produced by pushing acrylic mass through a form thus, depending upon the direction of the flow, they have varying properties. Due to the production process, they are heterogeneous. Some of its properties are listed below:

Design for bonding. Create proper surface features, undercuts, and interlocking structures to facilitate mechanical bonding between the injection-molded part and the overmolded material.

Acrylics demonstrate excellent scratch resistance. In addition, they can be processed toward featuring a glossy lustrous finish. These properties, combined with PMMA’s dimensional stability, enable its use in many different applications, such as automotive body parts, furniture, or kitchen. Additionally, acrylics are more scratch-resistant than any other glass product. In this manner, the molding process generates products that can maintain their lustrous appearances for a long time without degradation.

Durability and protection. Overmolding can add a protective layer, such as a rubber coating, to shield delicate components from impact, moisture, or environmental factors, extending product lifespan.

Process complexity. Overmolding involves multiple steps and material transitions, increasing the complexity of the manufacturing process and potentially leading to quality control challenges.

PMMA has unique properties for the construction industry such as optical clarity and UV resistance. It is an ideal material for construction applications such as sound barriers, facades, aquaria, and greenhouses. PMMA also has high mechanical resistance and its reliability enables architects to build beautiful architectural monuments.

Thermoplastic over metal. Coating metal parts with a protective or cushioning plastic layer, such as encasing steel components with PP, to enhance corrosion resistance and reduce noise or vibration.

Photovoltaic modules of solar panels are continually exposed to harsh environmental extremes such as sunrays and rain. Thus, the solar panels undergo constant stress which is why acrylics are a popular choice for photovoltaic solar modules. PMMA is durable, can withstand stress, and is weather-resistant which is why it is the perfect economical choice for solar applications.

Electronics. Overmolding ensures durability and strain relief for cable connectors, safeguarding cable connections in challenging environmental conditions.

Acrylics are weather resistant which means they are durable and can withstand storms, winds, and heavy rains. There is no degradation in transparency which is why the clarity also remains the same, unlike glass.

Despite its advantages, overmolding presents challenges in terms of design complexity, material compatibility, production costs, quality control, and specialized tooling requirements. Learn more about the challenges in order to overcome them.Â

PMMA is considered to be a better alternative to Glass. Glass is generally expensive, heavy, and can be unwieldy. E.g. iPhone screens are usually Gorilla glass and they are thus, heavy-weighted and expensive whereas various other brands use acrylic plastic for the screen displays thus, making the phones lightweight and relatively cheaper.

PMMA was processed extensively to be further developed such that it can be molded into complex shapes that are required for the biological environment. The earliest application of PMMA was in dentistry and it was later extended to orthopedics for thigh and hip replacements. Since PMMA was lightweight, easily processed, and demonstrates low toxicity, it found various applications in the medical industry. It was, however, not cost-effective and thus, restricted for a while to the medical industry.

Since the viscosity of PMMA melt is high and the flowability is poor, the injection pressure should be maintained high at 80-120 MPa / 11603-17404 Psi. The holding pressure is 40-60MPa / 5801-8702 Psi.

Overmolding improves grip, durability, aesthetics, and reduces assembly steps, creating versatile and comfortable products.

Acrylics are not toxic in their final forms but during production, their manufacturing process releases minute amounts of toxic fumes. Comparatively, the production of toxic fumes is not the same as other materials. Acrylic is classed as non-hazardous under OSHA regulations as it is one of the few materials that has very low toxic fumes released during its production and the final form is free of toxicity.

Acrylics typically allow 92% light transmission which is greater than glass or any other plastic. This light transmission property enables the acrylics to exhibit outstanding clarity. PMMA can thus, be applied in various optical-related applications.

Various combinations include thermoplastics, elastomers, metals, and silicone, chosen for desired properties like grip, flexibility, or sealing.

Want to learn how to design undercuts that donât cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more. Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, weâll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.

Find out about the manufacturing technique used to injection mold a second material over or around a part to create a new one.

PMMA can be molded into developing complex designs. PMMA injection molding process can reproduce a significant number of complex products that are identical in terms of shape, size, and weight.

Avoid sharp corners. Rounded edges and corners help prevent stress concentration and facilitate material flow during the overmolding process.

Acrylics can be modified according to the requirements. They are available in clear as well as various tints and colors. Acrylics can also be texturized to produce a variety of finishes. In addition, Acrylics are also incorporated with additives to exhibit a particular characteristic such as scratch- resistance or glare reduction.

Limited material options. Material compatibility is crucial in overmolding, limiting the selection of suitable combinations â and potentially restricting the ability to achieve specific material properties.

In injection molding, âovermoldingâ refers to a process where multiple materials are used to create a cohesive, often multi-textured product with improved qualities and versatility. Hereâs a guide to using the technique, including how it works, its common industrial uses, and more.

While tooling costs can be higher, overmolding often reduces assembly and enhances product lifespan, justifying the investment.

Overmolded material placement. Position the overmolded material's injection points away from critical features and edges to avoid material entrapment or disruption.

PMMA was first discovered by a German chemist named Otto Rohm in 1901. The PMMA discovered in 1901 was in its most novice and preliminary form and it could not be used for commercial purposes as we use it today. It thus later underwent various developments and by 1943, a more processible form of the PMMA version was developed which created a version of PMMA that can be cured at room temperature.

Costly tooling and equipment. The need for specialized molds and injection molding equipment tailored to overmolding can lead to higher initial investment and tooling costs compared to traditional molding processes.

PMMA demonstrates excellent physical properties such as extensive tensile strength, great flexural strength, and transparency, like glass. One of the most prominent properties of PMMA is that it resembles glass and it is thus often used as a replacement for glass. Additionally, it is a tough plastic material and is an excellent cost-effective alternative to the less resilient glass material.

To get a quote for your overmolding project, start by uploading a part. You can also contact our injection molding experts with any questions or special requirements.Â

Robotics. Overmolded grippers provide robotic systems with a balance of flexibility and rigidity, enabling secure handling of diverse objects.

Why is it important to design draft angles for injection molding custom parts? This article covers why draft angles are essential and how to design them better to get the most out of your injection molding designs.

Overmolding is a manufacturing process that is often used in injection molding, in which a part is encased or covered with a second material â typically a rubber or plastic â to create a single, integrated product. It enhances product durability, grip, aesthetics, and functionality.

PMMA grades are known for their transparency! It allows 92% of the light to pass through, which is more than glass or any other plastic. This outstanding clarity makes it an ideal plastic of choice for various applications in the automotive, aviation, and marine industry such as rear lights, windshields, and plane windows.

Construction. Safety equipment such as hard hats and tool handles benefit from overmolding, providing impact resistance and improved grip for construction workers.

PMMA abbreviated for Polymethyl methacrylate is commonly referred to as acrylics. PMMA injection molding is a process where molten acrylic is injected into a cavity which upon cooling and hardening forms various types of plastic products. PMMA is applied to manufacture various plastic parts such as car windows, aquariums, and mobile phone screens. In this article, we have focused on PMMA injection molding in-depth to help you understand if it’s the best-suited material for your project.

Acrylic has a density of 1.185 g/m3 – 0.00185kg/m3 whereas glass has a density of 2.4 g/m3 – 0.0024kg/m3 thus, PMMA plastic molding produces lightweight products and is an excellent alternative to glass.

Acrylics do not turn yellow in the sun. Acrylics are also not affected by UV rays. They are thus ideal for shed windows and colored skylights. They are also popularly used for panels in home projects.

Applying the following best practices can help ensure successful overmolding, leading to high-quality products with optimal functionality and aesthetics.

PMMA exhibits excellent optical clarity, high light transmittance property, surface hardness, and scratch resistance which are important properties for electronics that would be used on a regular basis. Due to these properties, acrylics are widely applied to manufacture LCD screens, TV, and mobile phones.

Overmolding works by first placing the injection-molded part into a mold. Next, a second material is injected over or around the part. The two materials are then bonded together during the curing process.

The manufacturing process of acrylic products can release highly toxic fumes thus, it needs to be handled with precaution. Anyone who is handling acrylic sheets should be provided with appropriate protective equipment and clothing. If not handled properly and the right precautions aren’t taken, acrylics could blow up during polymerization.

In overmolding, a variety of materials can be used to achieve specific properties and functions. Several common combinations include:

Acrylics are inherently stable to UV light which is why PMMA is used for many outdoor applications such as solar panels.

Reduced assembly. Overmolding combines multiple components into a single piece, reducing the need for complex assembly processes, lowering labor costs, and minimizing the risk of assembly errors.

In addition, PMMA has also been considered a safer option than polycarbonates as bisphenol A in polycarbonate has the potential to be hazardous.

Find out about the manufacturing technique used to injection mold a second material over or around a part to create a new one.

Aerospace. Within aircraft interiors, overmolding enhances passenger comfort and cockpit functionality, seen in armrests, seat cushions, and control grips.

Cast Acrylics are produced by mixing acrylic liquid ingredients in molds. During the production process, the liquid ingredients are pumped into a mold which is then submerged in warm water, and here, the polymerization takes place. Some of its properties are listed below:

In this article, weâll take a look at common factors that influence the cost of injection molding, including equipment, labor, and materials â as well as tips for reducing manufacturing costs.

VEM Tooling has the expertise for your PMMA injection molding project. At VEM Tooling, we ensure that receive a great experience and dependable service! To better understand how VEM tooling can serve you for your PMMA injection molding project, contact us or request a quote today.

Consider shrinkage. Account for material shrinkage differences between the injection-molded part and overmolded material to prevent warping or dimensional inconsistencies.

Industrial tools. Overmolding improves ergonomics in handheld power tools, reducing operator fatigue and enhancing control during industrial use.

Proper wall thickness. Maintain consistent and appropriate wall thickness to ensure even material flow and prevent defects like sink marks or voids.

Improved aesthetics. Different colors, textures, and finishes can be achieved through overmolding, enhancing the visual appeal of products and enabling branding opportunities.

How do you optimize part design for injection molding? This complete guide to designing for injection molding provides basic and advanced design tips, including guidelines for creating snap-fits, living hinges and undercuts, and accounting for optimial surface finishes.

Cast Acrylic is harder than extruded acrylic and is thus, more scratch-resistant. The manufacturing process of casting is labor intensive thus, cast acrylics are more expensive. Cast acrylics are homogenous and therefore have equivalent properties.

PMMA is also a cost-effective alternative to polycarbonate. If polycarbonate is too expensive to be applied to a project, PMMA is an excellent alternative. This is especially the case if the plastic requires a clear appearance bu not the properties of polycarbonate. There are various applications where one would prefer PMMA over polycarbonates such as jewelry, plaques, aquariums, windows, and display pieces. PMMA is comparatively lightweight and inexpensive in such cases.

Acrylic is one of those rare plastics that combine high-performing characteristics with beautiful aesthetics. The aesthetics can be customized according to the designers in the form of color, finishes, and effects. In addition to the furniture and design industry, acrylics are a popular plastic of choice for manufacturing photo frames, clear table tops, and storage plastic parts.

Overmolding involves placing an injection-molded part into a mold and injecting a second material to bond and create a single, integrated product.

es of the polymer, usually targeted toward specific applications. Examples of the properties that can be adjusted in this way are impact resistance, chemical resistance, light diffusion, UV light filtering, or optical effects.

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrinâs properties and how to get the most out of the material.

Tool design. Design molds with appropriate gating, runner systems, and cooling channels to ensure uniform material flow and efficient part production.

Complex design and engineering. Overmolding requires careful design considerations and engineering expertise to ensure proper material compatibility, bonding, and mold design, which can increase development time and costs.

PMMA provides excellent optical clarity, light transmission, and color accuracy which is why it is extensively used in exterior, rear, and indicator light covers of the automotive.

Material compatibility. Choose materials that bond well together and have similar melting temperatures to ensure a strong and reliable bond between layers.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly