Plastic Prototypes Using Silicone Rubber Molds - mold and plastic

Author:gly Date: 2024-10-15

Once the tooling is accepted, sea or air freight will be arranged and all necessary shipping and customs documentation prepared. Tooling is shipped from China to Plastech UK where it is re-checked and inspected before being forwarded to the client for commissioning. The tool will be supplied with a full set of CAD data and steel certificates. Tooling is guaranteed to client requirements under the terms detailed in the final accepted quotation.

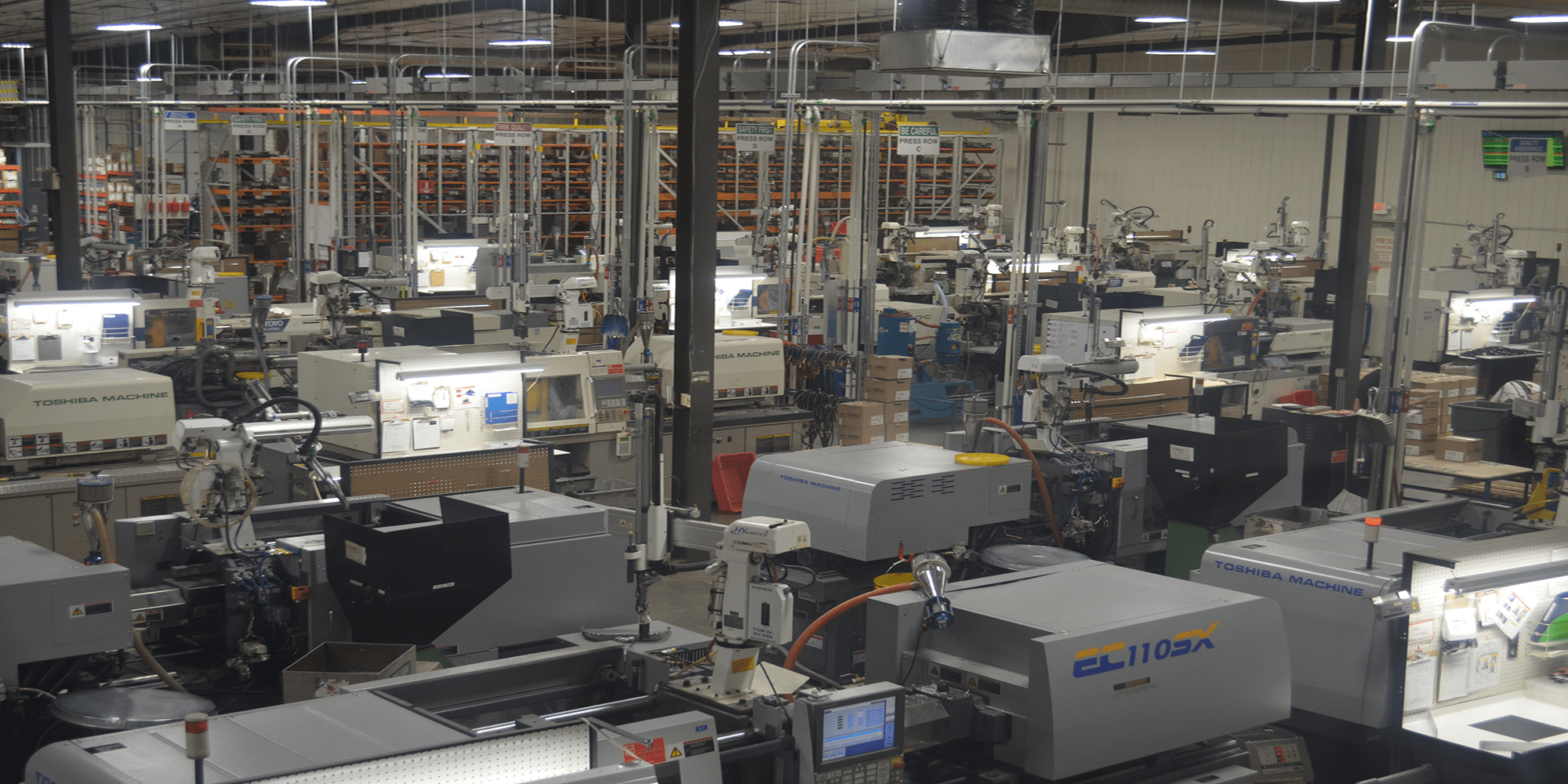

With over 50 all-electric presses, we have a wide range of custom injection molding solutions serving a range of strategic markets, Vital Plastics has been focused around providing customers with a comprehensive solution to their plastics needs. As technology and markets continue to evolve we stay committed to reinvesting back into our infrastructure and expanding our resources so we can always provide the best available value in the custom injection molding supply chain. Whether our customers have simple shoot and ship type of products, or comprehensive assembly and value add opportunities we welcome the opportunity to showcase our extensive engineering and technology services.

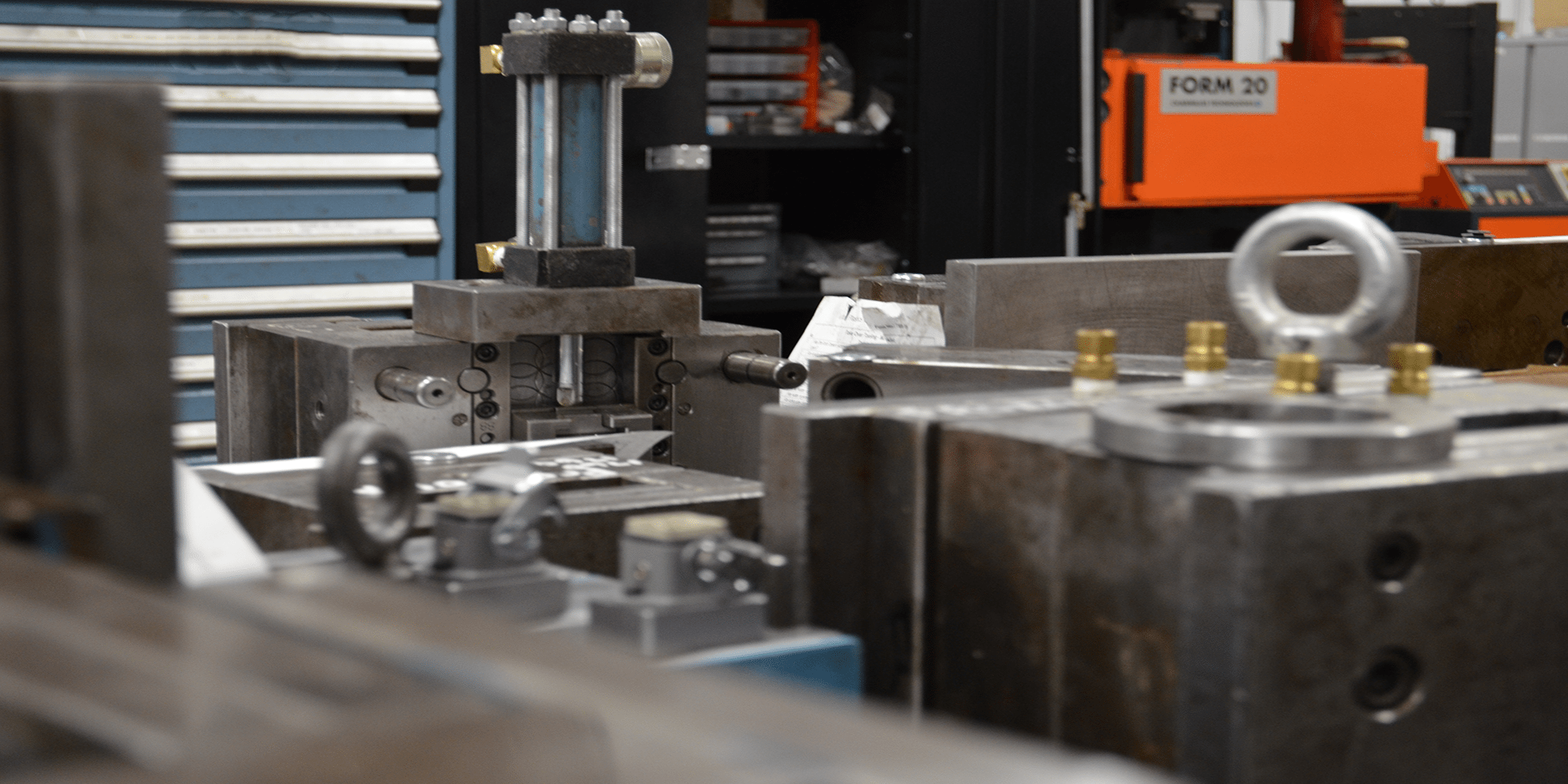

Plastech specialises in the manufacture of mould tooling from prototype to full high volume tools. We produce variations including:

Strategically located East of Minnesota’s Twin Cities metro area on Interstate I-94, Vital Plastics, Inc. is an industry leader in Thermoplastic Injection Molding and Contract Assembly. Since 1994, Vital Plastics is focused on providing above and beyond customer service, design & engineering assistance, and quality parts, on-time.

We look forward to being your manufacturing partner on your journey to improve your efficiencies and your profitability. Our goal is to help unclutter your manufacturing floor; resulting in greater yields. With our two manufacturing facilities we are the perfect size. We’re large enough to handle your high-volume molding & assembly needs, yet small enough to focus on customer-specific requirements.

Plastech has more than 30 years’ experience and knowledge in design, sourcing and manufacture of mould tooling. All mould tooling manufacture is managed, monitored and checked by UK personnel on site in China to ISO 9000 quality standards.

A plastic injection molding and contract assembly company providing customers with high value manufacturing services. Specializing in high-volume injection molding with the full complement of equipment including presses ranging in size from 30 tons to 400 tons capacity.

Tooling is manufactured at Plastech China. All tooling is guaranteed to client requirements and supported by Plastech UK engineers. Plastech China tool rooms are accredited to ISO 9000 quality standards.

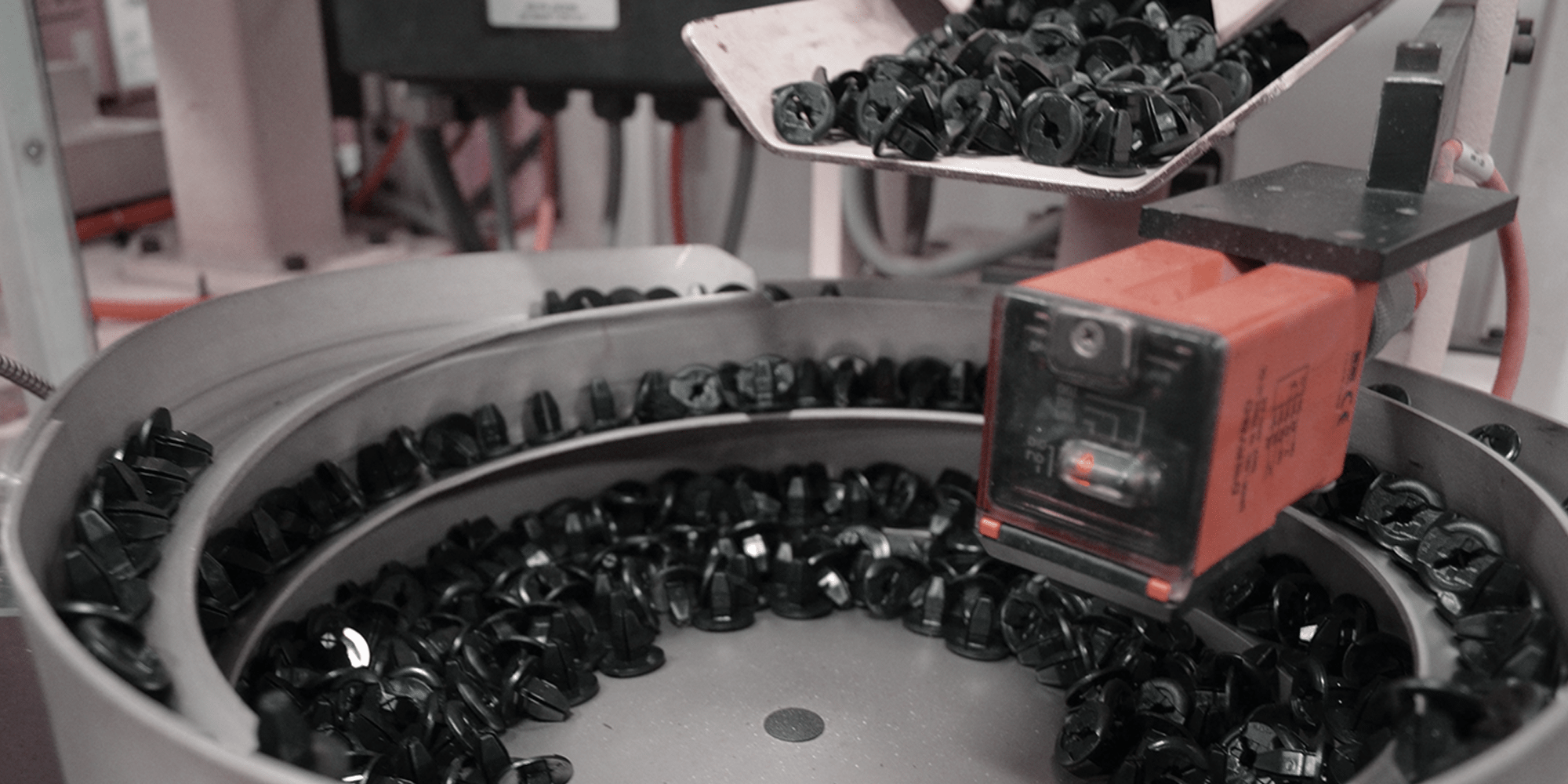

Our large volume assembly services eliminate any middle men. This provides one resource and offers a cost effective solution. We utilize fully automated assembly machines we have bought or built ourselves as well as utilizing customer supplied equipment. In cases where the volume doesn’t warrant the expense of fully automated machines, we’ll utilize our semi-automatic equipment or hand-set assembly as a viable option.

To enable clients to closely monitor the progress of their tooling, Plastech China produces weekly plans and images. Plastech will also forward samples for your appraisal, along with video footage of trial and inspection reports. For clients who wish to witness trials first hand, we can arrange visits, organise and obtain visas, book hotels and arrange transport and translation services.

With nearly 70,000 sq. ft. of climate controlled manufacturing space, and an additional 6 acres of land for future growth, no project is too big or too small for our team to handle. We utilize all-electric injection molding machines, for process efficiency and consistency, ranging in size from 30T to 400T.

Vital Plastics is a plastic injection molding company with contract assembly capabilities dedicated to providing our customers with high value manufacturing services. We specialize in high volume injection molding with our full complement of equipment ranging in size from 30 tons to 400 tons capacity. From prototypes to production. Our number one goal is to exceed your injection molding & assembly requirements. We utilize Cellular Manufacturing for all of your plastic injection molded components, ensuring each part you receive gets the attention to detail you deserve. We also have more than 250 people on our assembly team, whether you need automatic, semi-automatic or hand-set assemblies.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly