Plastic Injection Moulding - injection moulders

Author:gly Date: 2024-10-15

Once a scientific molding process is established, the process outputs are meticulously documented and optimized, which greatly simplifies troubleshooting and allows injection molding processes to be easily transferred to different molding machines.

We also offer exclusive, modular training packages that group our most popular Scientific Molding training courses — at significant savings when compared to purchasing the courses individually.

Routsis’s Scientific SkillSet™ Series is a unique learning experience that combines detailed, step-by-step online instruction with practical hands-on labs and worksheets. Each of the twenty-six course/worksheet combinations focuses on developing important processing skills related to troubleshooting, optimizing, and documenting an injection molding process.

Properly documenting an injection molding processes is much more involved than simply jotting down machine settings. A “scientific” approach to process documentation primarily focuses on machine-independent process outputs — allowing you to quickly establish a given process on virtually any molding machine. Scientific process documentation also makes it easy for technicians to compensate for material variations and changes in processing conditions.

It’s simple: Routsis’s extensive experience in Scientific Molding consulting and training uniquely positions us to help your company decrease scrap and downtime while improving molded part quality. For over 30 years, we’ve been helping injection molders develop robust and reliable processes — improving their parts and maximizing their profits.

The concept of Scientific Troubleshooting is quite straightforward: Determine what has changed in the process and then return the process back to the documented standard. If the process cannot return to the documented standard, the technician determines the specific condition that’s preventing this and corrects it. This returns the process back to the standard — and allows the machine to resume making good parts for the customer.

Our technologies help create items that make daily life easier for consumers. We enable you to bring products to the market quickly and affordably, with a keen eye to sustainability.

M-Powered, Milacron’s industry-leading digital solution, helps customers improve performance, control costs and reduce risk on their Milacron Injection Molding & Extrusion machines.

Available in twin conical (TC) or twin parallel (TP) screw configurations, Milacron Twin Screw Extruders are quality built for reliable, long-term operation.

The Routsis SmartTech™ program is the most effective hands-on training program for plastic processors and technicians. This unique combination of face-to-face instruction, online training, and hands-on skill development focuses on the science of injection molding — not just on the workings of a particular injection molding machine. Two-thirds of the time is spent at the machine, making it a better way to help your company improve its efficiency, profitability and competitive position.

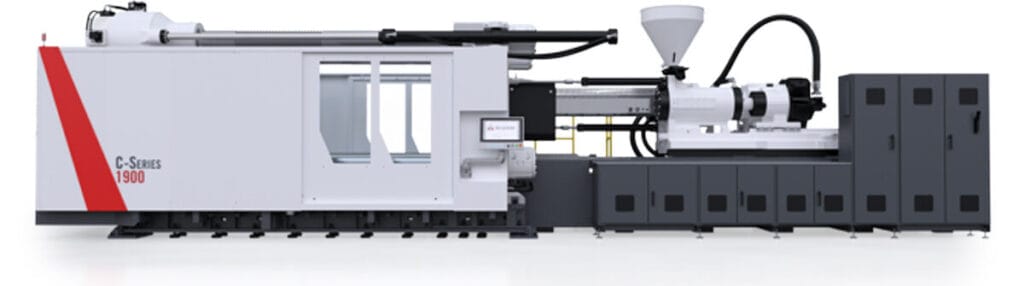

A large-part powerhouse, the C-Series enhanced machine specifications offer improved reliability, higher max mold weights, and faster clamp speeds.

Milacron technologies manufacture a vast array of automotive parts, both large and small, with a focus on keeping parts durable, lightweight, and fuel efficient.

A scientific process is a more profitable process. By allowing technicians to quickly identify, isolate, and correct molded part problems, a properly maintained Scientific Molding process reduces scrap and eliminates unnecessary downtime. This results in an increase of efficiently-produced, defect-free molded parts — and happier customers.

This exclusive training approach allows companies to perform the same type of classroom learning found in popular seminars in the comfort of their own production environment.

Scientific Molding is a data-driven approach to developing, documenting, maintaining, and troubleshooting an injection molding process. Unlike traditional injection molding, Scientific Molding separates — or “decouples” molding processes into First Stage Filling, Second Stage Packing/Holding, and Cooling/Recovery. By identifying and isolating separate molding phases, a Scientific Injection Molding process minimizes shot-to-shot variation, improves molded part consistency, reduces scrap, and improves energy efficiency.

Turning technicians into good scientific molders only requires a few basic steps. First, provide them with a strong foundation of scientific processing concepts. Next, help them develop accurate and repeatable documentation skills. Finally, they’ll need strong scientific troubleshooting skills to identify the problem, interpret the process documentation, isolate what’s changed, and ultimately return the process to the approved standard.

Milacron has a wide range of plastic injection molding machines and plastic processing technologies that give manufacturers in the construction industry a competitive edge.

We help our customers create innovative and unique packaging that is attractive and functional. Milacron technologies offer cost-effective solutions that help you stand out from your competitors.

Most injection molding facilities already have all the equipment they need to run efficient, repeatable Scientific Molding processes. What’s really needed is a Structured Training Plan. Ongoing employee training is essential for instilling a company-wide commitment to quality and creating a culture of excellence. A strong in-house training program equips your technicians and engineers with the advanced processing skills they need to establish, maintain, and document Scientific Molding processes.

The global construction industry relies on Milacron’s plastic processing solutions to produce materials that are lighter-weight and made with recycled materials. We also offer a range of technologies that create durable and easily maintained materials for construction applications.

Our reclamation solutions help you get more from your materials and help extend the life of your machine and its components.

From clear-room systems to high-precision machinery, Milacron's plastic processing solutions help produce new medical technologies and generate advances in the high-demand medical industry.

More than machines, we are complete lifecycle partners. From PO and PVC pipe to advanced building materials, we focus on helping you leverage our technologies to optimize your processes, increase your production, and maximize your profits.

The Courtesy Plus maintenance program ensures you are ahead of any issues that could affect your operations, leading to performance, safety, and value improvements.

Utilizing our Structural Foam, Structural Web, Gas Assist, or Solid Molding technologies, the L-Series features a heavy-duty modular design that allows you to streamline your process and increase your production.

Routsis has the largest library of online Scientific Molding training courses in the world. With courses that include material drying, material purging, process parameters, troubleshooting, and robotics, our extensive catalog of Scientific Molding training programs will help your employees successfully establish, document, and maintain a robust Scientific Injection Molding process.

Milacron’s latest technologies in rapid product development cycles meet the demand for superior part quality, precision, and ever-smaller components at lower costs.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly