Plastic Injection Moulding Quote UK - plastic injection moulding service

Author:gly Date: 2024-10-15

We’re committed to delivering turn-key manufacturing solutions for customers with defense and aerospace plastic injection molding needs. Our services include traditional and two-shot injection molding, 3D printing for steel mold inserts, and a wide range of secondary services.

Enhancing Electronic Products with Vacuum Casting Technology In the fast-paced world of electronics, precision and quality are paramount. The demand for innovative and reliable electronic

The Future of Automotive Parts: How 3D Printing is Transforming the Industry In the fast-paced world of automotive manufacturing, innovation is key to staying ahead

In the aerospace and defense industry, precision, reliability, and performance are paramount. At Westec, we specialize in providing high-quality injection molding solutions tailored to meet the stringent demands of aerospace and defense applications. With more than 50 years of experience behind us, we know how to leverage our state-of-the-art injection molding technology and rigorous quality control processes to ensure the highest level of precision and accuracy in every part we produce.

Best Dual Extruder 3D Printers in 2024 3D printing technology continues to evolve rapidly, offering new capabilities and enhanced performance. One of the most significant

Exploring Metal Filament 3D Printing: The Future of Additive Manufacturing Introduction In the ever-evolving landscape of 3D printing, metal filament 3D printing has emerged as

Exploring the Fascinating World of Infill Patterns in 3D Printing 3D printing has revolutionized the way we create objects, allowing us to transform digital designs into

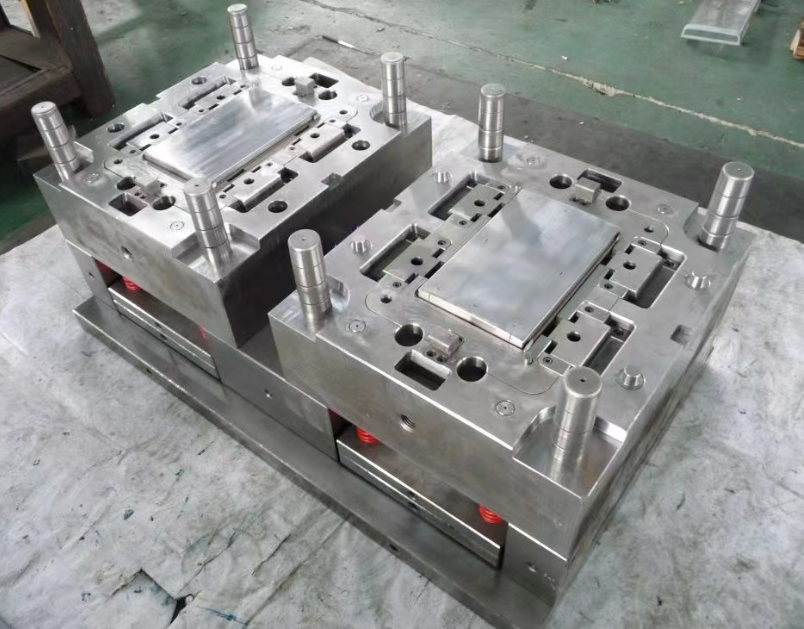

In practical applications, the selection of injection mold materials should be based on the specific production environment and workpiece requirements, taking into account various factors, including:

At Westec, we pride ourselves on our ability to produce injection-molded components that meet the most exacting standards of precision and accuracy. Our advanced injection molding technology and quality control measures ensure that every part we produce performs flawlessly, even in the most demanding applications. Our presses range from 28 to 610 tons. And, with operations that run 24/7, we have the capabilities to deliver scalable, flexible, versatile solutions, no matter how demanding your requirements are.

In the world of manufacturing and plastic production, injection molding plays a vital role in creating a wide range of products we use every day. Central to the success of injection molding is the selection of the right materials for the molds. These molds are responsible for shaping and forming the molten plastic into the desired product, making the choice of materials crucial for achieving desired outcomes.

FreeCAD vs. Autodesk Fusion®: Which CAD Software Reigns Supreme? When it comes to computer-aided design (CAD) software, two names often come up: FreeCAD and Autodesk

Exploring Shapeways Alternatives: Finding the Right 3D Printing Service for You In the rapidly evolving world of 3D printing, Shapeways has established itself as a prominent

CREO vs. SolidWorks®: A Comprehensive Software Comparison In the world of computer-aided design (CAD), two names frequently rise to the forefront: CREO and SolidWorks®. Both

In conclusion, the selection of injection mold materials should consider multiple factors and make the most suitable choice based on the actual situation to ensure the production of high-quality, efficient, and safe plastic products.

Exploring the Best 3D Printing Settings for HIPS High Impact Polystyrene or HIPS is a standout choice in the world of 3D printing. Known for

As a trusted provider of defense and aerospace plastic injection molding solutions, we believe that having advanced materials expertise isn’t a perk—it’s a necessity. At Westec, we offer unparalleled expertise in working with high-performance and engineering polymers including PEEK, Polysulfone, Ultem, to name only a few. With the right material, we aim to deliver injection molded parts that meet your every strength, durability, and performance requirement.

Exploring the Best Desktop CNC Milling Machines In recent years, desktop CNC milling machines have revolutionized the way hobbyists, makers, and professionals approach fabrication. These

The Best CAD Software for 3D Printing: A Comprehensive Guide In the dynamic world of 3D printing, choosing the right CAD (Computer-Aided Design) software is

IN3DTEC rapidly delivers prototyping & scaled production on demand to help project designers and engineers accelerate new product introduction. We make excellent products from your ideas.

At Westec Plastics, we’re one of the only privately-owned and locally operated injection molders in the Bay Area of California. We’re proud to be a single-source provider of traditional and two-shot injection molding services, clean room injection molding, 3D printed steel mold inserts, in-house tooling maintenance and repair, and a variety of secondary services. We’re also versatile in our capabilities, so whether you need micro components or large parts, low or high-volume, we have everything we’ll need to get the job done. Get started with us today.

Keep posted on the release of Coupon Code. The latest news of 3D Printing, CNC Machining, Injection Molding, and Silicone Molding…

100 Innovative 3D Print Projects You’ll Love Introduction In the ever-evolving world of technology, 3D printing stands out as a revolutionary tool that empowers creators,

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly