Plastics Injection Molding 101: Part 2 - injection molding 101

Author:gly Date: 2024-10-15

Topping the list of plastic mold manufacturers in China is Seaskymedical, a medical plastic manufacturer. It is not a surprise that the company sits on top the list because they provide one-stop injection molding solutions to their clients worldwide. Services they offer include mold design, mold manufacturing, material selection, injection molding, and product development.

Founded exactly 10 years ago, Zhongshan Hord Rapidtools Co.Ltd is equipped with modern injection molding machines and their production base covers an area of over 2,000m². The company has utilized these assets, coupled with its 200+ workforce to effectively serve over 1,000 customers and partners worldwide.

Shuangsheng manufactures both regular and custom-made injection molding equipment. They offer rotary-table, horizontal, and vertical injection molding machines in their wide array of available products. To guarantee that customers can get the most out of their injection molding equipment, Shuangsheng makes sure to provide a variety of services, such as installation, training, and maintenance.

Guangdong Yizumi utilizes its innovative technology to drive an industrial evolution which has seen it go on to win several honors like the 2020 national leading enterprise in High-tech Zone, Annual advanced enterprise of scientific and technological innovation, and a few others.

TK Mold, a china injection molding company is a world leader when it comes to providing game-changing plastic solutions like production of plastic molds and parts to be used in finished products like medical appliances, smart home devices, mobile phones, precise electronics, etc. With 4 decades of existence and development since it was founded in Hong Kong in 1983, this plastic molding company has grown to become a well known brand in China and the Asian continent at large. IPSOS, an independent marketing research company, reported that the revenue TK Global generated from its plastic mold business ranked number one among the Chinese MT3 levels supplies.

This company owns five production plants, four in China which includes its headquarters in Shenzhen and one in Germany. Its production base spreads over a gross floor area of more than 200,000 square meters. TK Mold’s clientele stretches across numerous industries from telecommunication to automobiles, electrical appliances, healthcare, and digital mobile devices.

Xiamen supplies metal and plastic products and also specializes in the production of parts and finishing with several factories dedicated to plastic injection molding, die casting, etc.

Jetting defects in injection molding are another potential result of an uneven solidification process. Jetting occurs when an initial jet of resin enters the mold and has enough time to begin setting before the cavity fills. This creates visible, squiggly flow patterns on the piece’s surface and decreases the strength of the part.

Injection molding is a technique, or a manufacturing process used for producing molded items, that is, parts of a material in larger volumes. This is done by having plastic materials that have been heated to a molten state injected into a mold, cooling them down, and then leaving them to harden. Thermosetting and thermoplastic polymers are the most commonly used materials when it comes to introduction of the injection molding process.

Sositar Mold’s production base is about 3,800m² area with a workforce numbering over 150. The company is capable of producing 60-80 molds each month and has expertise in manufacturing various plastic molds parts for automotive, home appliances, medical equipment, electronics and sporting equipment, as well as general industrial OEM applications. Their facility has the capacity to produce injection molded parts that weigh as much as 1,500g or 650 tons.

Reducing injection pressure is often the best way to ensure more gradual fills, but increasing the mold and resin temperature can also help to prevent any jets from preemptively setting. Placing the injection gate so that the flow of material runs through the shortest axis of the mold is another effective means of minimizing jetting.

Topping the list is none other than Seaskymedical, a professional injection molding manufacturer that prides itself of a state-of-the-art facility and highly skilled team. For all your plastic injection molding parts demands, contact us and enjoy the best service ever.

Eco Molding Co. Ltd provides plastic injection services in different plastic mold designs industries specializing in the production of electronics, general industrial OEM applications, home appliances, and automotive parts. The company offers direct and straightforward factory prices. This helps it maintain utmost transparency which in turn helps it to build trust among its clients.

Asides injection molding, Rilong Precision provides other services which includes but not limited to CNC machined prototypes and membrane switches.

Injection molding warping refers to unintended twists or bends caused by uneven internal shrinkage during the cooling process. Warping defects in injection molding are generally the result of non-uniform or inconsistent mold cooling, which creates stresses within the material.

Zhongshan Hord Rapidtools Co.,Ltd is an expert manufacturing company that deals chiefly in raid tooling and small volume production like CNC machining, aluminum pressure die casting, aluminum extrusion, silicone heat compression, and production of plastic mold in china.

Located in Huangyan, Zhejiang Province of China, JMT Automotive Mold Co.Ltd is one of the top china plastic molding suppliers in the country and with 21 years of existence, the company has provided quality satisfaction to its customers. JMT Automotive Mold specializes in the production and design of mold parts for the automotive industry. They are also popular for SMC (Sheet Molding Compound) mold, home appliance mold, and household products mold.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Injection molding is an efficient production method when high volumes of identical parts are needed. However, it also requires a high degree of technical expertise to master. With so many different variables in play, small, seemingly minor mistakes in early phases of product development can lead to major problems — and even compromise product integrity — down the line.

Dongguan Rusheng Plastic Hardware Co., Ltd is a subsidiary of the Yuzin Group of companies (same parent company as Yuzhexin Hardware Plastic Product Co., Ltd) and was founded in 1996 in Guangdong Province. Rusheng is one of the companies that make plastic injection molding in China. It sits on a total area of about 35,000 square meters and the workforce is 1,200 members strong.

With its headquarters in Shenzhen, China, Shenzhen Silver Bass Technology Ltd is a renowned force in the automotive industry and has supplied car manufacturers with large automotive interior parts mold, exterior parts mold, automobile function parts mold, and even automobile security system parts mold.

Flow lines are off-color lines, streaks, and other patterns that appear on the surface of a part. These are caused by the shot of molten plastic moving at different speeds throughout the injection mold, which ultimately causes the resin to solidify at different rates. This is often a sign that injection speed and/or pressure are too low.

“Short shots” refer to instances in which the resin doesn’t entirely fill the mold cavity, resulting in incomplete and unusable parts.

Opting for plastic injection manufacturers in China is a common decision that many big companies around the world make. There are a few valid reasons why this is so. Below are some of the benefits of choosing injection molding:

Located in Ningbo City, the South Yangtze River economic center, Shuangsheng Plastic Machinery is one of the biggest and most trusted injection mold companies in china. Having been in operation since 1999, Shuangsheng Plastic company has developed to produce a wide range of machines for injection molding.

Sositar Mold Co. Ltd have almost 25 years under their belts in active Industry presence as a china plastic molding company. The company is an expert in the production of different mold parts for home appliances, electronics, sporting equipment, medical equipment, automotive, and even general industrial OEM application.

Aside from its high-speed precision injection molding machines, Guangdong Zhen Xiong Machinery also offers a wide range of other products and services to its customers. These products include high-speed precision molds, high-speed precision robots, and molding process solutions.

To encourage delamination repair and prevention, teams should increase mold temperatures and tailor the mold ejection mechanism to be less dependent on mold-release agents, since these agents can increase the risk of delamination. Properly pre-drying the plastic before molding can also help.

Choosing a manufacturing partner like SyBridge, who is well-versed in common defects in injection molding and their troubleshooting, can mean the difference between high-quality parts — produced on-time and within budget — and those marked with weld lines, jet, flash, sink marks, and other defects. In addition to being an experienced on-demand manufacturing shop, we also provide design consulting and optimization services that ensure we’re able to help every team create functional, elegant, high-performance parts as efficiently as possible. Contact us today to learn more about our injection molding services.

Xiamen Aria Baby Industrial Co., Ltd. is a Chinese injection mold company that was established in 1986. The company has a staff strength of 1,000 people and two production bases that measure more than 100,000 square meters.

The company makes use of uncomplicated and energy saving technologies which amounts into what the clients want, a highly efficient, low cost machine with optimal performance over a long period of time. Most equipment from Haitian International are produced with energy efficiency and environmental protection in mind. The company is committed to offering clients high-quality goods and services and works tirelessly to upgrade its goods and operational procedures in order to satisfy the shifting demands of the market.

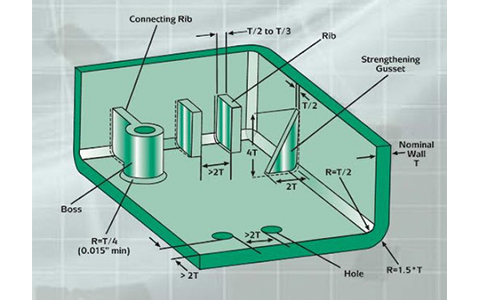

On the design side, the risk of sink marks can be minimized by ensuring proper injection molding rib thickness and wall thickness. These actions can also help to increase the overall strength of the part.

With over 100 staff on ground, more than 2,000 square meters in area, and capital assets worth over 8 million RMB, Eco Mold Co. Ltd has the capacity to manufacture between 40 to 50 plastic injection molds every month.

Zhen Xiong Machinery is a Chinese company that produces some of the best injection molding machines in china. Founded in 1993, this company has been able to rack up a lot of experience to establish itself as an industry authority. Zhen Xiong Machinery is experts in the production of high-speed injection molding machines, which are meant for the mass creation of a variety of products. This works by injecting molten material into a mold.

With more than 50 years of service, this company manufactures a wide range of injection molding machines, which includes hybrid models, electric models, and traditional hydraulic models. The range of products made by Haitian International goes from custom-made machines to standard ones which can be used to mold a wider range of products.

One of the best plastic injection manufacturers in China is Guangdong Yizumi, a company that has been operating in Foshan city of Guangdong Province since 2002, and ever since then, it has grown to be one of the top companies. Yizumi is mostly known for its production of durable and high grade injection molding equipment and machines. The company manufactures a broad array of products and services which includes both custom and standard machines.

Preventing warpage defects in injection molding is a matter of guaranteeing that parts are given enough time to cool — and at a sufficiently gradual rate — to prevent internal stresses from forming and damaging the piece. Uniform wall thickness in mold design is crucial for many reasons, critical among them being that it helps ensure that the plastic flows through the mold cavity in a single direction.

Shenzhen Silver Bass Technology is a foremost china injection molding company that engages in the fabrication of mold and generally, the production and development of precision technology. Since its establishment in 1993, the company has offered a worldwide tooling and molding solution for precision structural components and large precision injection molds. This china plastic molding company has fabricated molds all while partnering with global brands like Peugeot and ZTE.

Richfields is equipped with high class tooling and molding facilities which gives them the chance to offer their global clientele one of the most competitive prices they can get anywhere.

What causes short shots in injection molding? Typically, they are the result of restricted flow within the mold, which can be caused by gates that are too narrow or have become blocked, trapped air pockets, or insufficient injection pressure. Material viscosity and mold temperature are also contributors. Increasing mold temperature and incorporating additional venting into mold design to allow air to properly escape can help prevent the occurrence of short shots.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Flow lines can also appear when the thermoplastic resin moves through parts of the mold with different wall thicknesses — which is why maintaining consistent wall thickness or ensuring that chamfers and fillets are an appropriate length is critical. Placing the gate in a thin-walled section of the tool cavity can further help to reduce flow lines.

Most household and industrial utility tools consist of a plastic part, if not sometimes entirely made of plastic. World class manufacturing brands have over the years turned to Chinese companies for their injection molding needs. This is not much of a surprise because China is an industrial powerhouse as it boasts of one of the world’s biggest labor forces and a large pool of experts in china plastic injection mold. With a sea of injection molding companies in operation, for your ease, we have compiled a well researched list of the top 15 China molding companies.

Though most often an indicator that the plastic needs more time inside the mold to properly cool and cure, sink marks may sometimes be remedied by reducing the thickness of the thickest wall sections, which helps to ensure more even and thorough cooling. Inadequate pressure in the mold cavity or higher-than-desirable temperatures at the gate can also contribute to the development of the defects.

What is delamination? Delamination is a condition that causes a part’s surface to separate into thin layers. These layers, which appear like coatings that can be peeled off, are caused by the presence of contaminants in the material that do not bond with the plastic, creating localized faults. An over-dependence on mold release agents can also cause delamination.

Sink marks appear as depressions, dents, or craters in thick sections of a part. Thicker sections take longer to cool, which can have the often unanticipated side effect of the inner portions of the part shrinking and contracting at a much different rate than the outer sections.

Haitian International manufactures high quality mold injection machines for normal applications both in the average and peak aspects of the plastic processing industry.

Also called knit lines, these defects mark where two flows of molten resin came together as they moved through the mold geometry. This happens around any part of the geometry that has a hole. As the plastic flows and wraps around each side of a hole, the two flows of plastic meet. If the temperature of the flow isn’t just right, the two flows won’t properly bond together and will instead cause a visible weld line. This reduces the overall strength and durability of the component.

Defects can reduce the speed and cost-efficiency of the entire product development process, and can potentially shorten product life spans if left unchecked. Injection molding issues and defects can be caused by a host of reasons, including poor design, production process mistakes, quality control failures, and more. As such, it’s important to take a proactive approach to risk mitigation throughout the product development process so as to reduce the chances of potential injection molding defects.

Here are a few of the most common defects that may occur in plastic injection molding — and how product teams can avoid them.

Eco Molding Limited is a china injection mold company that in over its 10 years of operation has speedily established itself as a big player in the china plastic injection molding industry. Fueled by its large and dedicated workforce, world-class infrastructure, and a capable management team, Eco Molding Company Limited is proudly a trusted custom plastic molding company that supplies injected parts globally, including North America and Europe.

In summary, China is home to tons of injection molding companies that offer unique capabilities and services but we’ve streamlined the list to the top15 companies that can offer you the best products and services you need.

With over 10 years in production and more than 11 years inherited from the parent company, this injection mold company china is one of the few medical injection molding companies that focus mainly on the production of injection mold for the health sector. Seaskymedical has met the stringent needs and the diverse challenges that abide in the medical field. The manufacturing company is equipped with an ISO 8 certified production site that guarantees injection molding in clean rooms and 10 cutting-edge injection molding equipment to produce the best china plastic injection mold.

Injection molding can be a highly efficient manufacturing method for producing highly repeatable plastic parts, but, as with many processes, producing high quality end-parts requires a high level of attention to detail and a proactive approach to risk management. Everyone involved in the product development process — from the initial design and proof-of-concept stages all the way to fulfillment — needs to do their due diligence to ensure products meet the highest quality standards and avoid these common plastic injection molding issues.

Raising the temperature of the molten resin can help to prevent the solidification process from beginning too soon, as can increasing injection speed and pressure. Resins with lower viscosity and lower melting points are less prone to developing weld lines in injection molding, which can also be eliminated by removing partitions from mold design.

Richfields is an injection molding company that was founded in 2001 and was initially into plastic injection molding alone. However as the years went by the company has advanced to producing the molds themselves. Currently, Richfields Plastic Limited manufactures more than 300 molds to be exported every year.

Haitian International Holdings Ltd., is a leading body in the production of injection-molding machines which its subsidiary firm, Haitian Plastics Machinery Ltd, is directly responsible for.

In addition to injection mold service china, they offer finished components and goods, including shopping carts, baby rockers, plastic injected and extruded parts, aluminum cases and playpens, and many other things.

With over 3,000 workers in its production bases around the world that covers an area totalling close to 600,000 square meters, Guangdong Yizumi is not only a force to reckon with in China, it is also at the forefront of the trade globally. YIZUMI was the first company doing injection molding in China to get listed on A Shares at the GEM of Shenzhen Stock Exchange on January 23, 2015

Founded in 1990, initially as a supplier of high precision plastic injection parts, Rilong Precision Mold Co.Ltd is now not only one of the top injection molding companies in China, it is also a big player in the manufacturing of rubber products. Over 300 highly skilled officials currently work in the facility to ensure they only put out the best if the best.

This company provides its customers around the world with customized machines like the precise small and medium size injection molding machines, two color plastic flower making injection molding machines, full electric injection molding machines, color chips making injection molding machines, and several others.

This company sits comfortably on a 23,000 square meters expanse of land and it is one of China’s largest innovative plastic injection molding companies in china. JMT Automotive Mold Co. equips its facilities with some of the worlds best class processing equipments, some of which includes Taiwan high-speed milling machining center, over 10 Haitian injection molding machines, five axis high-speed machining center, three coordinate detector, high precision double-head EDM, material hardness detection, 50 CNC processing equipment amongst several others.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly